Multi-stage material feeding supergravity liquid-liquid reactor apparatus and applications thereof

A technology of liquid-liquid reactor and liquid-liquid reaction, which is applied in the direction of feeding device, chemical method for reacting liquid and liquid, chemical/physical/physical chemical fixed reactor, etc., which can solve complex process, high energy consumption, Problems such as the bulky size of the stepped reactor can achieve the effects of small device volume, increased product yield, and reduced material consumption and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

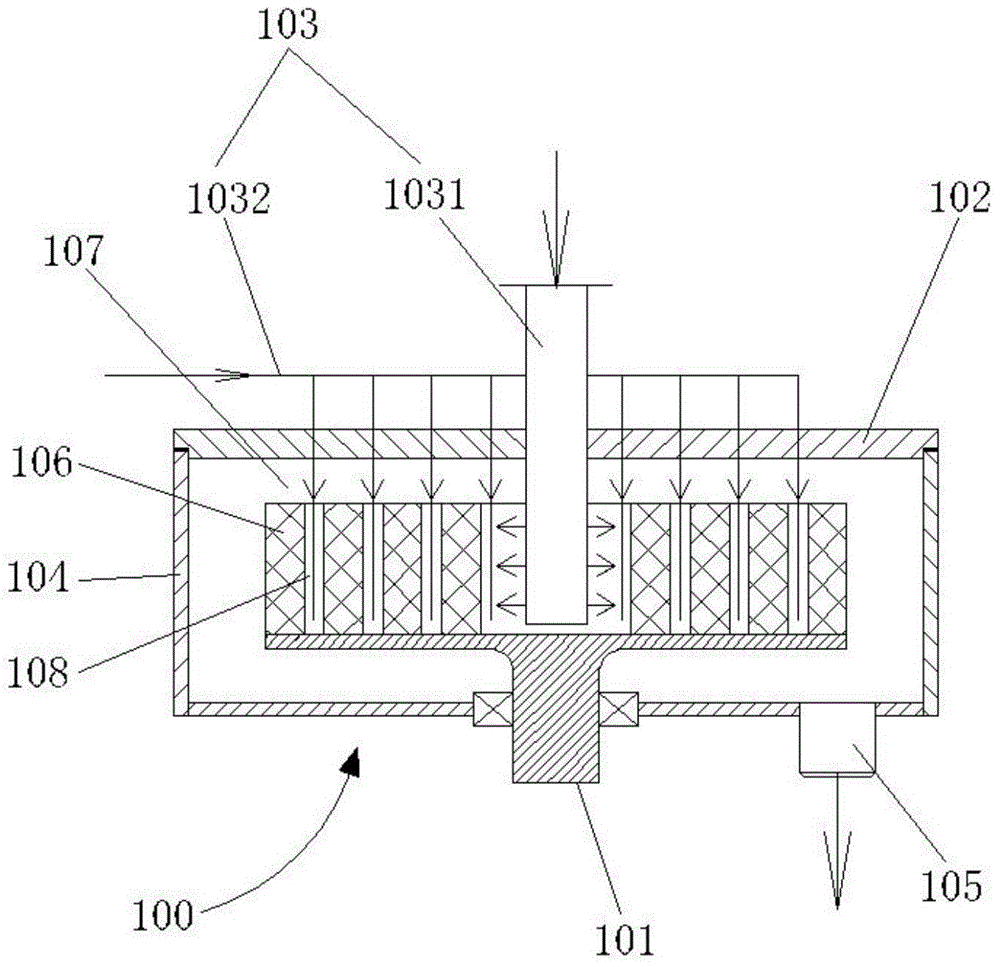

[0033] See figure 1 As shown, a multi-stage feed supergravity liquid-liquid reactor device 100 includes a rotor 101, a housing upper cover 102, a liquid distributor 103 and a housing 104; the lower end of the housing 104 is provided with a liquid outlet 105; The liquid distributor 103 includes an inner liquid distributor 1031 and an outer liquid distributor 1032;

[0034] The rotor 101 is provided with concentric packing rings 106 with different diameters, which are built in the housing 104;

[0035] A gap 107 is provided between the packing ring 106 and the housing upper cover 102, and the gap between the concentric packing rings 106 of different diameters and the housing upper cover 102 is connected, that is, the top of each packing ring 106 is connected to No sealing device is needed between the upper cover 102 of the housing;

[0036] The inner liquid distributor 1031 extends to the middle of the rotor 101 and can spray liquid from the inside to the outside;

[0037] The outer li...

Embodiment 2

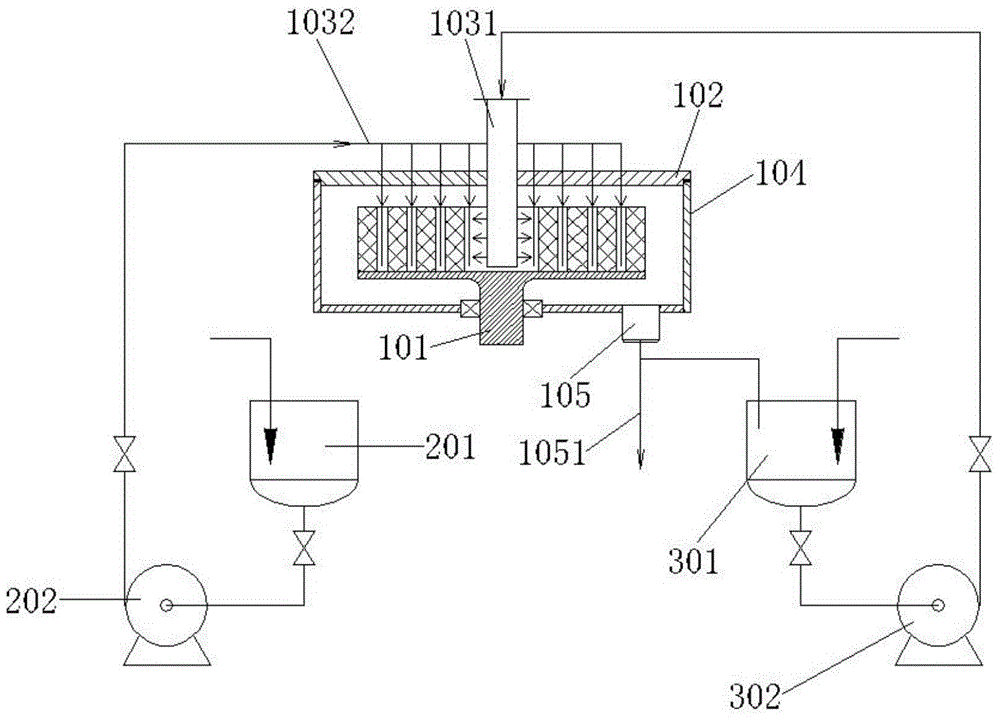

[0043] See figure 2 Shown is a liquid-liquid reaction system device comprising a multi-stage feed supergravity liquid-liquid reactor device of the present invention, wherein the first raw material tank 201 is connected to the first feed pump 202 through a pipe, and the first feed pump It is connected to the outer liquid distributor 1032 through a pipe; the second raw material tank 301 is connected to the second feed pump 302 through a pipe, and the second feed pump is connected to the inner liquid distributor 1031 through a pipe; the lower end of the housing 104 The liquid outlet 105 is connected to the outlet pipe 1051; the second raw material tank 301 is connected to the outlet pipe 1051 through the pipe.

Embodiment 3

[0045] See figure 2 As shown, the application of the liquid-liquid reaction system device including the multi-stage feed supergravity liquid-liquid reactor device of the present invention in the Beckman rearrangement reaction, the specific steps are as follows:

[0046] 1) The raw material cyclohexanone oxime and refrigerant heptane are pumped into the outer liquid distributor 1032 of the multi-stage feed supergravity liquid-liquid reactor device of the present invention through the first feed pump; the specific parameters are: cyclohexanone oxime The volume ratio to refrigerant heptane is 1:13, totaling 18L;

[0047] 2) The raw material amidation liquid is pumped into the inner liquid distributor 1031 of the multi-stage feed supergravity liquid-liquid reactor device of the present invention through the second feed pump; the specific parameters are: the amidation liquid and the first feed pump pump The volume ratio of the mixed liquid is 0.9:1;

[0048] 3) Adjust the rotor speed t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com