Optimum-speed full-automatic fried dough twist machine

A fully automatic, twist machine technology, used in engine components, engine sealing, dough twisting machinery, etc., can solve the problems of wasting manpower, material resources and time costs, difficult to ensure the position accuracy of parts, and scattered installation positions of the transmission mechanism. To achieve the effect of high use value, easy disassembly and maintenance, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

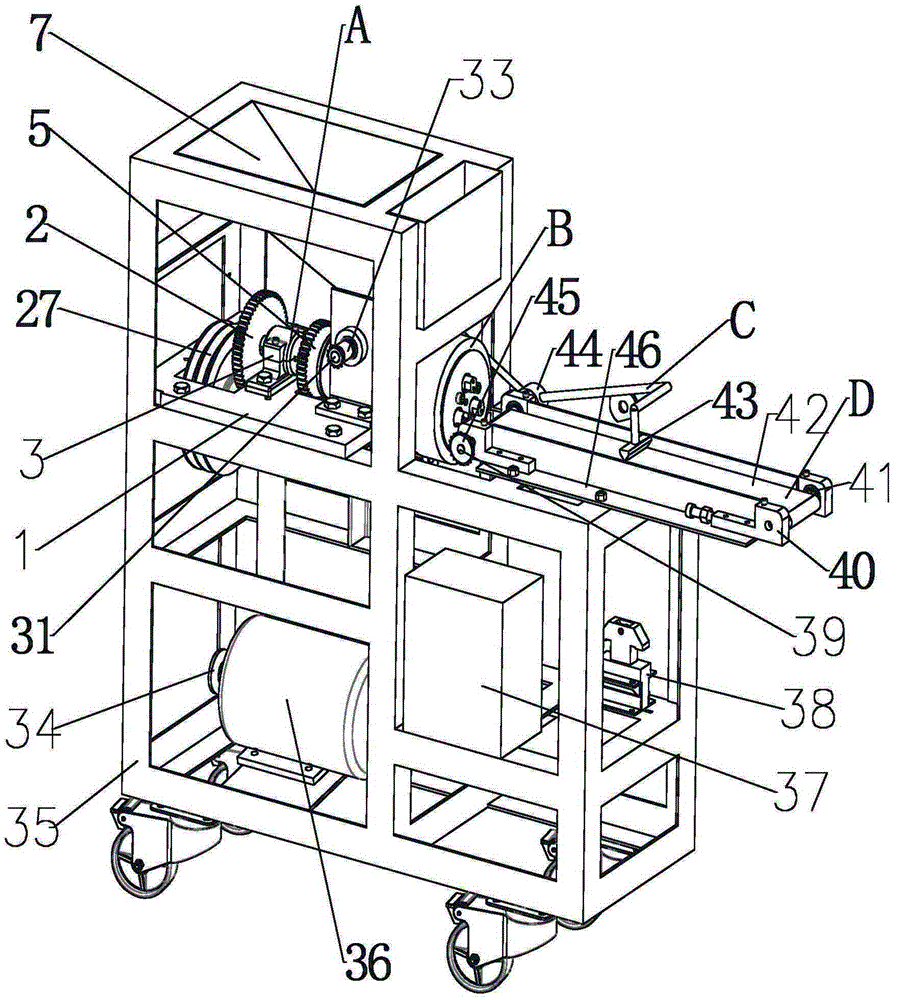

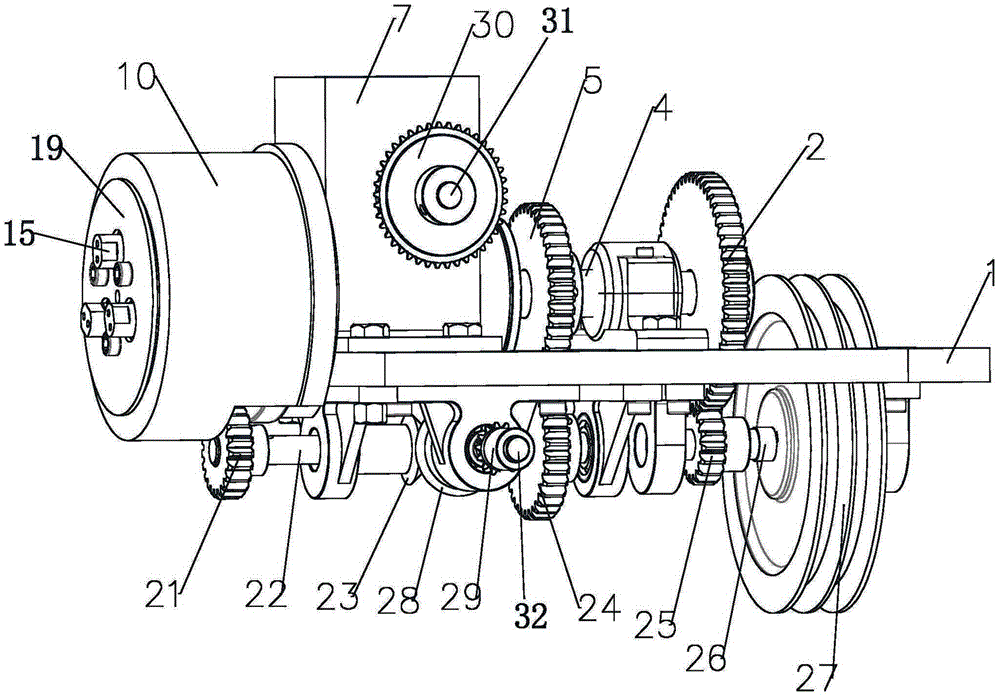

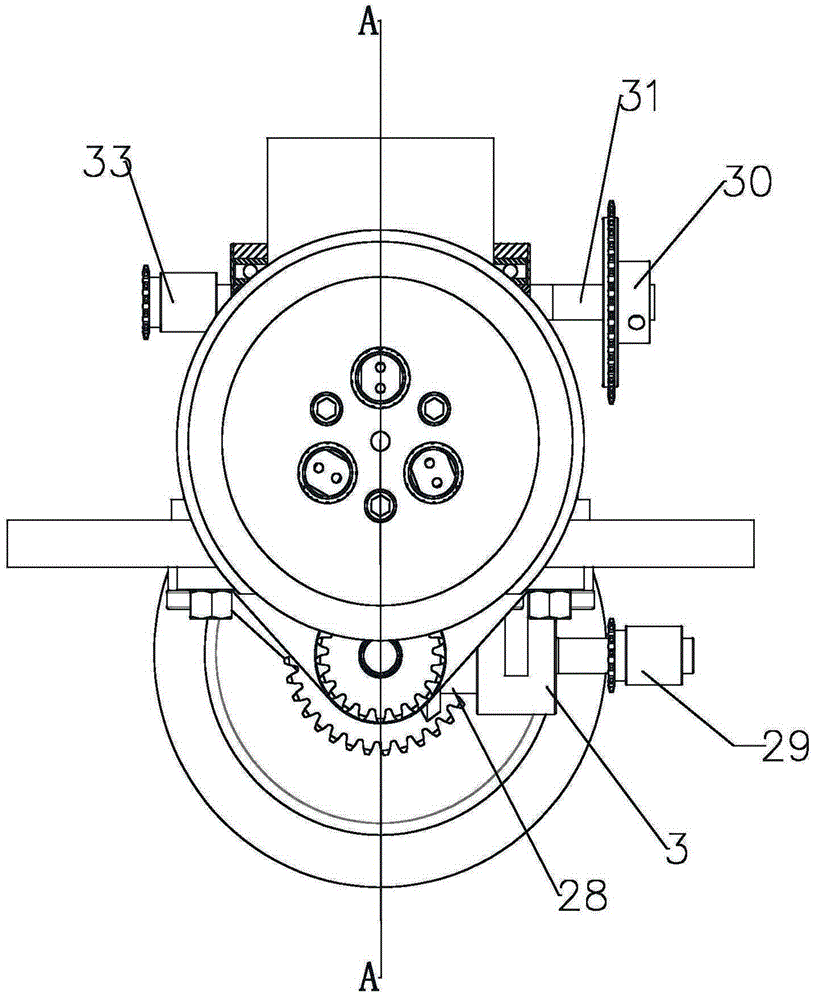

[0022] Attached below Figure 1-4 An embodiment of the present invention is described.

[0023] Yousu fully automatic twist machine has a frame 35, the frame 35 is provided with a forming mechanism and the forming mechanism is fixed in the middle of the frame 35, the forming mechanism includes a transmission mechanism A, a nose device B, a cutting mechanism C And the delivery mechanism D, the transmission mechanism A transmits the power to the head device B and the delivery mechanism D and transports the twist produced from the head device B to the bottom of the cutting head 43 of the cutting mechanism C through the delivery mechanism D The twist is cut off by the cutting head 43; Specifically, the transmission mechanism includes a motor 36, four transmission shafts and a stirring shaft 31, the motor 36 is fixed on the frame 35 and the four transmission shafts are installed on the machine through the bearing housing 3 On the main mounting plate 1 on the frame 35, the transmis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com