Slicing device of solar backplane film

A technology of solar backplane film and slicing device, which is applied in metal processing and other directions, can solve the problems of distance adjustment between cutter and back film, low work efficiency, and no support for back film, and achieve the effects of smooth cut, cost saving and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

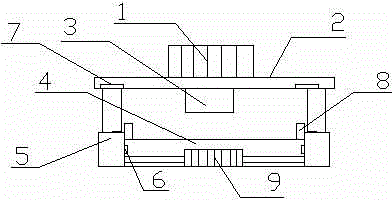

[0011] like figure 1 It is a schematic diagram of the structure of the slicing device for the solar backplane film. The slicing device for the solar backplane film includes a motor 1, a guide rail 2 and a knife holder 3. The guide rail 2 is provided with a knife holder 3, and both sides of the cutting platform 4 are fixed with the hydraulic rod 5. Connection, the top of the hydraulic rod 5 is fixedly connected with the guide rail 2, the two sides of the cutting platform 4 are fixedly connected with the hydraulic rod 5 through the bolt 6, the top of the hydraulic rod 5 is fixedly connected with the guide rail 2 by placing it in the slot 7 of the guide rail 2, and the hydraulic pressure The rod 5 is connected with the control motor 9 and the two ends of the cutting platform 4 are provided with stoppers 8 .

[0012] First, the hydraulic rod 5 is raised by starting the control motor 9, and the hydraulic rod 5 will drive the guide rail 2 to draw a certain distance from the cutting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com