A three-dimensional undulating surface vitrified brick forming device

A molding device and surface vitrified tile technology, applied in ceramic molding machines, manufacturing tools, etc., can solve the problems of limited use occasions, low wear resistance, etc., and achieve the effects of good decoration and good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

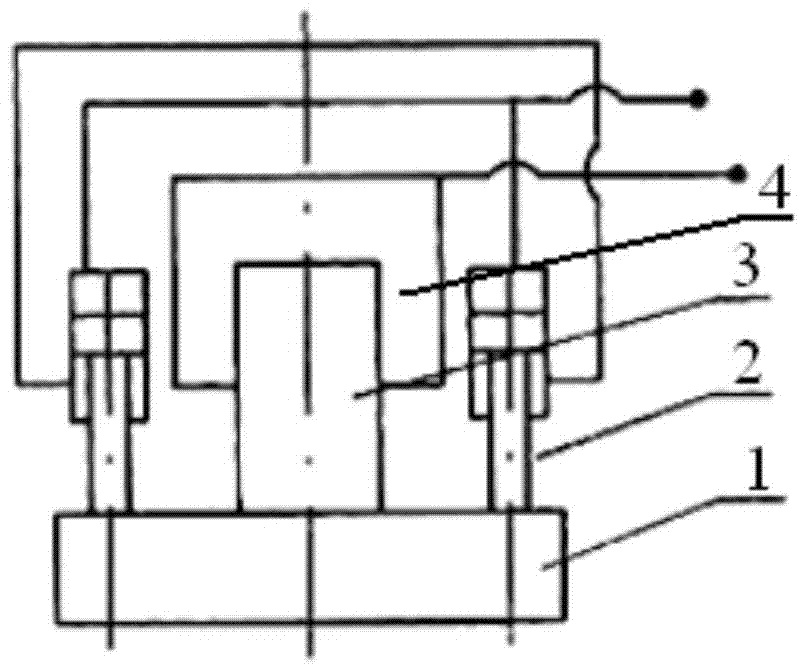

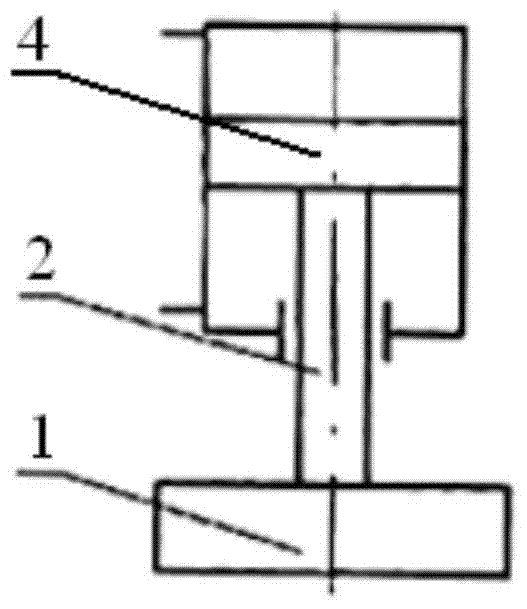

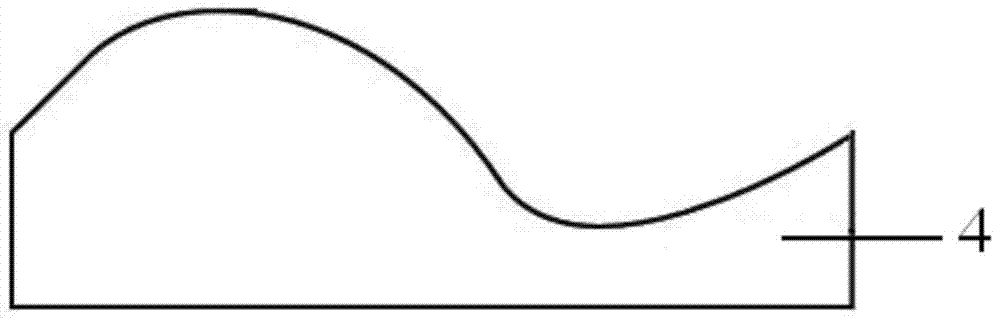

[0025] A three-dimensional undulating surface vitrified brick forming device, its structure is as follows Figure 1-2 As shown, it mainly includes movable beam 1, piston 2, plunger 3 and mold 4. Piston 2 and plunger 3 are connected on movable beam 1, and are driven to move up and down by movable beam 1; mold and 4 pistons 2 and plunger 3 are movable connected, driven by the piston 2 and the plunger 3 for compression molding, the structure of the mold 4 is as follows image 3 As shown, the inner surface is an undulating concave-convex surface, and the undulation height of the concave-convex surface is greater than 1 mm. In addition, the die opening of the mold 4 is connected to the delivery pipeline for transporting the color glaze powder slurry or powder, and the pipe mouth of the pipeline is connected to the die opening to be provided with a predetermined pattern, and the color glaze powder slurry or powder is injected into the mold through the die opening to form a predeterm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com