Multi-stage planetary transmission

A planetary structure and transmission technology, which is applied in vehicle gearboxes, multi-ratio transmissions, transmissions, etc., to achieve the effects of small structural component loads, improved efficiency, and small construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

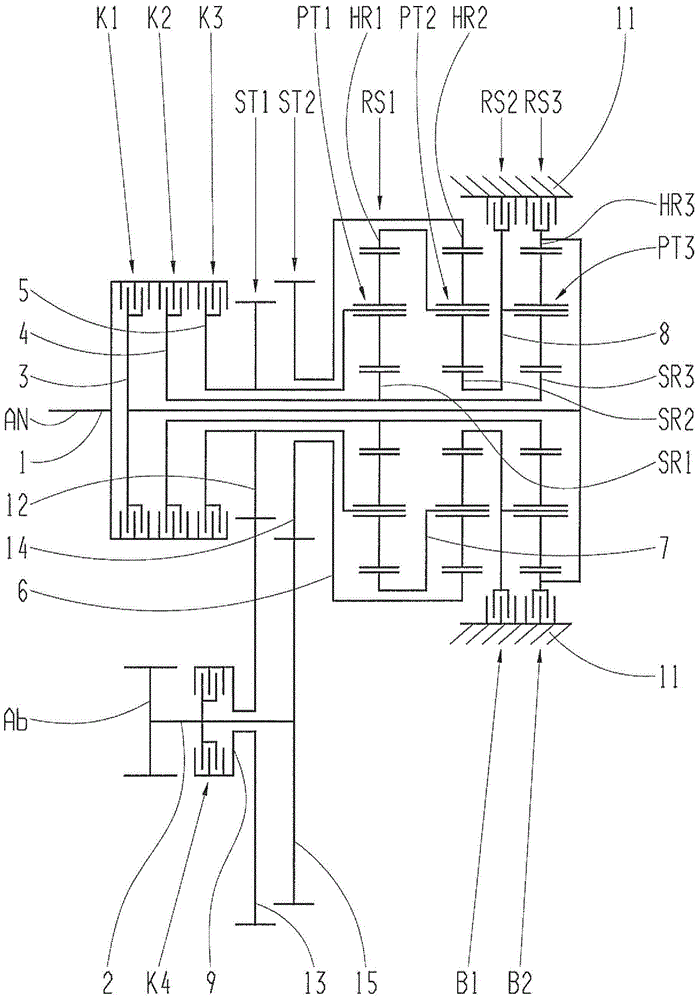

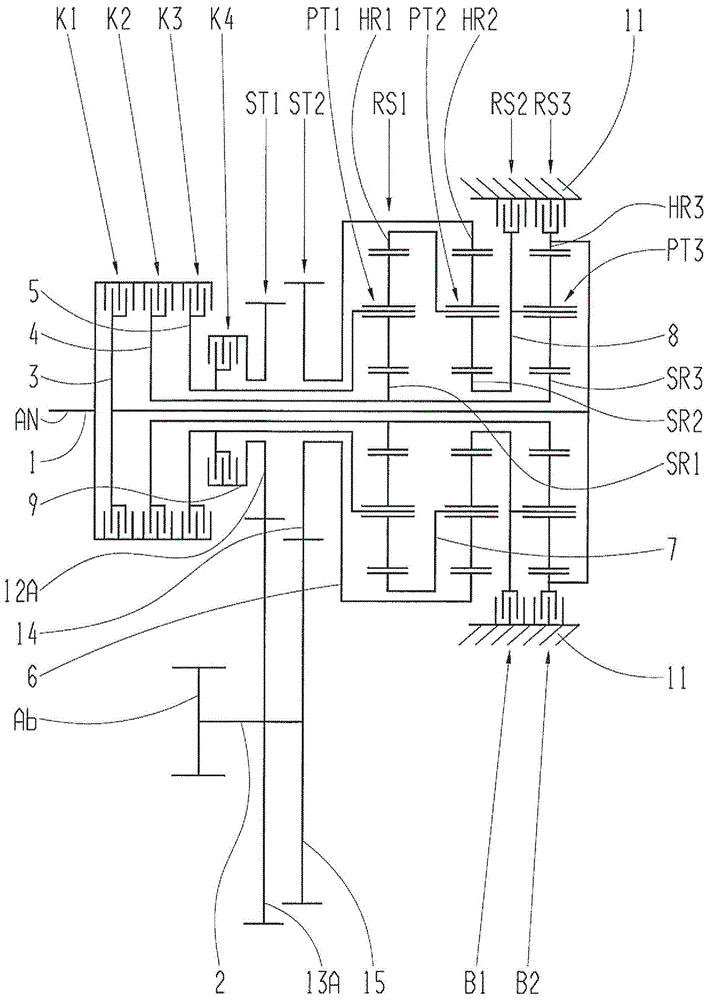

[0019] exist figure 1 and figure 2 A variant embodiment of a planetary multi-stage transmission for a vehicle according to the invention (for example as an automatic transmission or automatic transmission) is shown by way of example in each case.

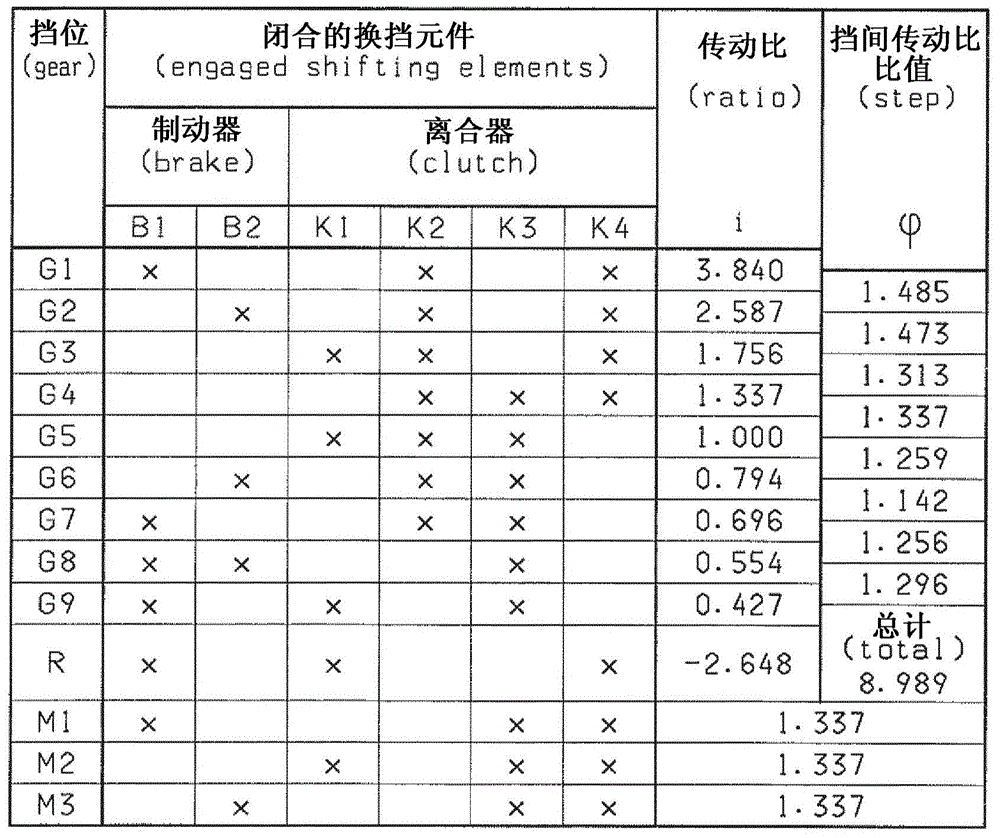

[0020] Independently of the corresponding variant embodiment, the multi-stage transmission comprises a only schematically indicated housing 11 with a first shaft 1 as drive element An and a second shaft as output element Ab arranged axis-parallel thereto. 2 and another seven axes 3, 4, 5, 6, 7, 8, 9. In addition, a first planetary gear set RS1, a second planetary gear set RS2 and a third planetary gear set RS3 are provided. For shifting several gear stages, a first shifting element K1 embodied as a clutch, a second shifting element K2 embodied as a clutch, a third shifting element K3 embodied as a clutch, a fourth shifting element embodied as a clutch are provided The element K4, the fifth shifting element B1 designed as a brake...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com