Stepless speed change mechanism

A technology of continuously variable speed change mechanism and speed control mechanism, which is applied to mechanical equipment, transmission parts, gear transmission devices, etc., can solve the problems of complex structure, difficult maintenance and high manufacturing cost, and achieve a wide speed control range and low manufacturing cost. , Simple and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

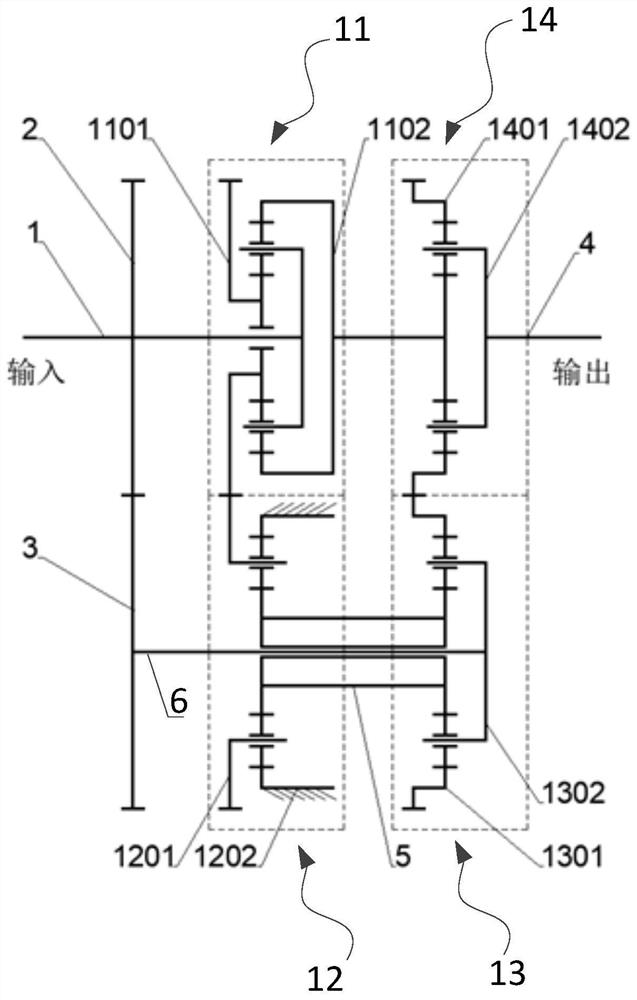

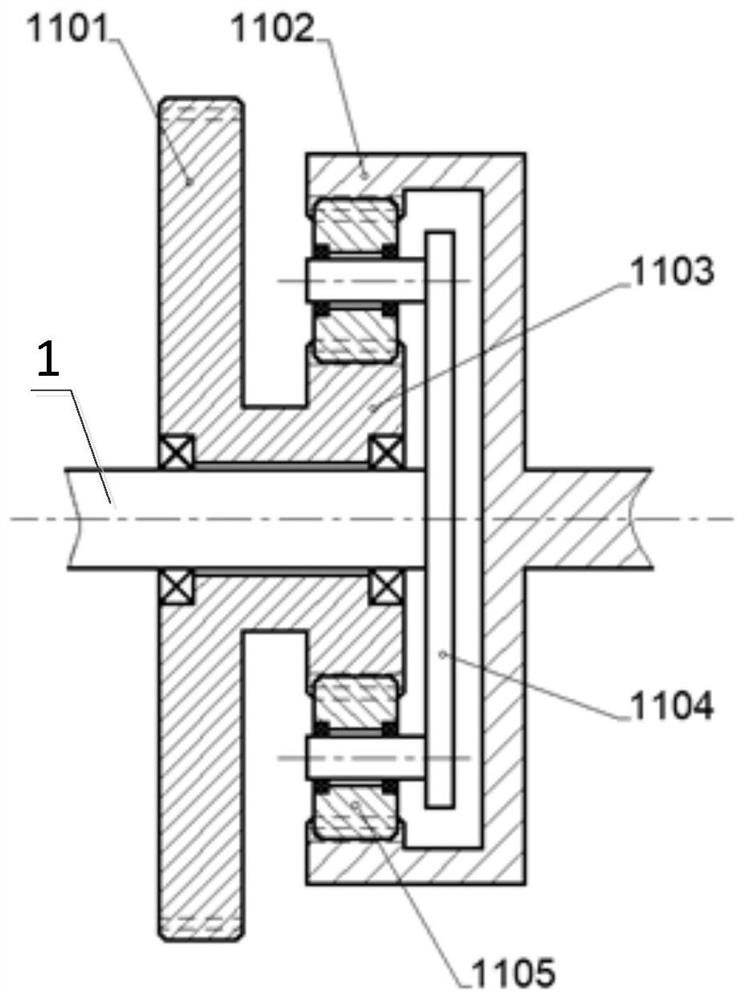

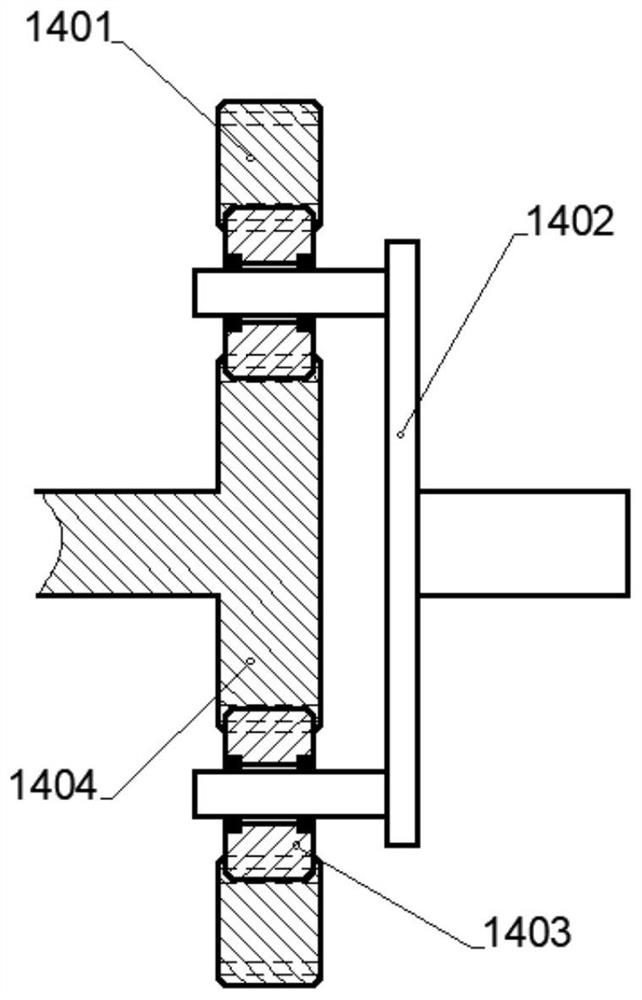

[0018] see figure 1 , this embodiment provides a continuously variable transmission mechanism, which includes an input shaft 1, an external gear 2, an external gear 3, a first mechanism 11, a second mechanism 12, a third mechanism 13, a fourth mechanism 14, an output shaft 4 and speed regulating mechanism 5. Wherein, the input shaft 1 is connected with the external gear 2 and the first mechanism 11 respectively; the first mechanism 11 is connected with the fourth mechanism 14; the external gear 2 meshes with the external gear 3; the external gear 3 is connected with the third mechanism 13; the second mechanism 12 Connected with the third mechanism 13; The first mechanism 11 is connected with the second mechanism 12; The third mechanism 13 is connected with the fourth mechanism 14; The output shaft 4 is connected with the fourth mechanism 14; The speed regulating mechanism 5 is respectively connected with the second mechanism 12 and The third mechanism 13 is connected.

[001...

Embodiment 2

[0026] see figure 1 , Figure 4 to Figure 6 , the difference between the continuously variable transmission mechanism provided by this embodiment and Embodiment 1 is that this embodiment is a structural member (7) that integrates the sun gear (1204) and the sun gear (1304) of Embodiment 1, that is, the sun gear The wheel (1204) and the sun gear (1304) form a structural member (7), rather than two separate structural members, so that the second mechanism (12) is connected with the third mechanism (13) through a structural member (7) ; Correspondingly, the speed regulating mechanism (5) is respectively connected with the second mechanism (12) and the third mechanism (13) through the structural member (7); one end of the connecting shaft (6) is connected with the external gear (3), and the connecting shaft The other end of (6) is connected with the planet carrier (1302) after passing through the gear (1201) and the structural member (7). In practical application, the speed regu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com