Planetary structure multi-speed transmission

一种行星结构、变速器的技术,应用在车辆变速箱、多传动比传动装置、传动装置等方向,达到节省布置、小构建耗费、节省轴向结构空间的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

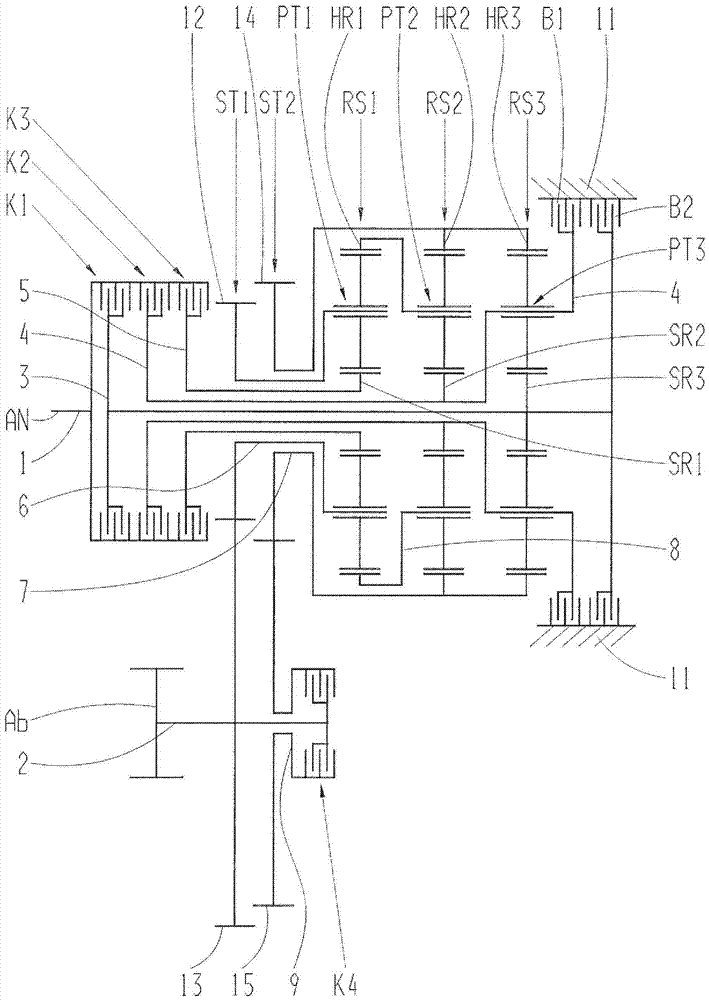

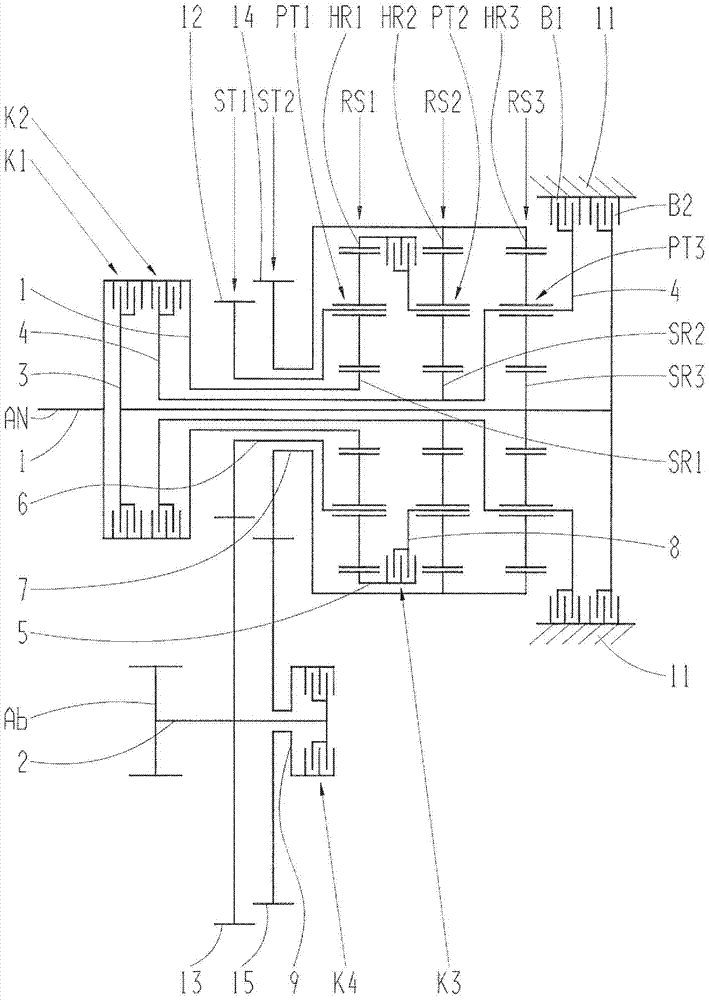

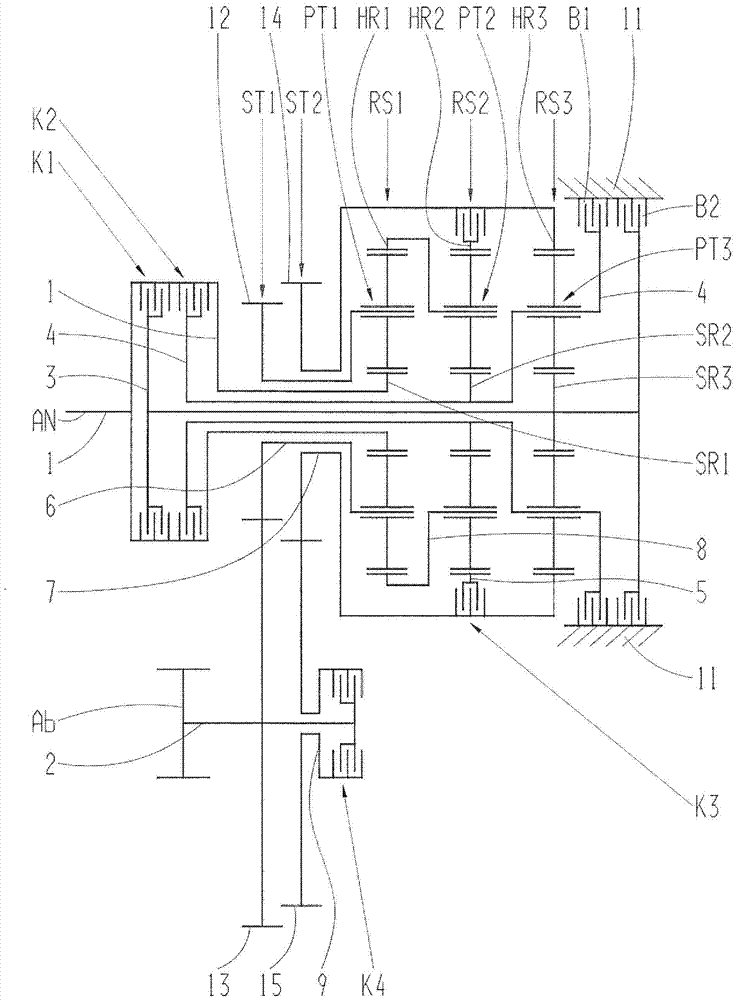

[0025] exist Figure 1 to Figure 6 In each of the variant embodiments of the planetary multi-stage transmission for vehicles according to the invention (for example as automatic transmission or automatic transmission) are shown by way of example, in these variant embodiments, the third clutch implemented as a clutch is shown Different positions of the shifting elements.

[0026] Independently of the corresponding variant embodiment, the multi-stage transmission comprises a only schematically indicated housing 11 with a first shaft 1 as drive element An and a second shaft as output element Ab arranged axis-parallel thereto. 2 and another seven axes 3, 4, 5, 6, 7, 8, 9. Furthermore, a first planetary gearset RS1 , a second planetary gearset RS2 and a third planetary gearset RS3 are provided, which are preferably designed as negative planetary gearsets. For shifting several gear stages, a first shifting element K1 embodied as a clutch, a second shifting element K2 embodied as a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com