Patents

Literature

44results about How to "Strong flatness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production method of nano crystal-sand floor

ActiveCN101337366AStrong hardnessAnti-wear strengthPolishing machinesPretreated surfacesFloor slabWear resistant

The invention discloses a method for producing nanometer crystal sand surface floor slabs. The production method comprises the steps of slicing timber, selecting slabs and grooving according to conventional techniques, and further comprises the steps of conducting the polishing treatment for floor slab base materials, including seventeen-layer multiple permeation paint application technique, that is, applying two layers of water environmental protection primer, three layers of wear-resistant primer, nine layers of elastic primer, and three layers scraping-resistant finishing coat. The production method adopts the seventeen-layer multiple mutual-type permeation technique, that is, three plus two plus nine plus three, and utilizes the interactive permeation technique of nano-titanium paint molecules, so as to enable paint molecule layers to permeate into wood molecules. Through a plurality of layers of wear-resistant primer and hardening primer, and through leveling and a plurality of curing and sanding layers, the floor slab has high performance of super strong hardness, wear resistance, scraping resistance, oxidation and yellowing resistance. The paint surface adhesive force, the flexibility, and the scraping resistance of the floor slab greatly exceed those of the ordinary technical floor slab.

Owner:浙江永吉木业有限公司

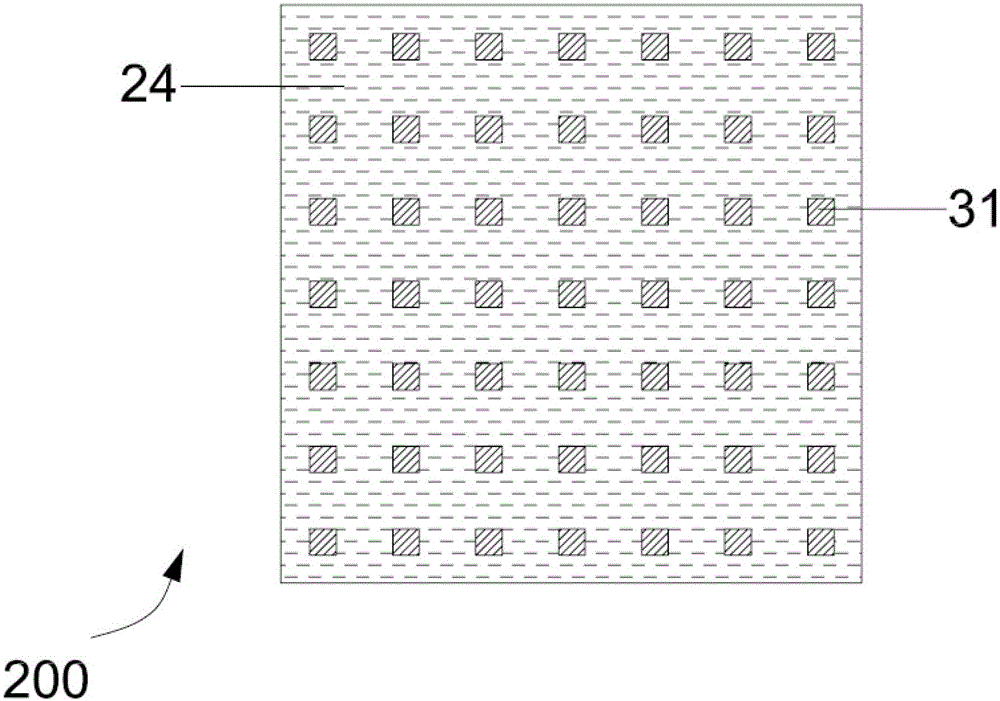

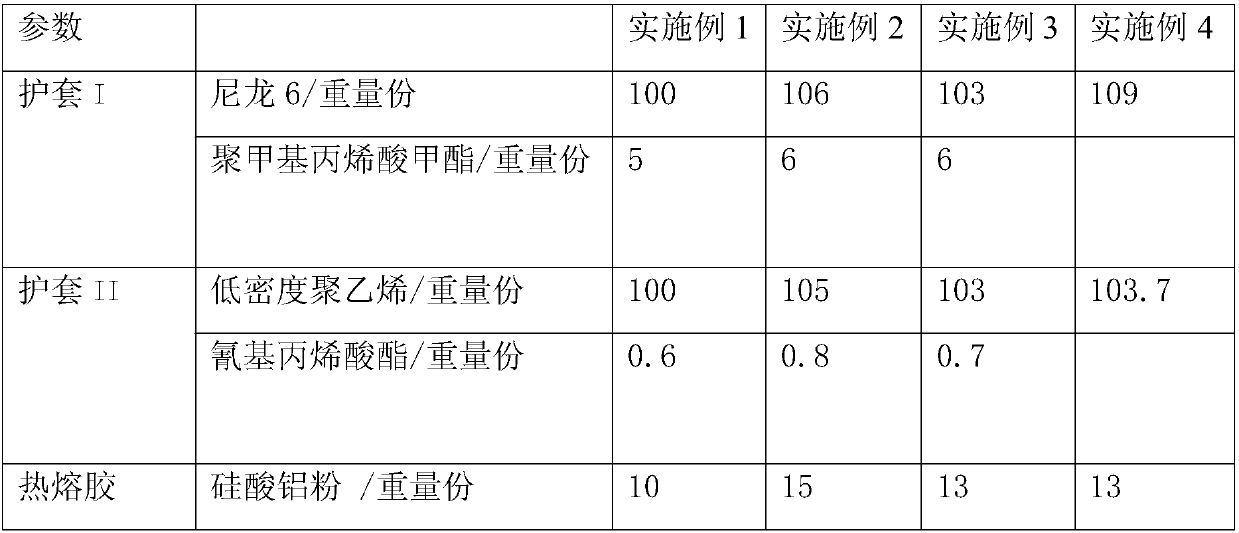

Method for producing super-form-stable lining cloth

ActiveCN104432788AImprove flatnessStrong flatnessLiquid surface applicatorsFabric breaking/softeningEngineeringHot-melt adhesive

The invention discloses a method for producing a super-form-stable lining cloth. The method comprises the steps of desizing loosing processing or desizing scouring and bleaching processing, drying and settling and coating and the like. The two faces of the cloth are coated with hot melt adhesive in a dotted mode, so that adhesive capacity is greatly improved, and the flatness of clothes on adhesive portions and sewing portions is improved. Compared with a common lining cloth, the super-form-stable lining cloth has high adhesive force and super flatness. Compared with a net film, the super-form-stable lining cloth is high in air permeability, good in rebound resilience, good in follow-up capacity and soft in hand feeling, particularly the washed clothes still have the advantages of high flatness and good ironing-free performance, and the requirements for performance diversity and innovation of the manufacturing process and technique of current clothes are met.

Owner:KEDE BAOBAOLING LINING CLOTH NANTONG

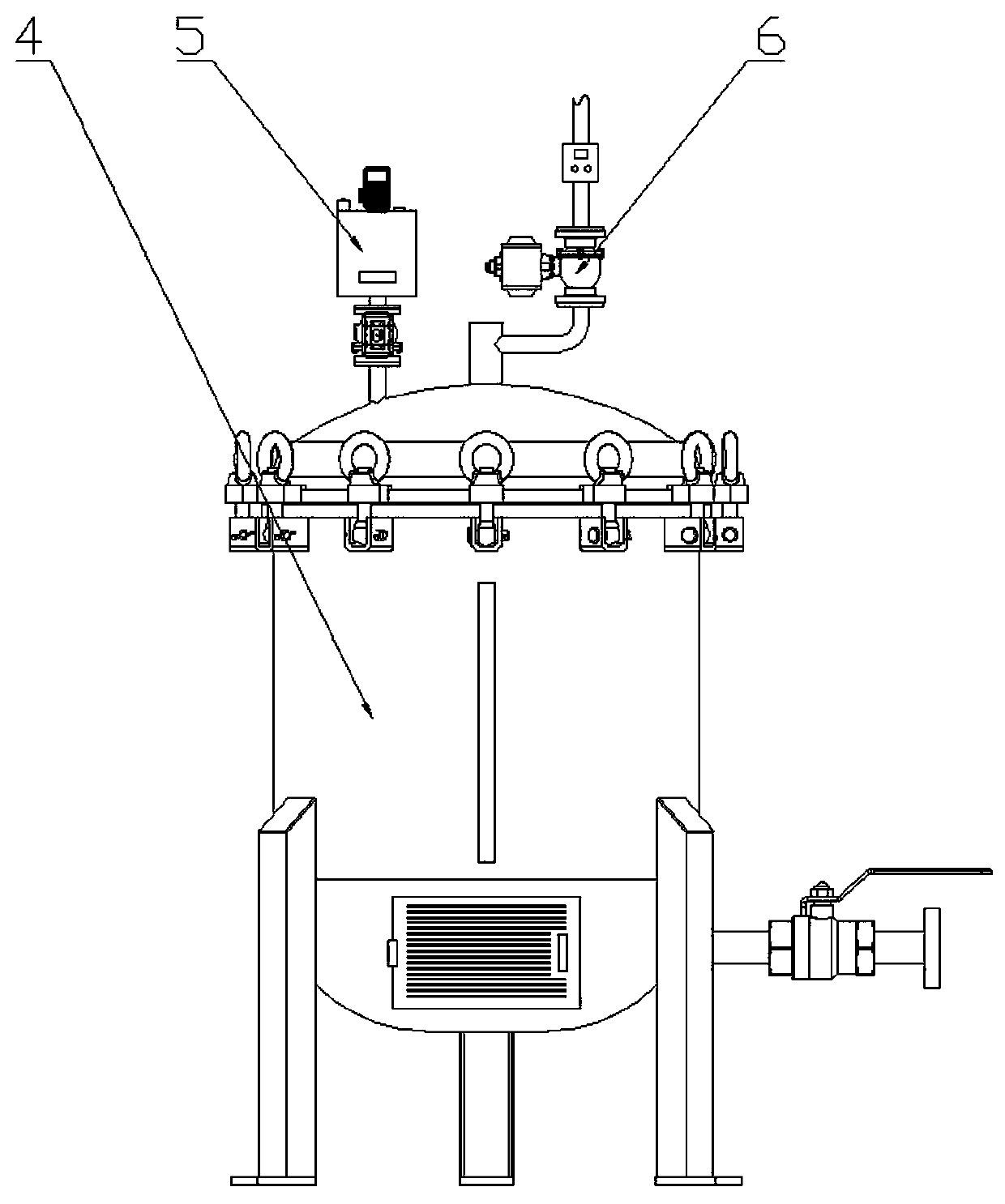

Liquid foaming backfilling material for toilet and preparation method thereof

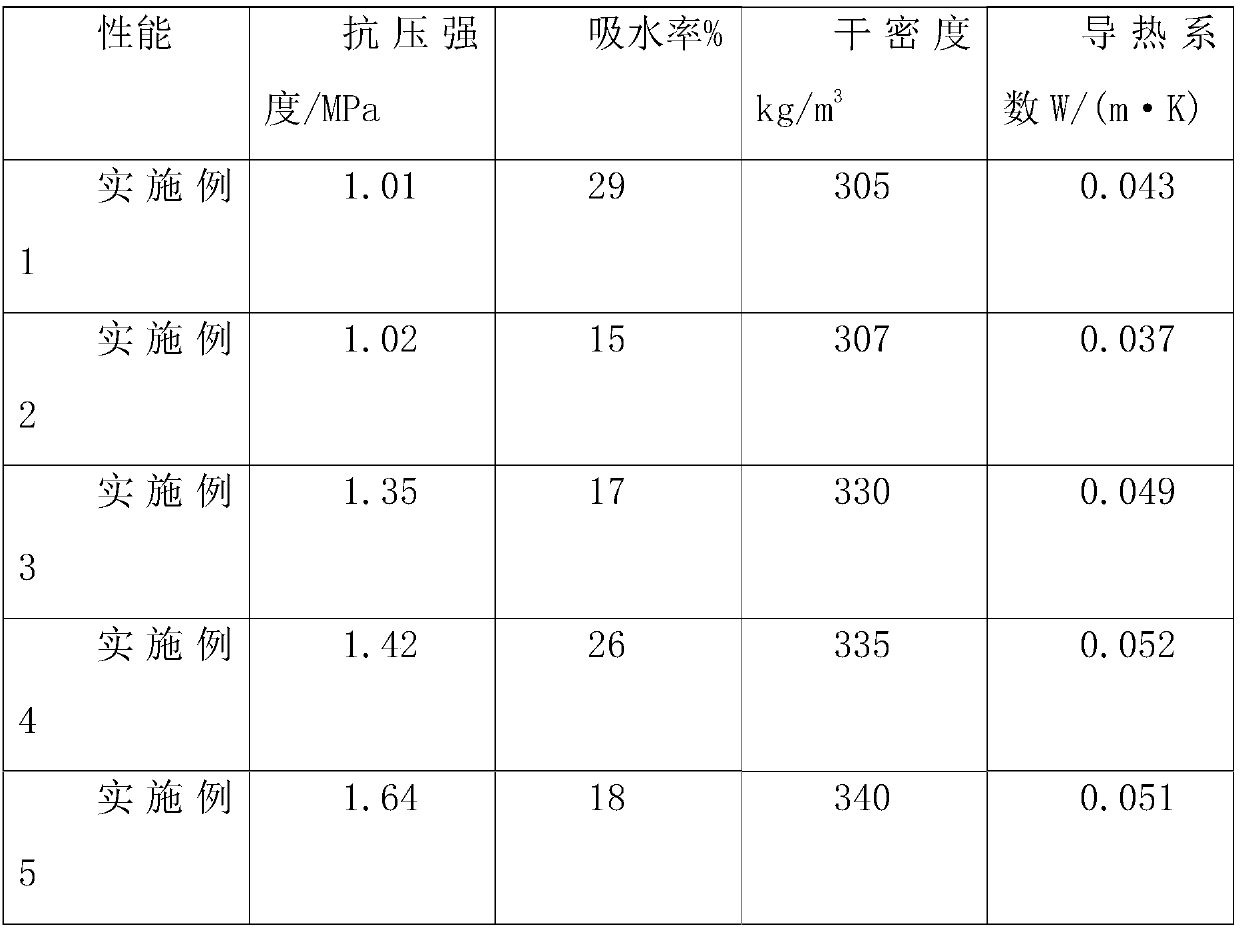

The invention provides a liquid foaming backfilling material for a toilet and a preparation method thereof. The liquid foaming backfilling material is prepared from the following raw materials by weight: 280 to 400 parts of cement, 1 to 3 parts of a liquid foaming auxiliary agent, 2 to 5 parts of calcium formate, 1 to 5 parts of a water repellent, 1 to 2 parts of a water-retaining agent, 0.8 to 1.2 parts of crack-resistant fiber, 0.8 to 2 parts of a thickening agent and 200 to 240 parts of water, wherein the foaming auxiliary agent is at least one selected from the group consisting of an animal cement foaming agent and a plant cement foaming agent. The liquid foaming backfilling material provided by the invention solves the problem of complicated backfilling construction for the toilet dueto factors like a site. The liquid foaming backfilling material prepared by using the method provided by the invention has a bulk density of about 300 to 340 kg / m3, has good degree of flowing in backfilling construction, is tightly bonded with the wall body part of the to-be-backfilled area of the toilet, and has good overall flatness. The liquid foaming backfilling material has a hardening timeof 24 h in summer and about 48 h in winter, and has the advantages of no cracking, no shrinkage, good strength and leakage resistance after hardened. The liquid foaming backfilling material prepared by using the method provided by the invention has a hardening strength of more than 1 MPa and a water absorption rate of less than 30% after 7 days, meets the water absorption performance of 2 to 4 (v / v%), and has good waterproofness.

Owner:重庆老顽固实业有限公司

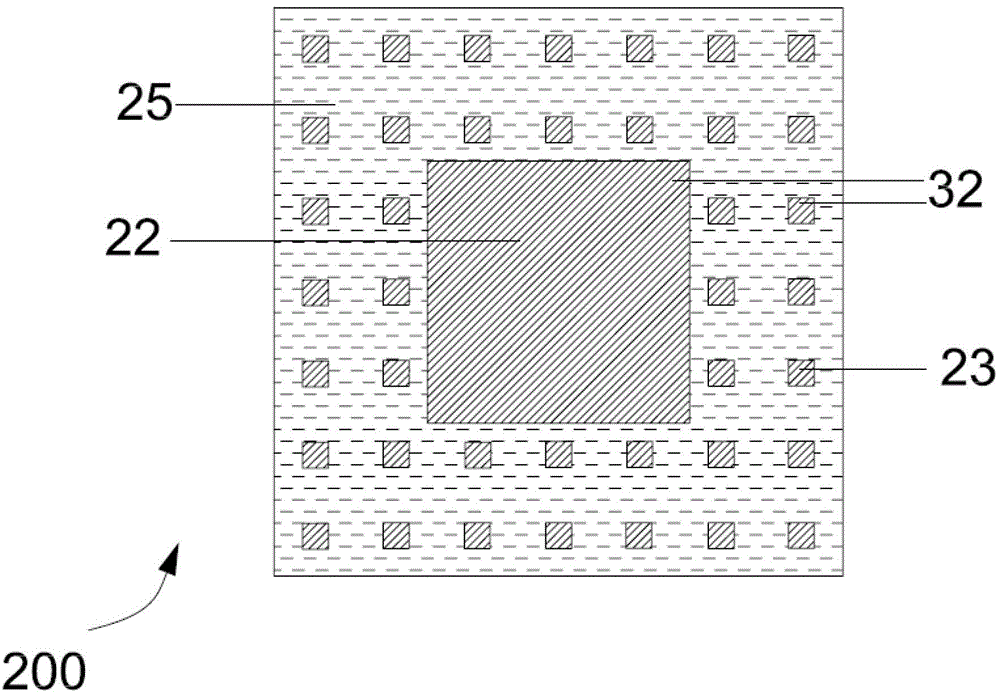

Manufacturing method for rewiring quad flat no-lead (QFN) packaging component

InactiveCN103065975ASmall sizeImprove yieldSolid-state devicesSemiconductor/solid-state device manufacturingScreen printingChemical plating

The invention discloses a manufacturing method for a rewiring quad flat no-lead (QFN) packaging component. A chip carrier and lead feet of the manufactured rewiring QFN packaging component are formed by using of an etching method in the process of packaging technology. Insulating filling materials are arranged between the chip carrier and the lead feet, and in grooves between the lead feet by using an injection molding method or a silk-screen printing method. Rewiring layers are manufactured by using of electroplating and chemical plating methods and are packaged by using of plastic package materials. After the process of plastic package, an independent chip carrier and independent lead feet are formed by using of the etching method or a mechanical grinding method. The manufactured rewiring QFN packaging component is high in input / output (I / O) density, low in manufacturing cost and good in reliability.

Owner:BEIJING UNIV OF TECH

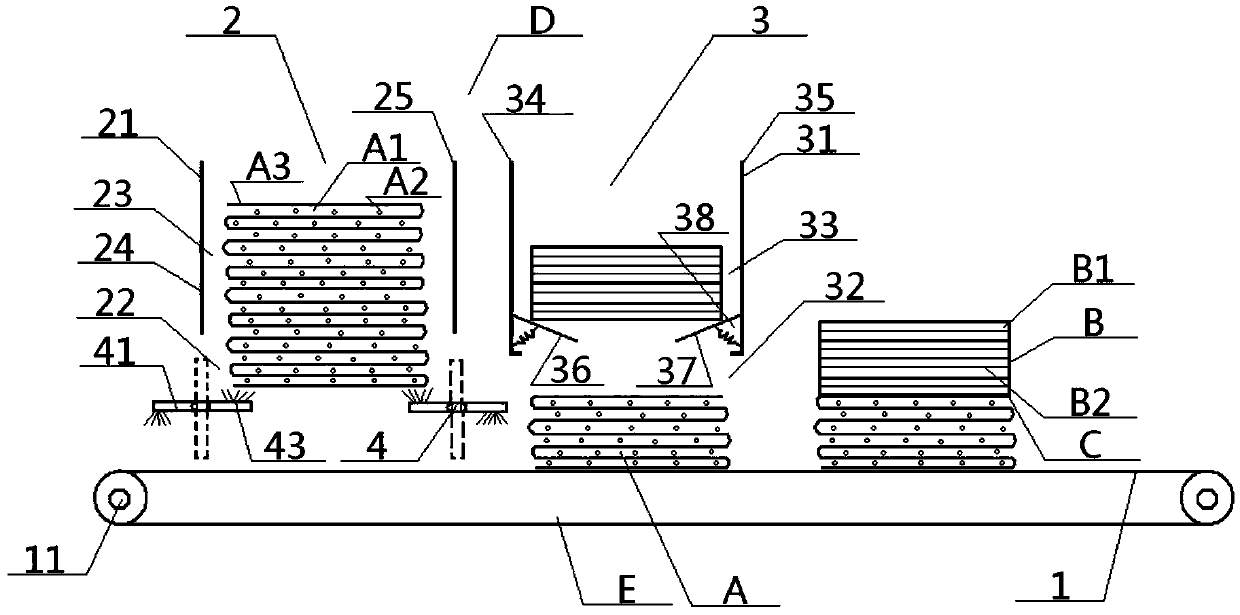

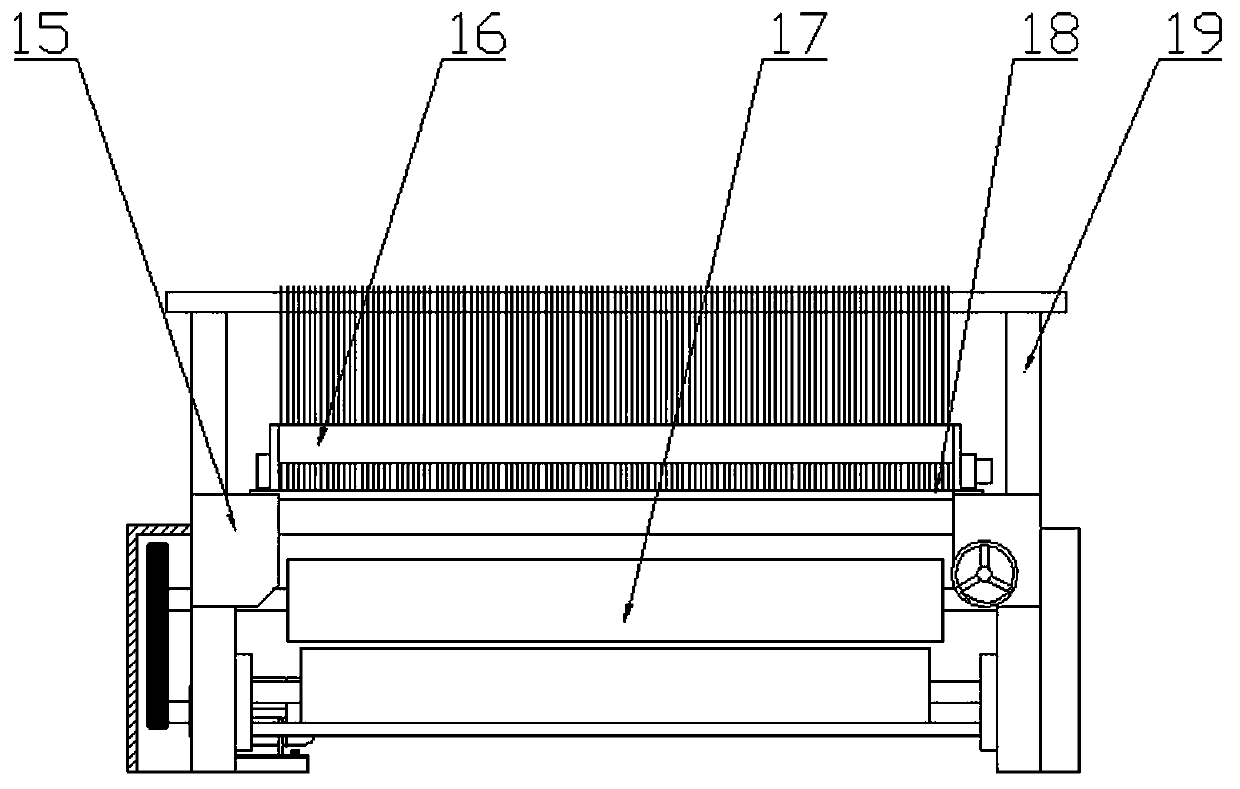

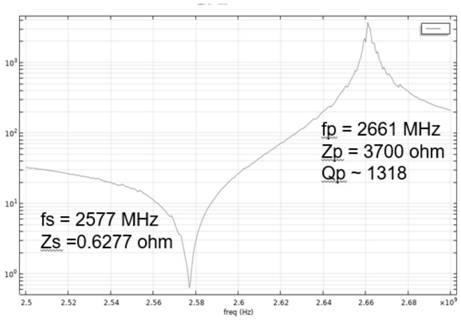

Automatic troweling machine

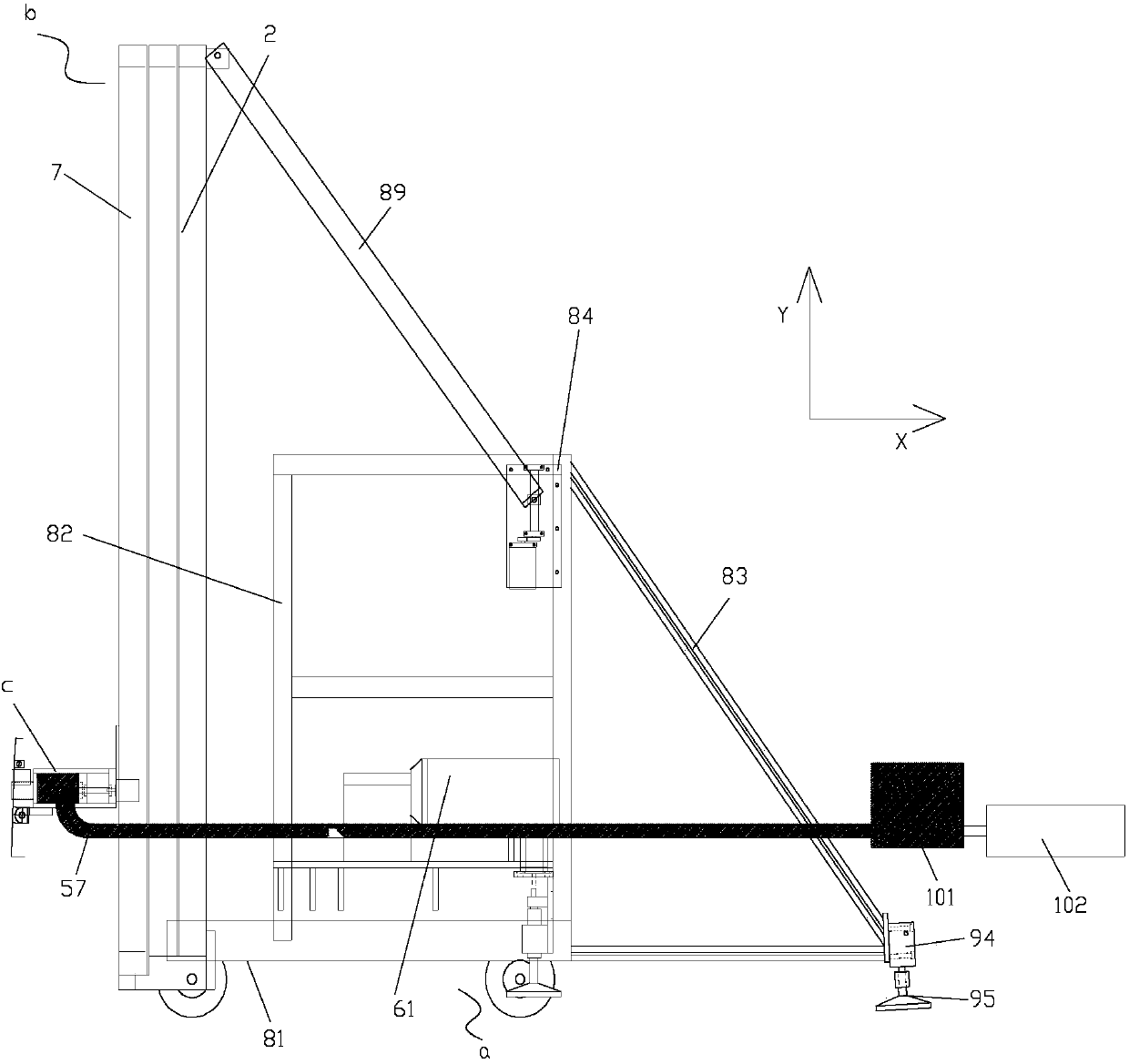

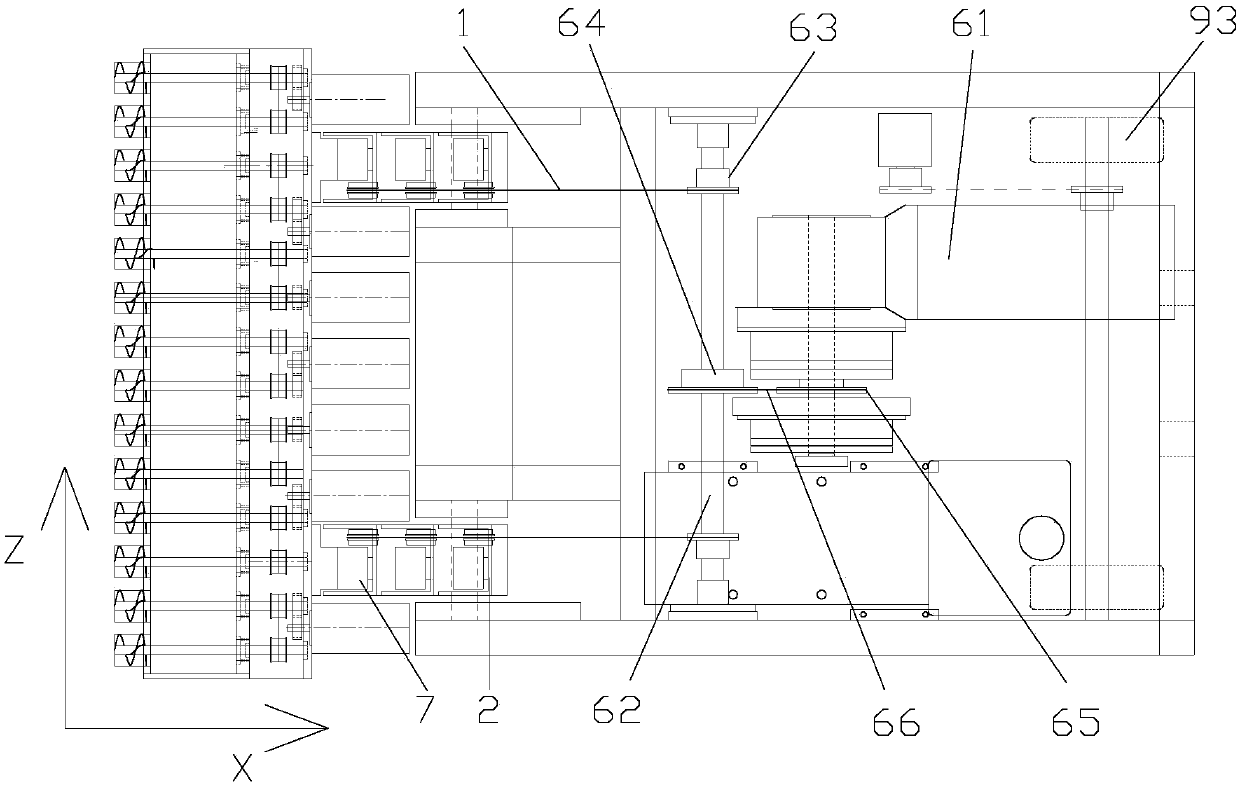

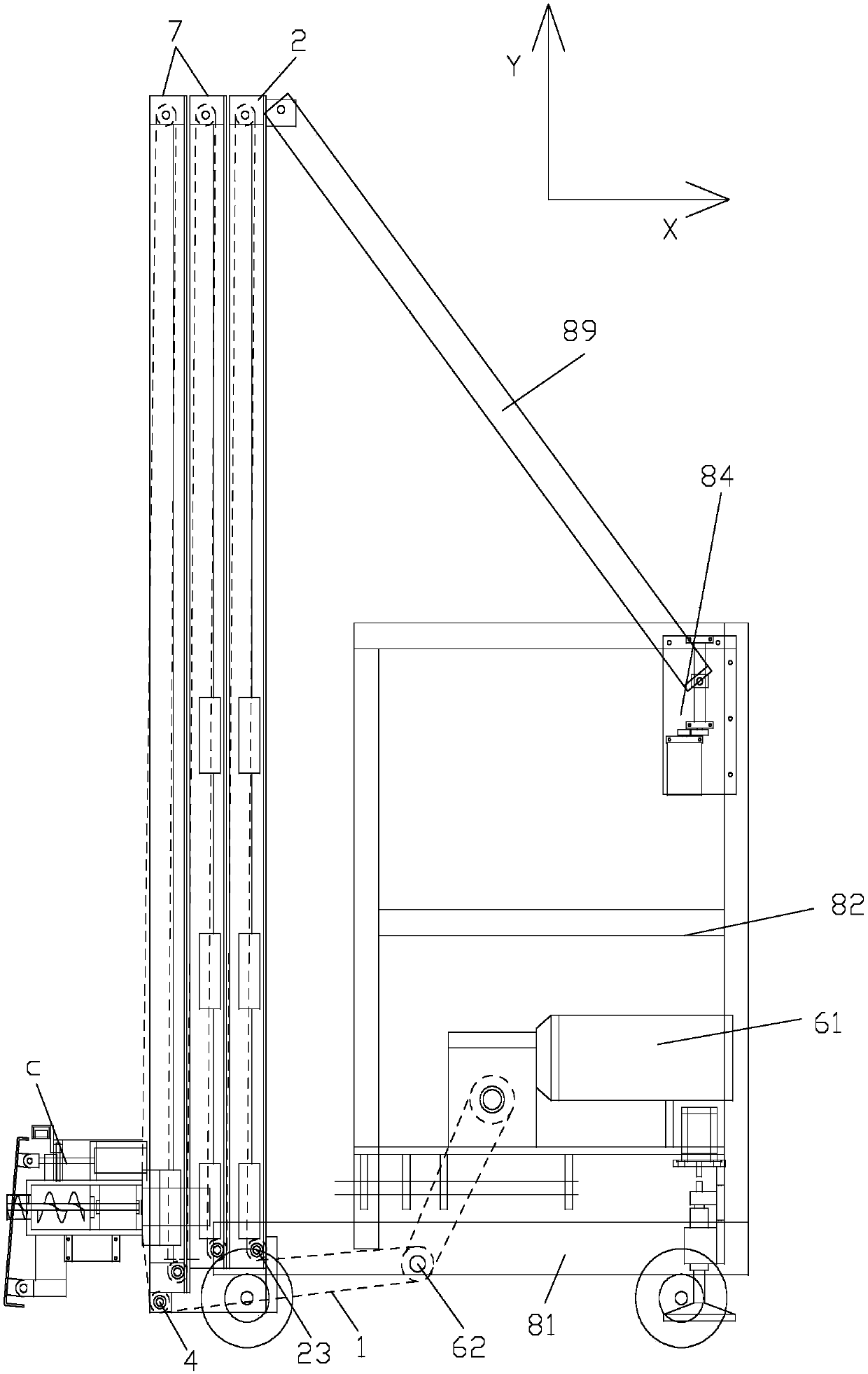

PendingCN107893522ASufficient supplyGuaranteed flatnessTransportation and packagingRotary stirring mixersAutomotive engineeringTraction drive

The invention relates to the technical field of constructional engineering machinery, in particular to an automatic troweling machine. The automatic troweling machine comprises a walking machine seatassembly, a traction lifting assembly and a discharging machine head assembly. The traction lifting assembly comprises a lifting stand column device and a traction driving device, and the lifting stand column device comprises a traction driving belt, a supporting stand column and a lifting stand column set; and the discharging machine head assembly comprises a slurry stock bin with the front surface being provided with a discharging pipe, a spiral material conveying device installed in the slurry stock bin and a troweling plate installed on the front surface side of the slurry stock bin, a discharging port is formed in the troweling plate, a pressure sensor used for conducting pressure detection is further installed at the position, corresponding to the discharging port, of the troweling plate, and a slurry conveying hose is further installed on the slurry stock bin. According to the automatic troweling machine, the structure is simple, moving is flexible, material supplying is precise, adjustability is high, the operating efficiency is high, the operating range is wide, the flatness of wall surface troweling is high, and the automatic troweling machine has high practical value andmarket promotion value.

Owner:深圳市森博机器人有限公司

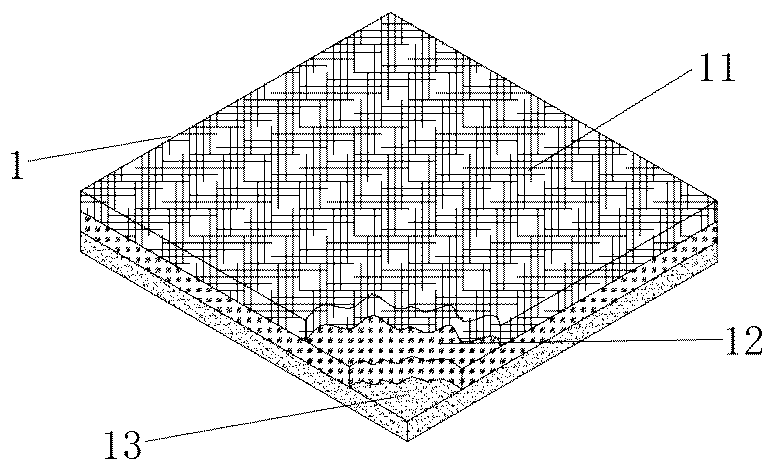

Ultra-weather resistant building outer wall paint film wall cloth and manufacturing process thereof

The invention relates to an ultra-weather resistant building outer wall paint film wall cloth and a manufacturing process thereof. The paint film wall cloth provided by the invention comprises a paint film colored sheet layer and a base material layer which are integrally formed, wherein the paint film colored sheet layer is formed by coating the two surfaces of a glass fiber cloth with color paste, drying the glass fiber cloth, and grinding the glass fiber cloth; the color paste is prepared by mixing a natural mineral pigment, and an elastic emulsion type glue solution or fluorocarbon coating according to certain parts by weight; the base material layer is formed by coating the two surfaces of a fiberglass-polyester mixed surface felt with thick plasma type emulsion, and drying the fiberglass-polyester mixed surface felt. According to the ultra-weather resistant building outer wall paint film wall cloth provided by the invention, the defects that difficulty in paint coating, uneven thickness after coating, easiness in loosening, sand falling and the like of the traditional granite paint are overcome; a paint film colored sheet and a base material are integrally formed through hot pressing, the thickness of the paint film colored sheet layer on the base material layer is strictly controlled in a manufacturing process, a vacuum step is strictly controlled, and an UV (ultraviolet) machine is used for glazing to seal and cure, so that the decorating wall cloth provided by the invention is high in uniformity, flatness, anti-water ability, antioxidant ability and ultraviolet resistance. The blank of outer wall decorating wall cloth in the market is filled.

Owner:刘新宇

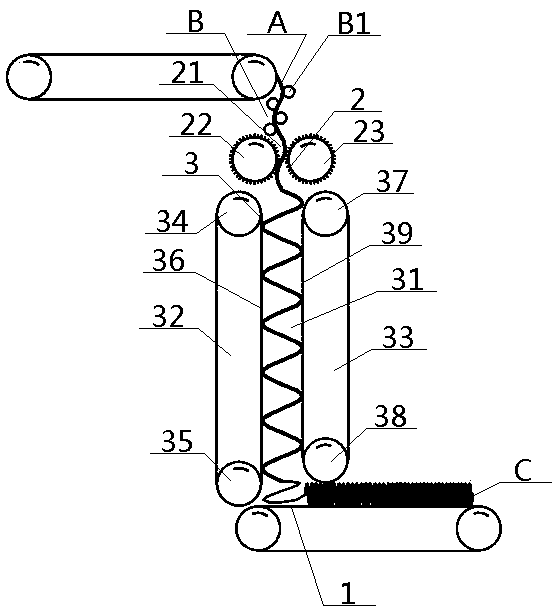

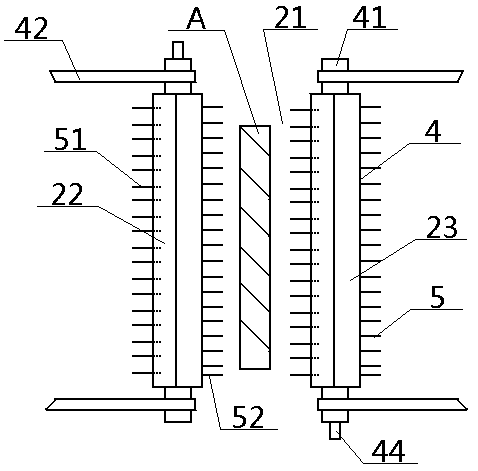

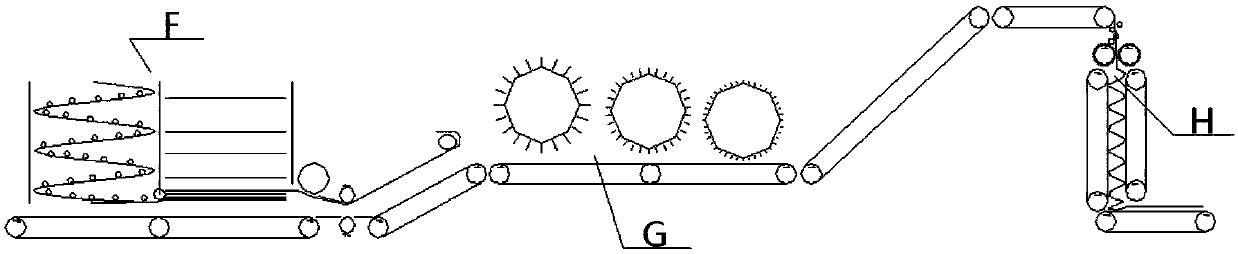

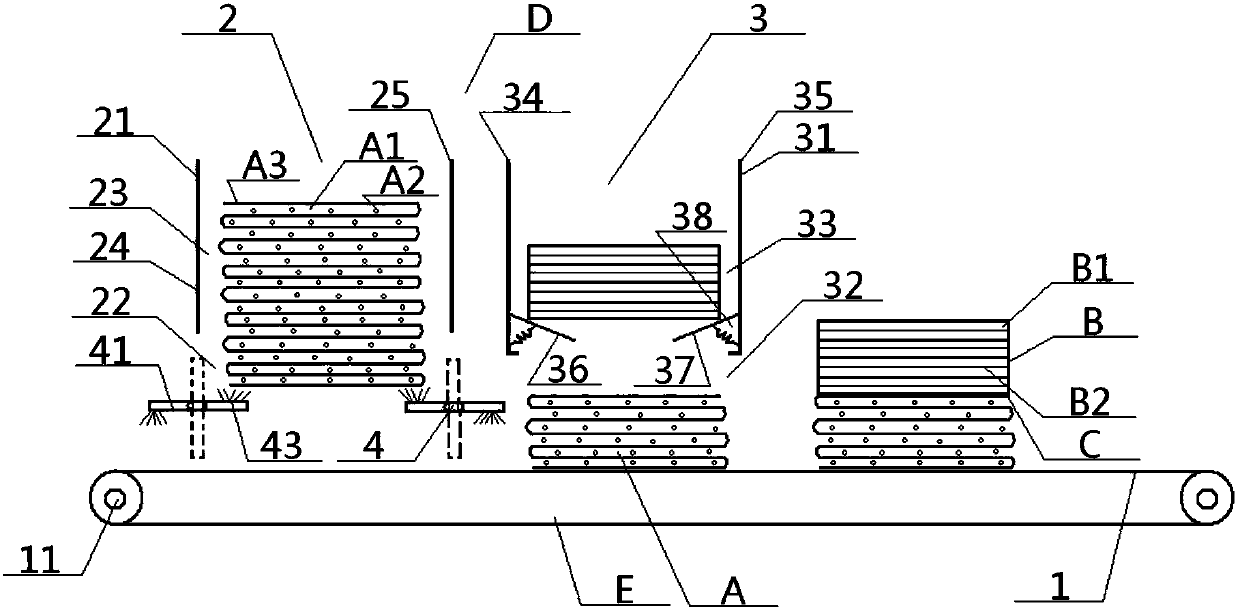

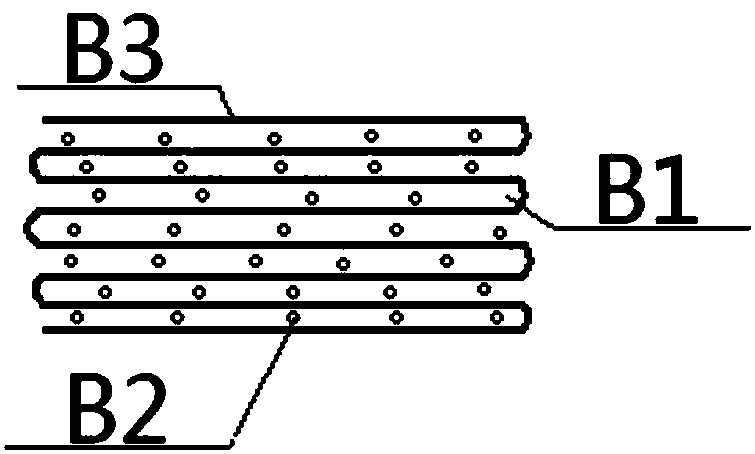

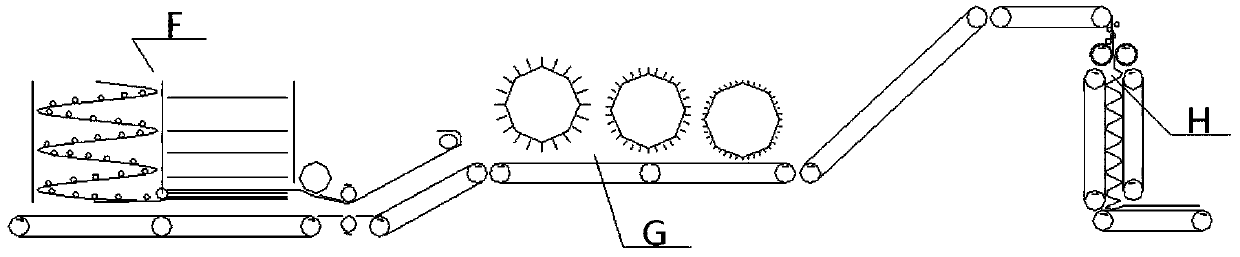

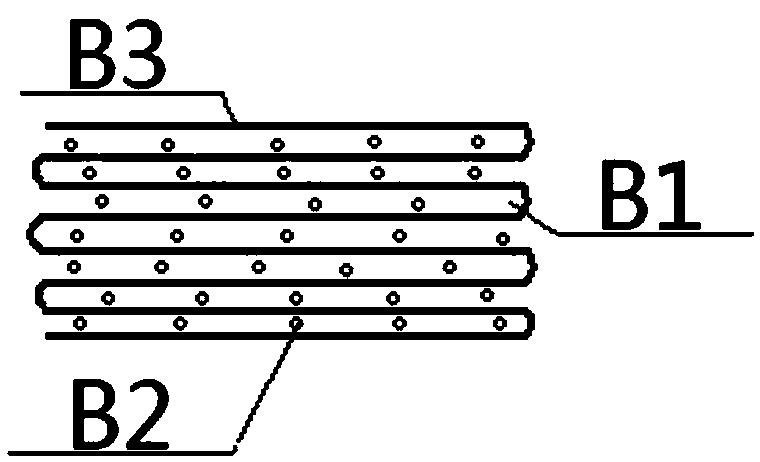

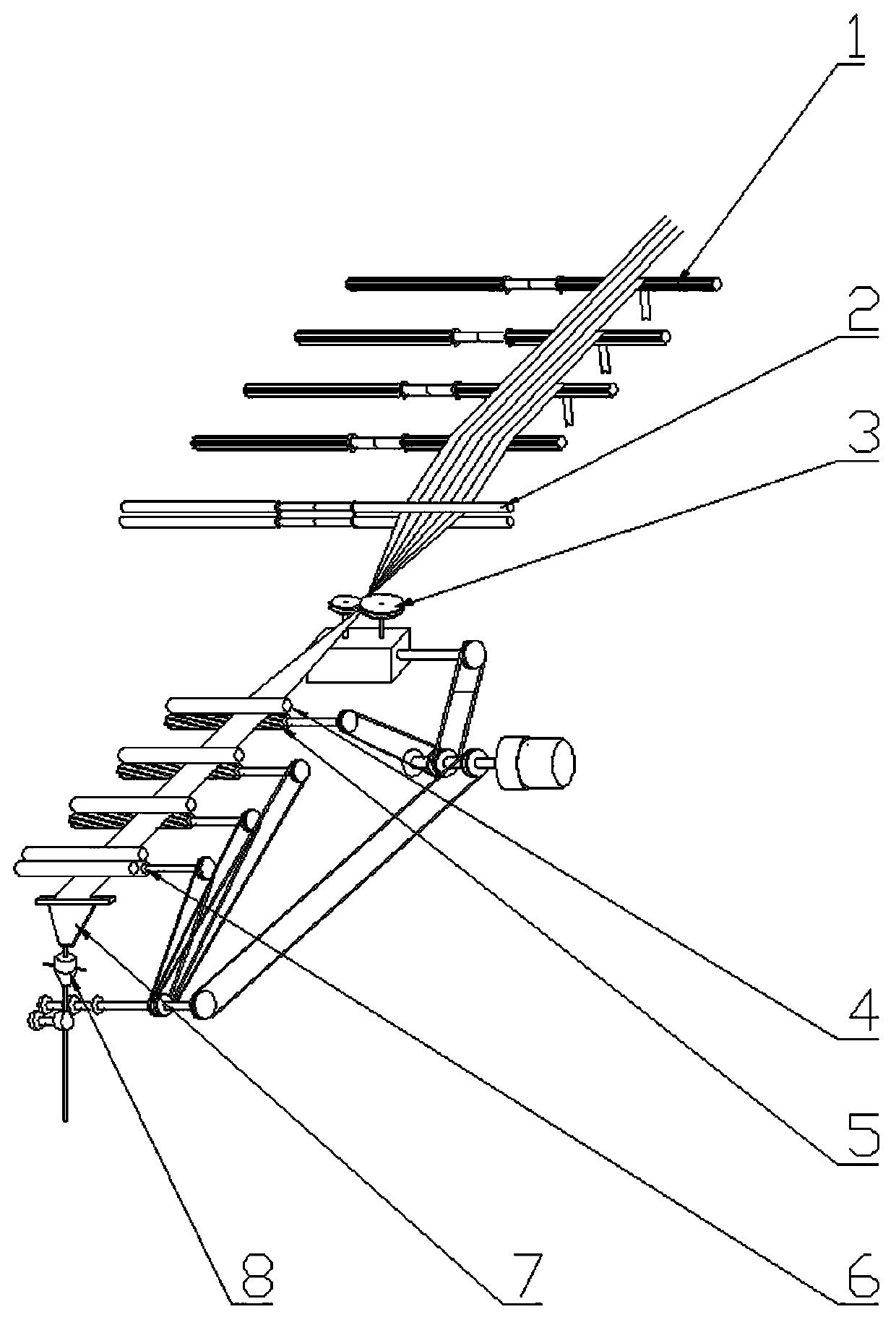

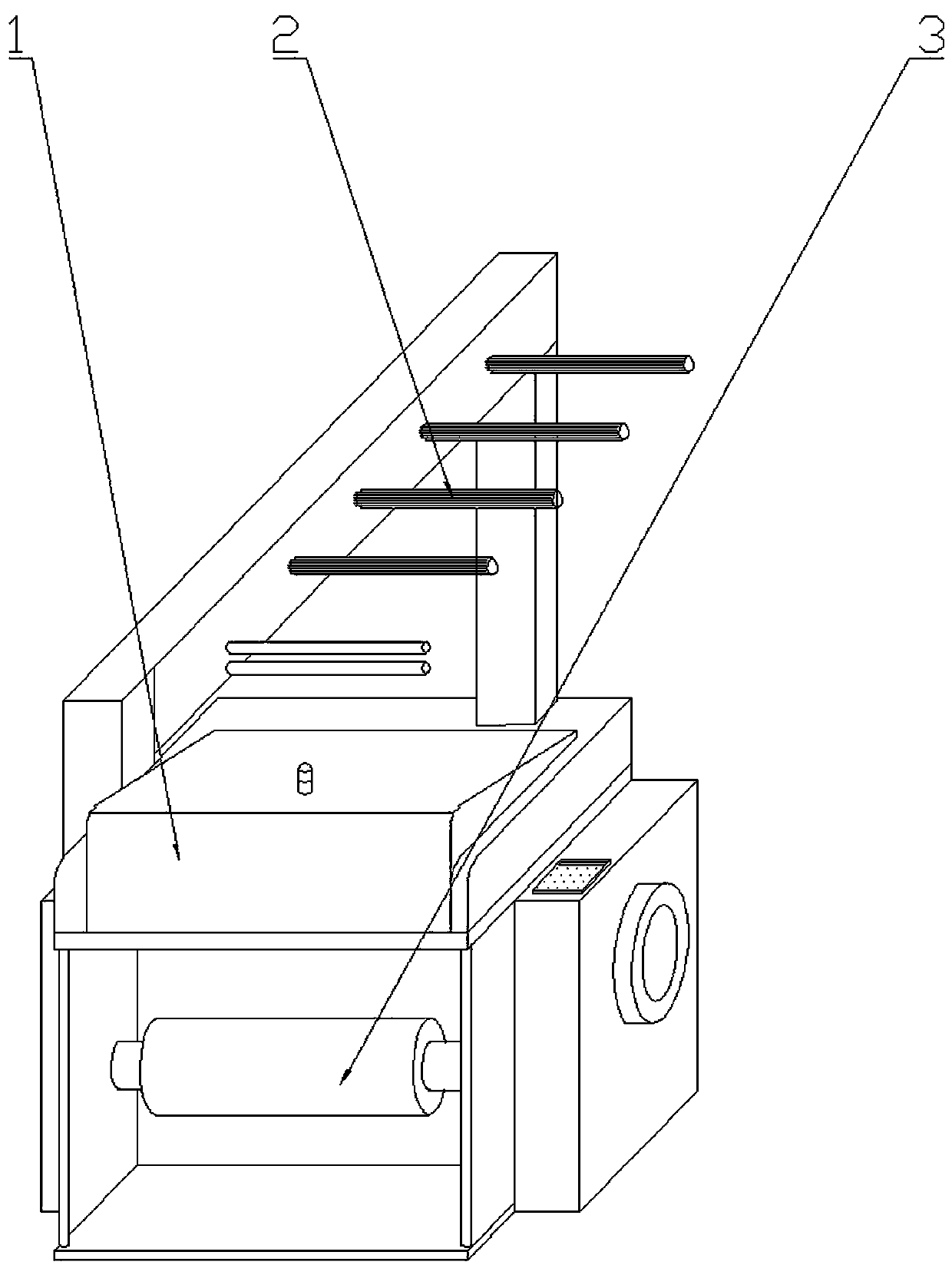

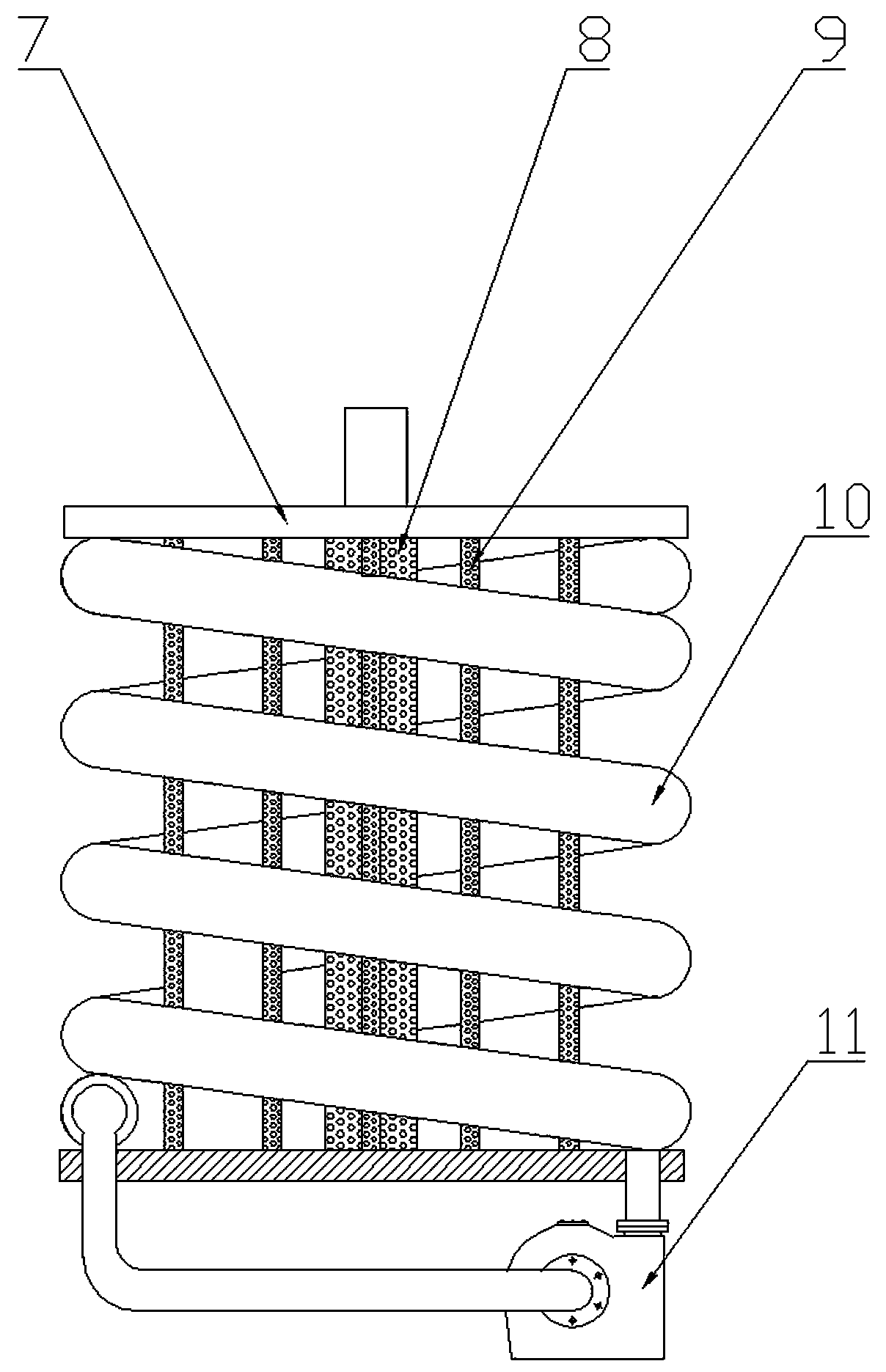

Vertical net laying system for honeycomb porous structure cotton and using method thereof

The invention discloses a vertical net laying system for honeycomb porous structure cotton. A top inlet of a cotton supply channel is communicated with a filament introduction region, forward and reverse filaments introduced in the filament introduction region are perpendicular to weaving bodies passing through the cotton supply channel, a bottom outlet of the cotton supply channel is communicatedwith the top face of a horizontal conveyor belt under the channel through a cotton discharge channel, left and right reciprocating rollers at the two sides of the cotton supply channel include reciprocating roller bodies and multiple reciprocating needles arranged on the roller bodies, the reciprocating needles can include breathable needles so as to be communicated with roller inner cavities inside the reciprocating roller bodies, and left and right cotton discharging portions on the two sides of the cotton discharge channel are each composed of multiple needle rollers sequentially distributed from top to bottom. Due to the design, the weaving and crossing effect is high, the internal structure of weaving bodies can be changed, the functionality is high, the weaving bodies of the porousstructure are formed, the arranging effect on the interiors and exteriors of the weaving bodies is high, and the structure uniformity and surface flatness of the weaving bodies can be improved.

Owner:平邑经发科技服务有限公司

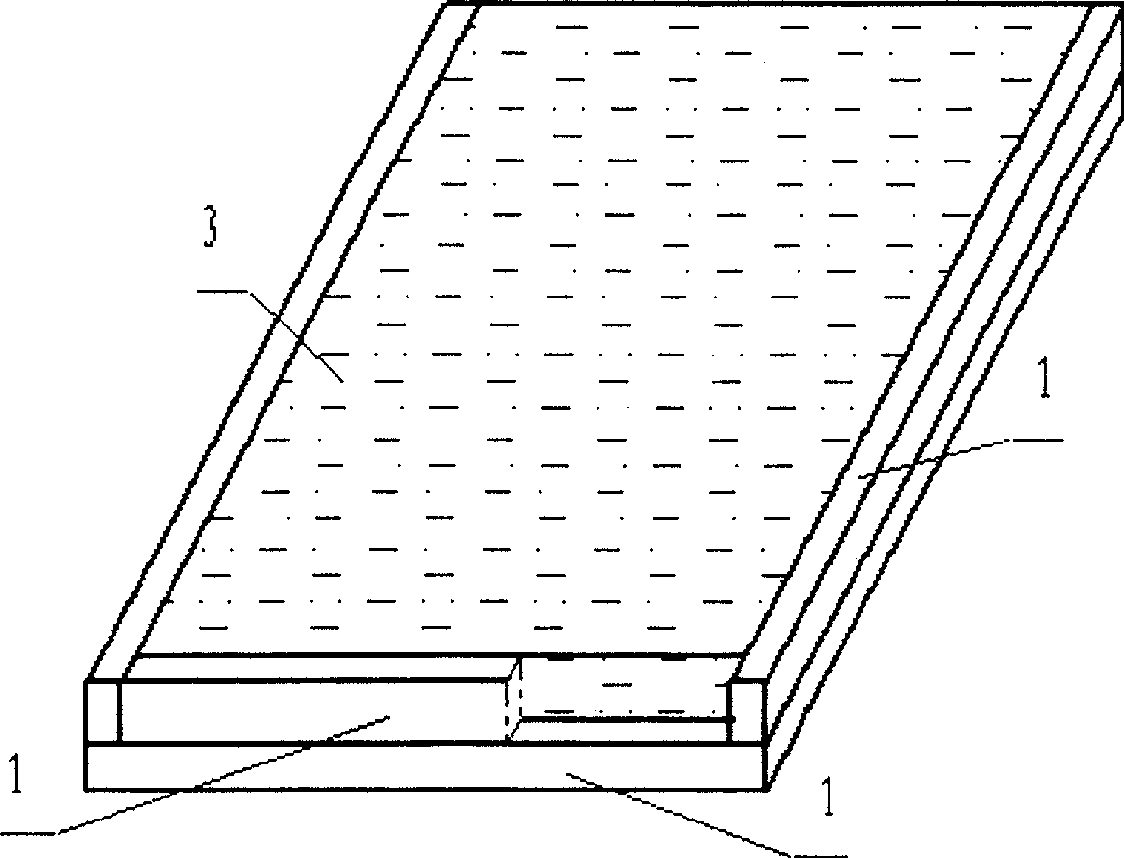

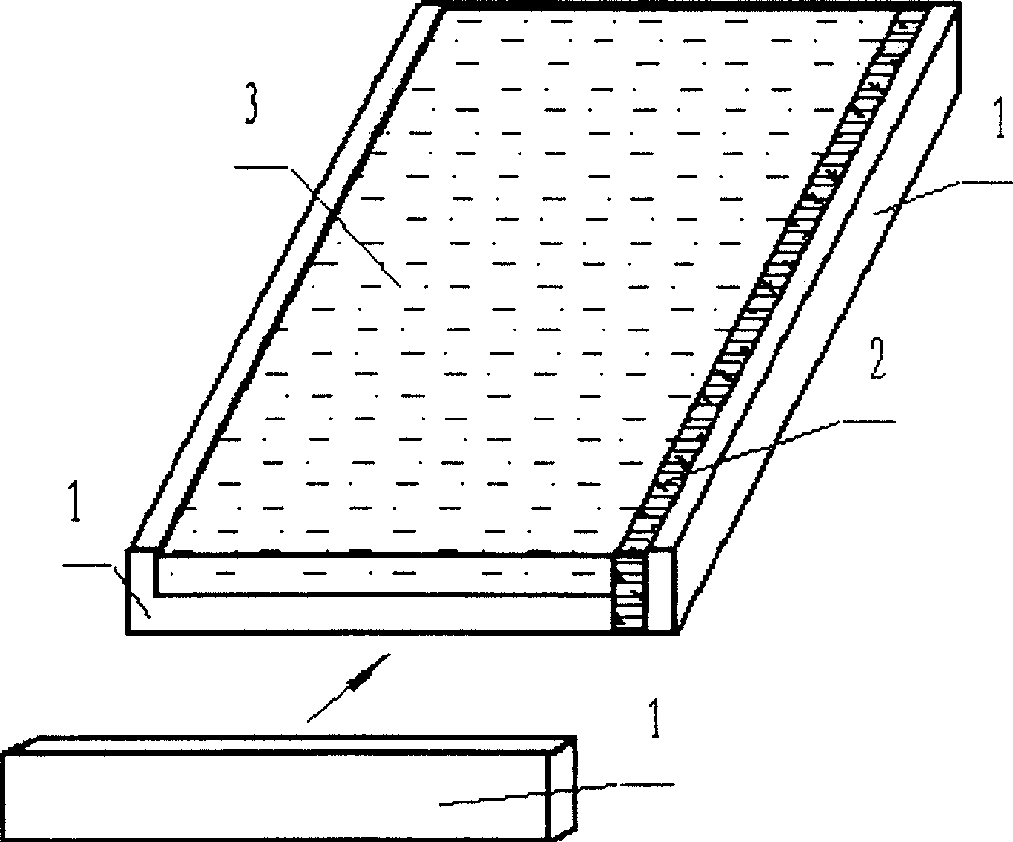

Cast-in-place concrete fire-proof thermal insulation compound external formwork and use method thereof

InactiveCN109707058AImprove insulation performanceImprove performanceHeat proofingWater-setting substance layered productCompound aThermal insulation

The invention relates to a cast-in-place concrete fire-proof thermal insulation compound external formwork and a use method thereof. A formwork body is provided with an internal protection layer, an internal binding layer, a compound thermal insulation layer, an external binding layer and an external protection layer from inward to outward in sequence; a trapezoid groove which is connected with aconcrete structure in a matched mode is formed in the inner side wall of the internal protection layer, and a coarse surface which is connected with the internal binding layer in a matched mode is arranged on the outer side wall of the internal protection layer; and the compound thermal insulation layer is formed by compounding a high wearing-resisting thermal insulation material and a high fire-proof thermal insulation material in an embedding and sleeving mode, the compound thermal insulation layer is arranged between the internal protection layer and the external protection layer, and coarse surfaces are arranged on the inner side wall and the outer side wall of the external protection layer. A phenomenon of crack and breakage of the peripheries of anchor holes is avoided, the thermal insulation layer has the properties of high strength, high fire resistance and high thermal insulation, the comprehensive performance is higher, the thermal insulation layer has the properties of fireproof and thermal insulation, the thermal insulation layer is not subjected to elastic deformation under the action of lateral pressure of concrete, high flatness of the fire-proof thermal insulationcompound external formwork after construction is ensured, and the binding intensity is high.

Owner:TIANJIN BEILE BUILDING MATERIAL

Reproducible surface high-intensity fire-proof plate and manufacture method thereof

InactiveCN102218876AHigh strengthGood fire and moisture resistanceSynthetic resin layered productsLaminationSurface layerPlastic waste

The invention discloses a reproducible surface high-intensity fire-proof plate and a manufacture method thereof, mainly relating to a composite material and an environmentally-friendly material plate used for indoor and outdoor decoration and used for manufacturing certain furniture. The reproducible surface high-intensity fire-proof plate is composed of a fire-proof surface layer, a foam plastic layer and a fiber enhanced layer. The reproducible surface high-intensity fire-proof plate has the advantages that the plastic foam layer is thermoset foam plastic waste and an enhanced material is mainly natural fiber, and is a plated prepared by hot-pressing shaping. The plate prepared by using the manufacture method is fireproofing, waterproofing and moistureproofing, has the advantages of no formaldehyde, good stability and good secondary machining performance, can be used for indoor and outdoor decoration and can be used for manufacturing furniture.

Owner:TIANJIN UNIV

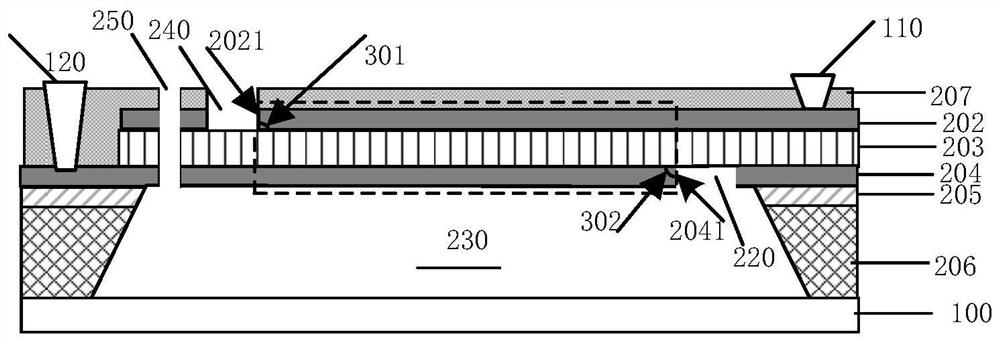

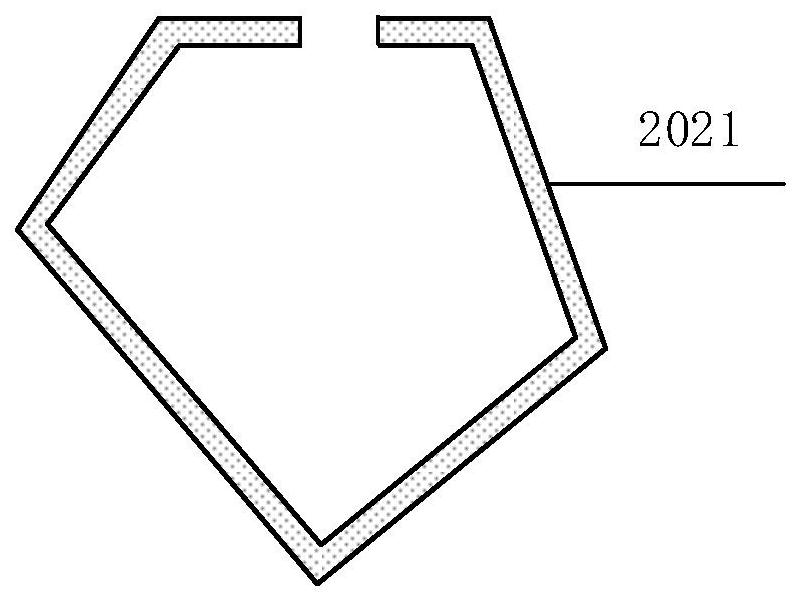

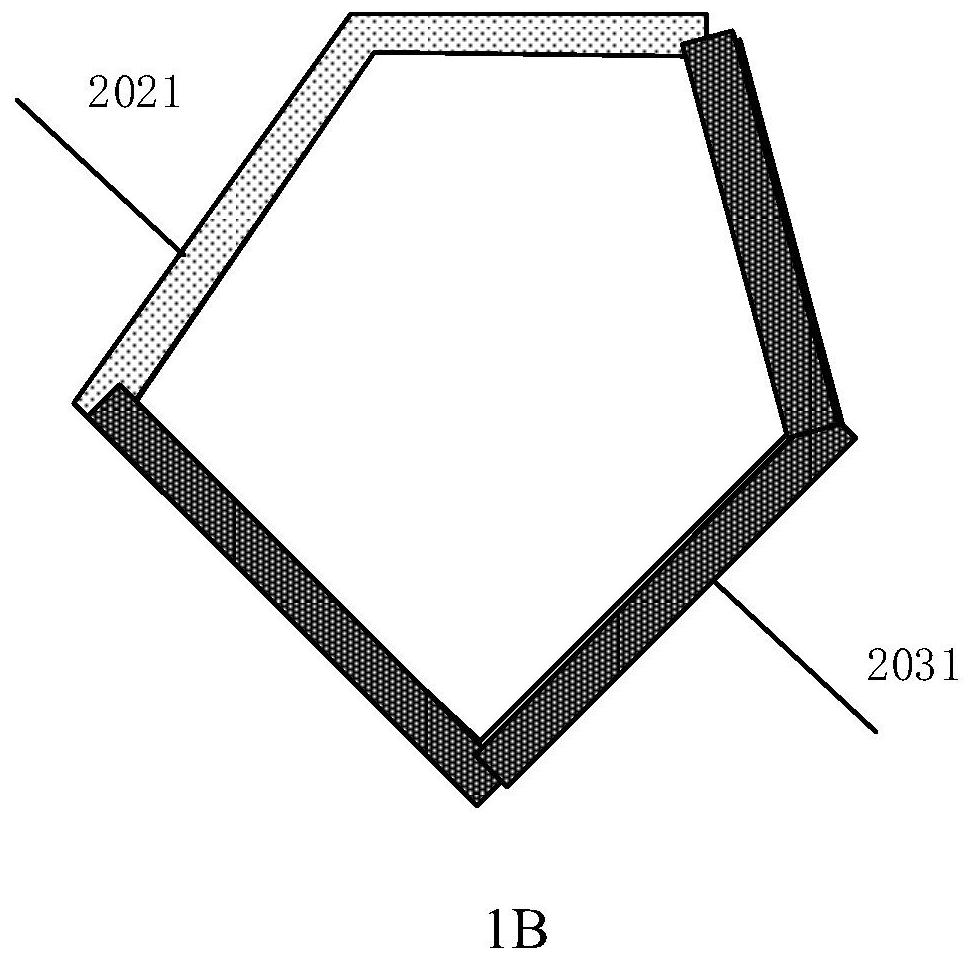

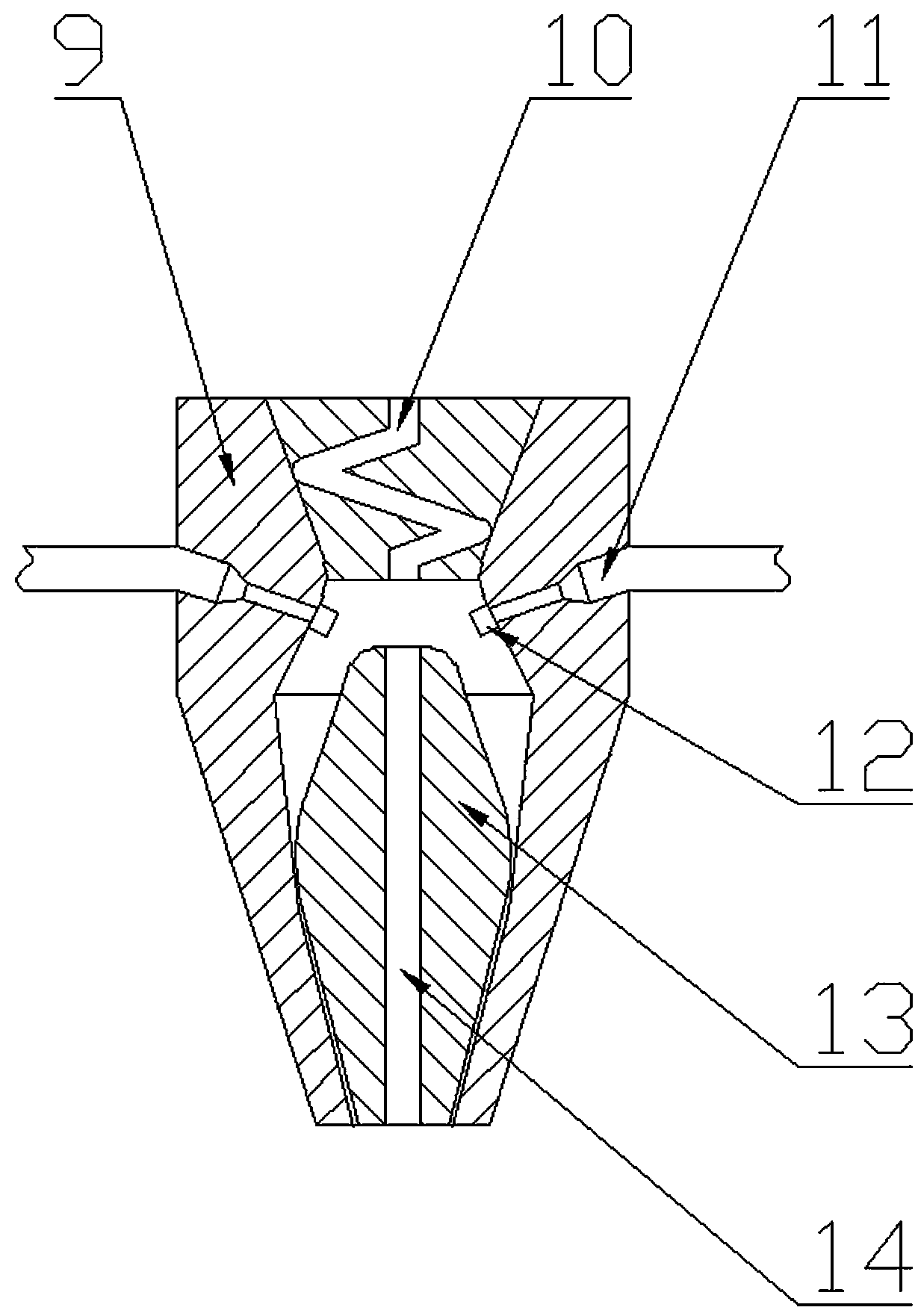

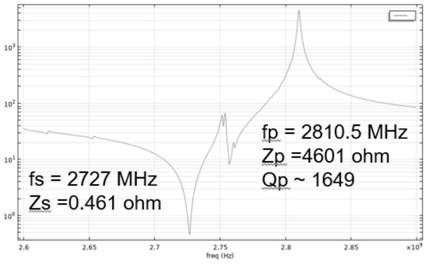

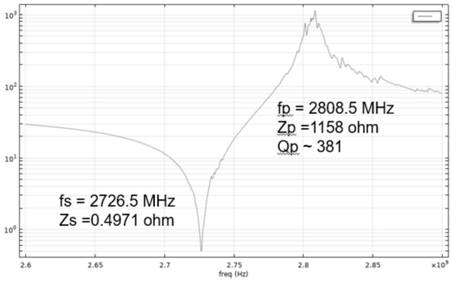

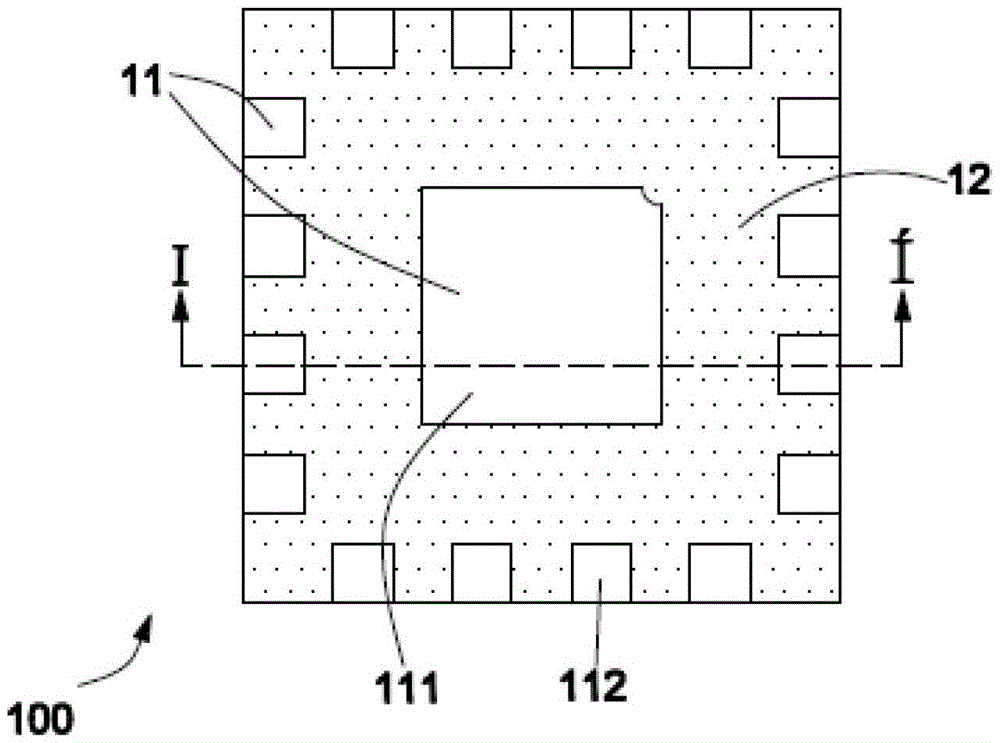

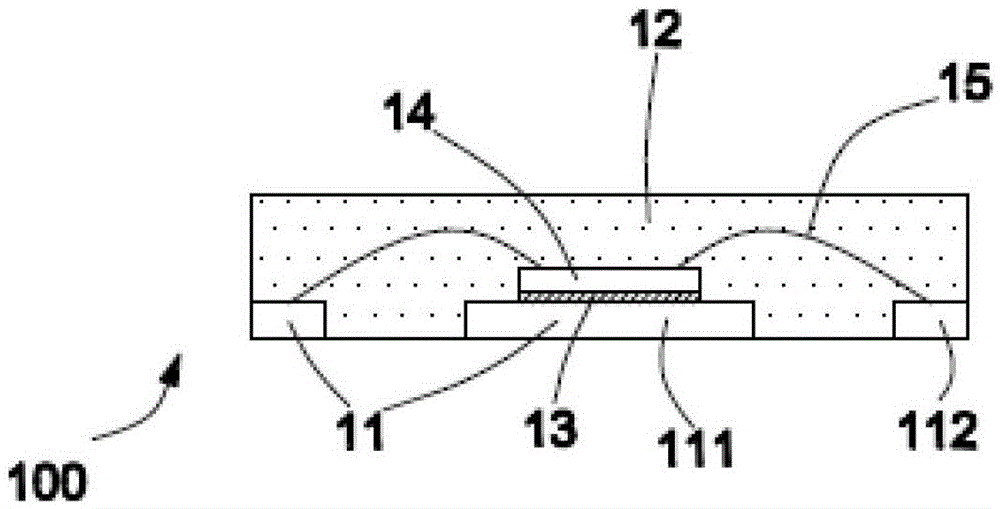

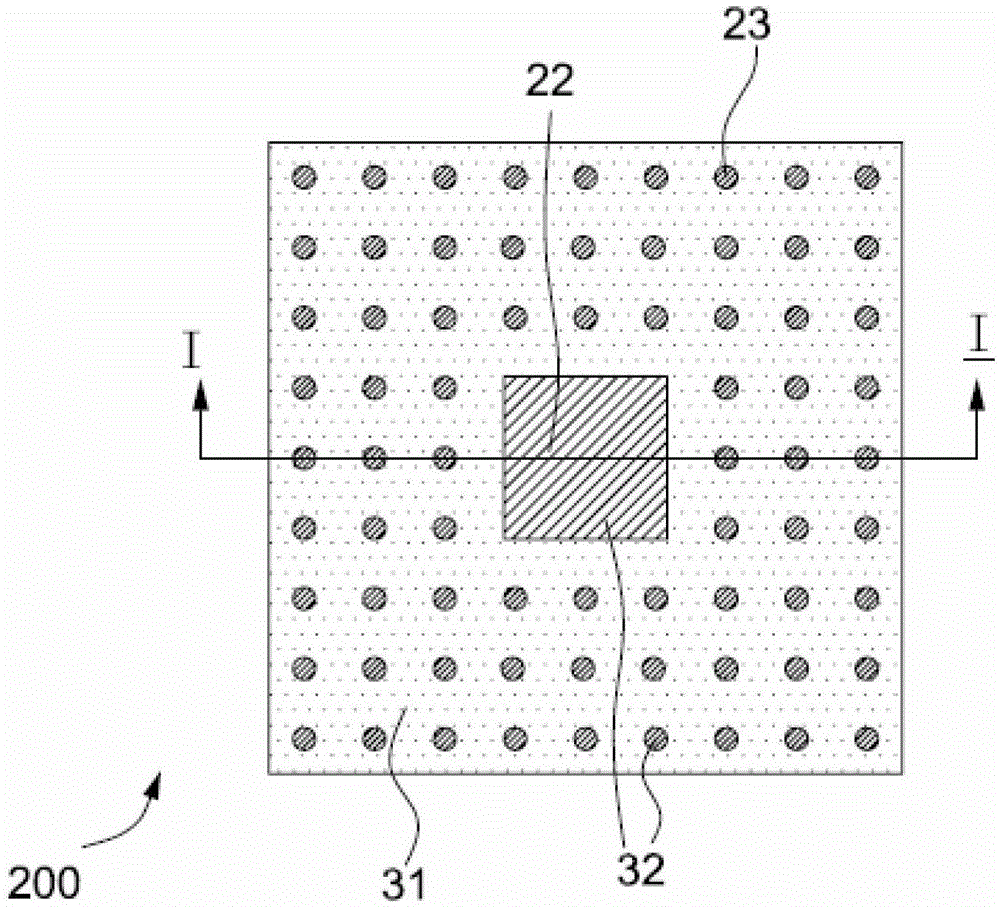

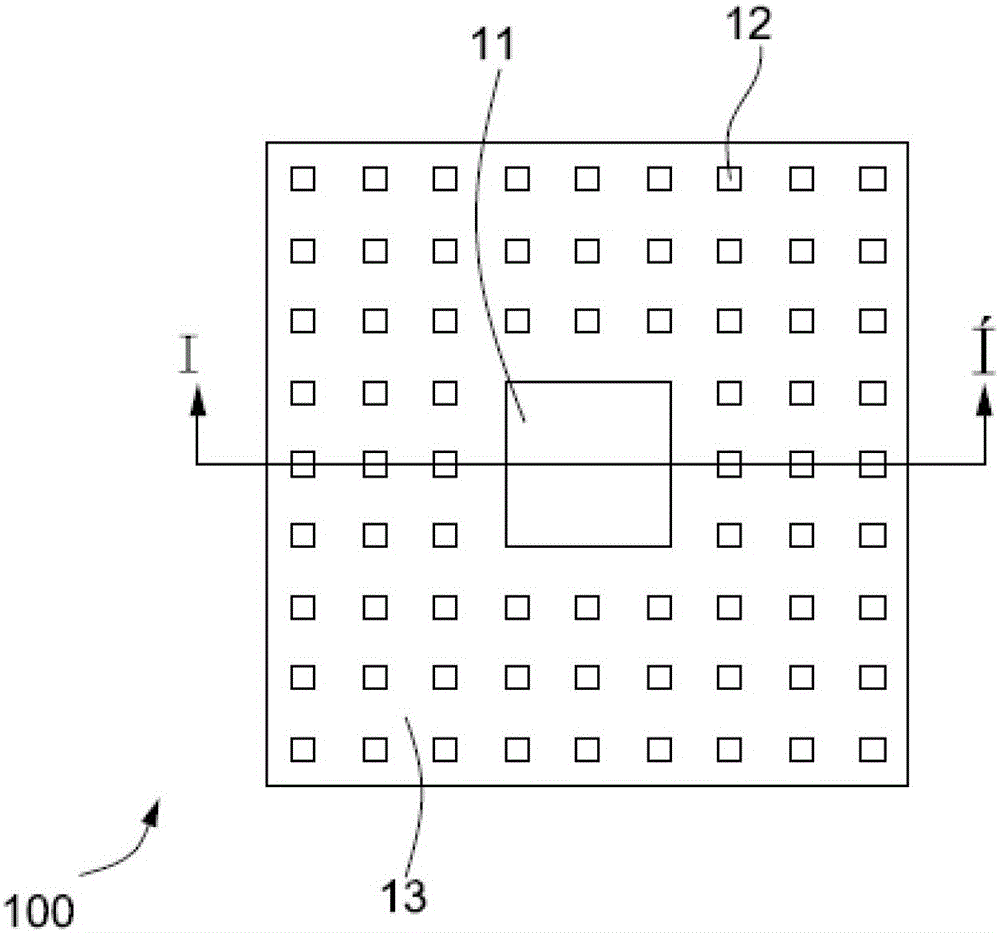

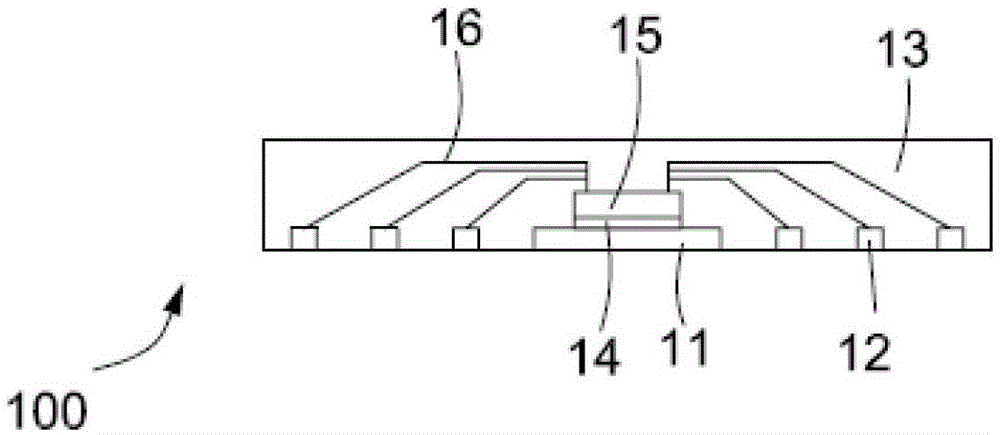

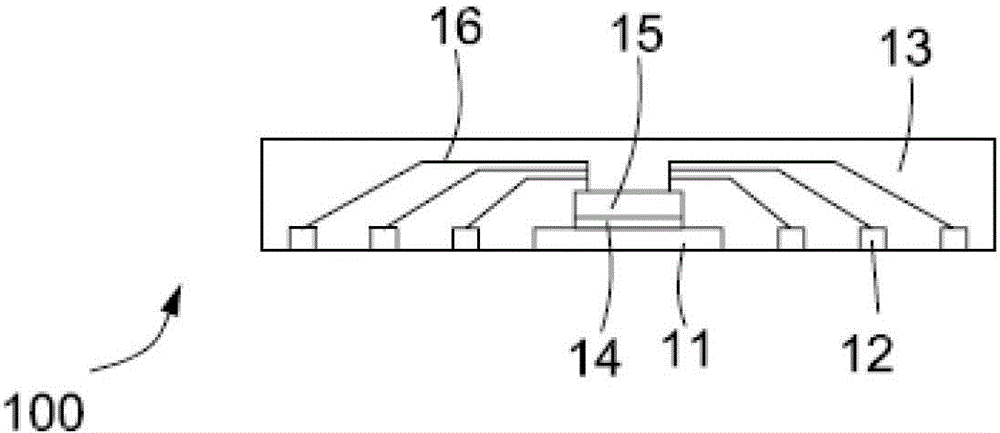

Film bulk acoustic resonator and manufacturing method thereof

The invention discloses a film bulk acoustic wave resonator and a manufacturing method thereof. The film bulk acoustic wave resonator comprises a first substrate; a supporting layer bonded on the first substrate, wherein a first cavity penetrating through the supporting layer is formed in the supporting layer; and a piezoelectric laminated structure covering the first cavity, wherein the piezoelectric laminated structure comprises a first electrode, a piezoelectric layer and a second electrode which are sequentially laminated from top to bottom, and the first electrode, the piezoelectric layerand the second electrode are overlapped in the direction perpendicular to the piezoelectric layer in an effective resonance area; the first electrode comprises a first side face and / or the second electrode comprises a second side face, at least part of the boundary of the effective resonance area comprises the first side face and / or the second side face, and the included angle between the first side face and / or the second side face and the surface of the piezoelectric layer is 85-95 degrees. According to the invention, the crystal orientation of the piezoelectric layer can be improved, the transverse wave loss of the resonator is reduced, and the quality factor of the film bulk acoustic resonator is improved.

Owner:NINGBO SEMICON INT CORP

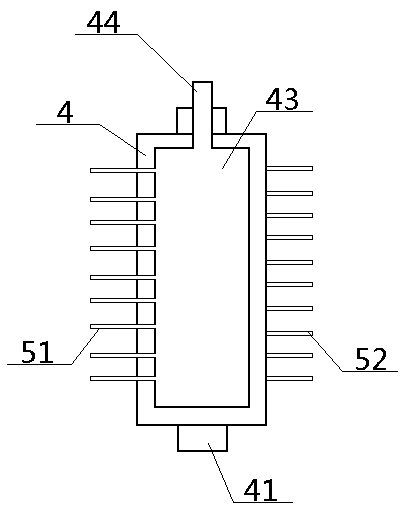

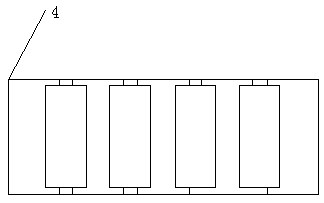

Honeycomb porous structure cotton preparation system

ActiveCN110126432AInterleaved implementationAchieve staggered arrangementLamination ancillary operationsControlling laminationFiberHoneycomb

The invention relates to a honeycomb porous structure cotton preparation system, which comprises a laying-stacking part, a combing part and a laying net part, wherein the material outlet of the laying-stacking part is communicated to the material inlet of the laying net part through the combing part, the laying-stacking part is a staggered laying-stacking system, and comprises a laying-stacking unit and a transfer unit, the combing part is a compacting puncture weaving system, and comprises a main conveying device and a finishing device, and the laying net part is a vertical laying net system,and comprises a reciprocating type cotton feeding device, a vertical cotton discharge device and a horizontal conveying belt. According to the present invention, the preparation system can simultaneously achieve the staggered arrangement between nets, between net fibers and between fibers, can achieve rich laying-stacking directions, and can form staggered multi-layer textile bodies with rich internal structures.

Owner:珠海信业包装制品有限公司

Glass film and preparation method thereof

InactiveCN110776834AImprove thermal stabilityImprove bonding fastnessFilm/foil adhesivesBulk chemical productionBenzimidazoleOxidation resistant

The invention discloses a glass film, which comprises the following raw materials by weight: 100 parts of a modified PET resin, 1-15 parts of modified master batch, 0.2-1.2 parts of a coupling agent and 1.5-3.5 parts of an additive, wherein the modified master batch is benzimidazoledione compound and modified PET resin coated inorganic oxide solid particles. According to the invention, the glass film has good comprehensive properties of heat insulation, ultraviolet resistance, interference resistance, oxidation resistance, easy maintenance and the like. The invention further discloses a preparation method of the glass film, wherein the comprehensive performance of the glass film is improved, the overall performance of the glass film is uniform, the service life of the glass film is prolonged, and the large-scale application and popularization is well facilitated.

Owner:宁波泰意德过滤技术有限公司

Glass ceramic table-board and its preparation method and application

InactiveCN1721350AGrain bonding denseEnvironmental protection is goodGlass furnace apparatusWork in processHigh wear resistance

The present invention relates to microcrystal glass top plate as one kind of building member and its production process and application. The production process includes the first sintering of the mixture of quartzite, limestone, etc. to form granular glass material; spreading the granular glass material inside one shaped frame and the second sintering to form the semi-finished microcrystal glass member; the third sintering of the cooled member inside one crystallizing furnace at 1110-1140 deg.c and temperature variation within 10 deg.c for 50-70 min; and polishing, grinding and shaping. The production process can form top plate with compact structure, no bubble, high wear resistance, easy trimming, good appearance and texture, and is easy to control.

Owner:许步晶

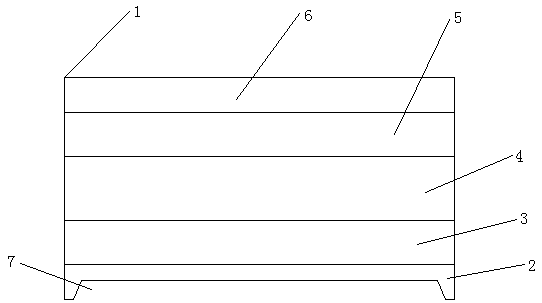

Manufacturing process of honeycomb porous structure cotton

ActiveCN110130000AInterleaved implementationRich stacking directionsNon-woven fabricsFiberStaging operation

A manufacturing process of honeycomb porous structure cotton comprises a laying stage operation process, a carding stage operation process and a lapping stage operation process which are performed sequentially, in the laying stage operation process, a laying part lays fiber webs, in the carding stage operation process, a carding part cards a product in the laying stage operation process, in the lapping stage operation process, a lapping part performs return type lapping on a product in the carding stage operation process, wherein the laying part is a staggered laying system, the carding part is a compaction weaving system, and the lapping part is a vertical lapping system. By the aid of the design, staggered arrangement between webs, webs and filaments and filaments can be realized simultaneously, the laying directions are rich, a staggered multilayer textile body can be formed, and the inner structures are rich.

Owner:平邑现代中药产业园有限公司

Planting method for Hawaii lawn

The invention discloses a planting method for a Hawaii lawn. The planting method comprises the following steps of 1, debris removal, wherein all debris and all weeds on the ground of planting land arecleaned up; 2, rotary tillage and flatting, wherein the planting land is subjected to deep rotary tillage and soil turning by using a rotary cultivator, and then the planting land is flatted; 3, pesticide spraying, wherein a weed killer is uniformly sprayed to the surface of the soil layer, which is subjected to rotary tillage and flatting, of the planting land; 4, ditching, wherein the plantingland is ditched; 5, seeding, wherein grass seeds are placed in ditches and then totally covered with soil; 6, fertilization, wherein after the lawn grows 1.5-2.5 centimeters, fertilization and thinning are conducted; 7, soft compression, wherein soft compression is conducted by using a roller press, and the lawn is compressed flat; 8, pruning, wherein pruning is conducted by using a trimmer, and after being pruned to a proper length, the lawn is made to grow transversely. The planting method for the Hawaii lawn is simple in process, short in planting cycle and small in fertilizing amount. Thelawn planted by using the planting method is light green in color, high in coverage rate, high in flatness, resistant to tread and drought and high in survival rate.

Owner:永兴县亿鹏农业专业合作社

Production method of vortex spun yarns applied to men's clothing warp-weft different-colored fabric

InactiveCN109629066AReduce energy costsReduce manufacturing costSucessive textile treatmentsTwo or more solvent application treatmentTextile technologyYarn

The invention relates to a production method of vortex spun yarns applied to a men's clothing warp-weft different-colored fabric and belongs to the technical field of fabric spinning. The production method comprises the following steps: first, feeding a plurality of yarn card slivers of yarns into a drawing-leasing machine by silver guiding rollers and executing raw material card sliver combination, sliver drafting, air-jet vortex spinning and yarn forming; second, knitting the yarns into a fabric through a yarn knitting machine; third, printing, dyeing and coloring the fabric by adopting a fabric printing and dyeing machine; fourth, completing the process of water absorption and dewatering of the fabric through a water absorbing and dewatering machine; fifth, drying and smoothing the fabric. The fabric has the advantages of compact structure, complete functions, excellent smoothness, good flatness, strong pilling resistance and strong washability, and the problems of more hairiness and unevenness of the yarns are solved. Black spots are greatly decreased, the cost for fabric repairing is greatly reduced, and meanwhile the energy consumption and production cost of two-for-one twisting for forming plied yarns can be reduced.

Owner:HANGZHOU ZHENGDA TEXTILE

Production method of floor

ActiveCN101337366BStrong hardnessStrong scratch resistancePolishing machinesPretreated surfacesFloor slabWear resistant

The invention discloses a method for producing nanometer crystal sand surface floor slabs. The production method comprises the steps of slicing timber, selecting slabs and grooving according to conventional techniques, and further comprises the steps of conducting the polishing treatment for floor slab base materials, including seventeen-layer multiple permeation paint application technique, thatis, applying two layers of water environmental protection primer, three layers of wear-resistant primer, nine layers of elastic primer, and three layers scraping-resistant finishing coat. The production method adopts the seventeen-layer multiple mutual-type permeation technique, that is, three plus two plus nine plus three, and utilizes the interactive permeation technique of nano-titanium paint molecules, so as to enable paint molecule layers to permeate into wood molecules. Through a plurality of layers of wear-resistant primer and hardening primer, and through leveling and a plurality of curing and sanding layers, the floor slab has high performance of super strong hardness, wear resistance, scraping resistance, oxidation and yellowing resistance. The paint surface adhesive force, the flexibility, and the scraping resistance of the floor slab greatly exceed those of the ordinary technical floor slab.

Owner:浙江永吉木业有限公司

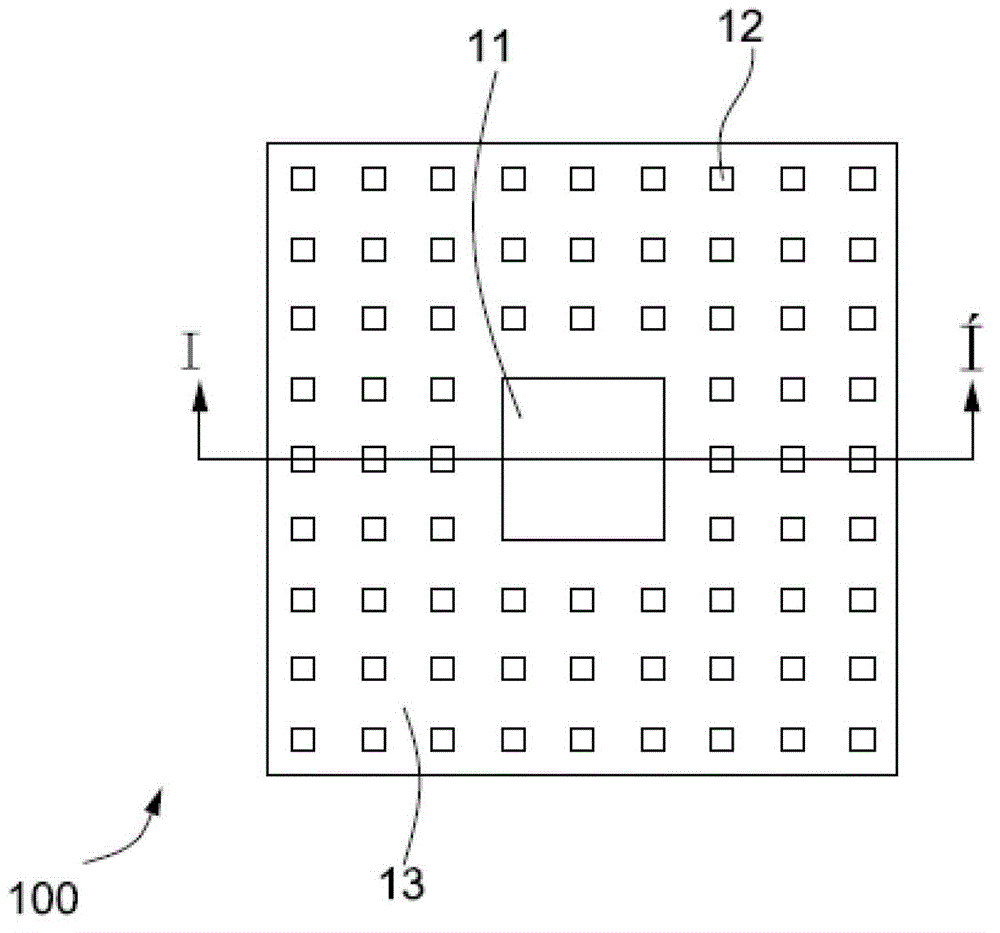

Film bulk acoustic resonator

The invention discloses a film bulk acoustic resonator, which comprises a first substrate; a supporting layer arranged on the first substrate, wherein a first cavity penetrating through the supportinglayer is formed in the supporting layer; and a piezoelectric laminated structure covering the first cavity, wherein the piezoelectric laminated structure comprises a first electrode, a piezoelectriclayer and a second electrode which are sequentially laminated from top to bottom, the first electrode, the piezoelectric layer and the second electrode are overlapped in the direction perpendicular tothe surface of the piezoelectric layer in an effective resonance area, and the effective resonance area is located above an area surrounded by the first cavity; a first groove penetrating through thepiezoelectric layer and the second electrode is formed in the piezoelectric laminated structure, the side wall, close to the effective resonance area, of the first groove is a first side face, the included angle between the first side face and the surface of the first electrode is 85-95 degrees, and part of the boundary of the effective resonance area is composed of the first side face.

Owner:NINGBO SEMICON INT CORP

Producing method of rayon acrylic fiber yarn-dyed and blended fabric

InactiveCN109722762ASmall scale productionSuitable for large-scale productionLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsWinding machineTextile technology

The invention relates to a producing method of a rayon acrylic fiber yarn-dyed and blended fabric, and belongs to the technical field of spinning. The method includes the steps of yarn loosening, preprocessing, blending and dyeing, post-processing and finished product forming. Blended fiber yarns are sent into a loose type winding machine through a roller yarn guide frame to be processed into a loose yarn bobbin, and preprocessing and blending and dyeing are completed in a bobbin dyeing device through a dye liquor adding device and an injection water warming device. The dyed yarn bobbin is loaded on a yarn weaving machine to be woven. The woven cotton acrylic fiber fabric is post-processed through a fabric leveling and unhairing machine and a fabric washing machine. The drying technological process of the cotton acrylic fiber fabric is completed through a roller rolling type fabric dewatering machine and a fabric drying machine. Finally, the winding and packaging process is completed through a fabric winding machine. The method has the advantages of being compact in structure, complete in function, high in efficiency, stable and precise in operating, simple in operation and stablein performance. The dryness degree of the fabric is improved, and the coloring quality and finish degree of the fabric are improved.

Owner:ZHEJIANG SAINTYEAR TEXTILE

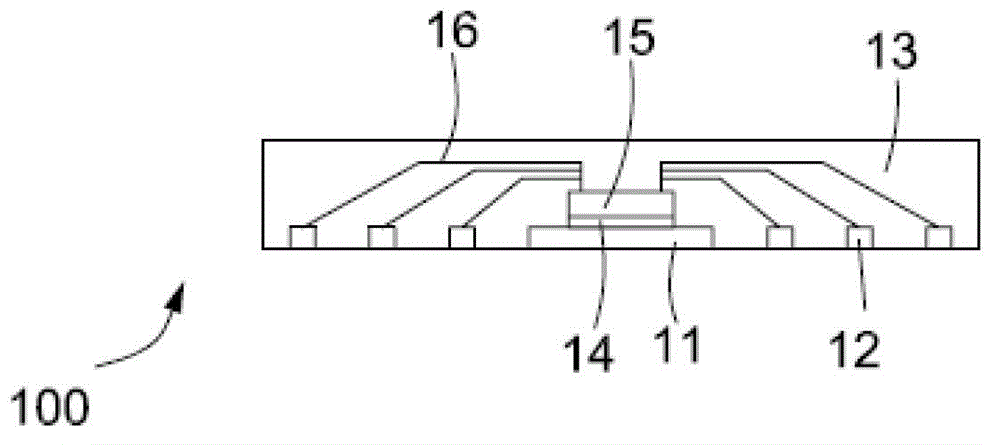

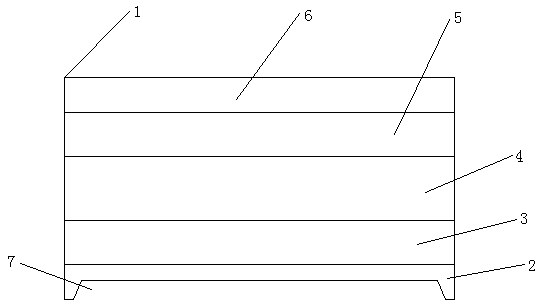

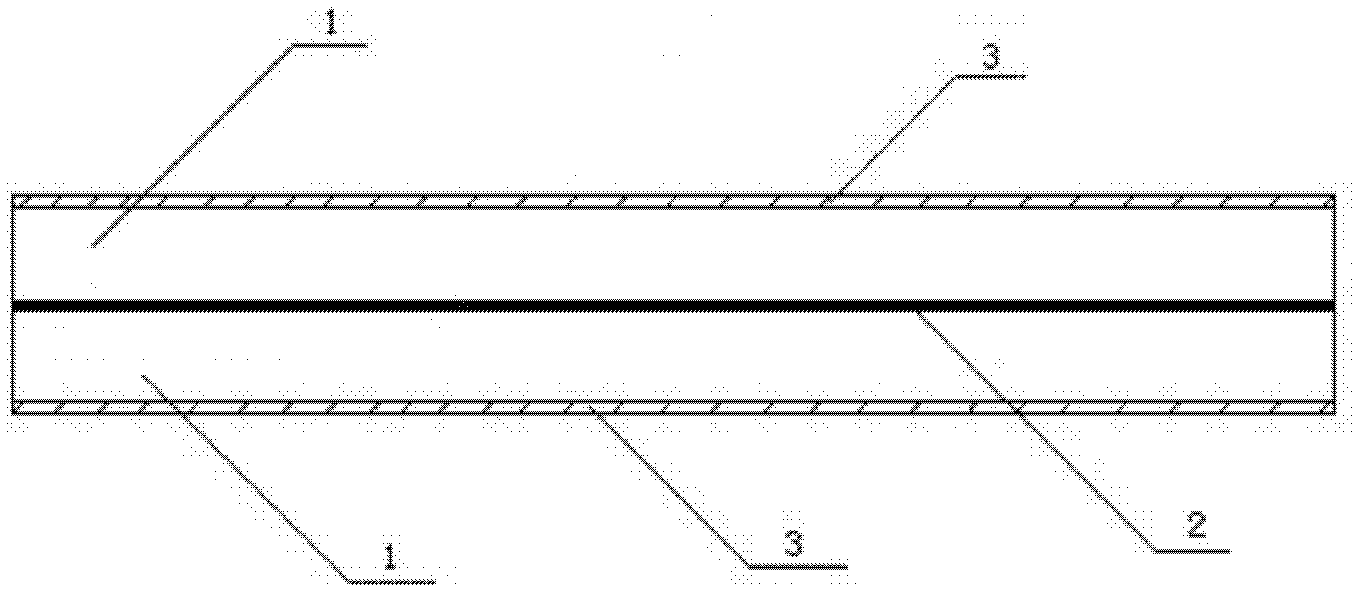

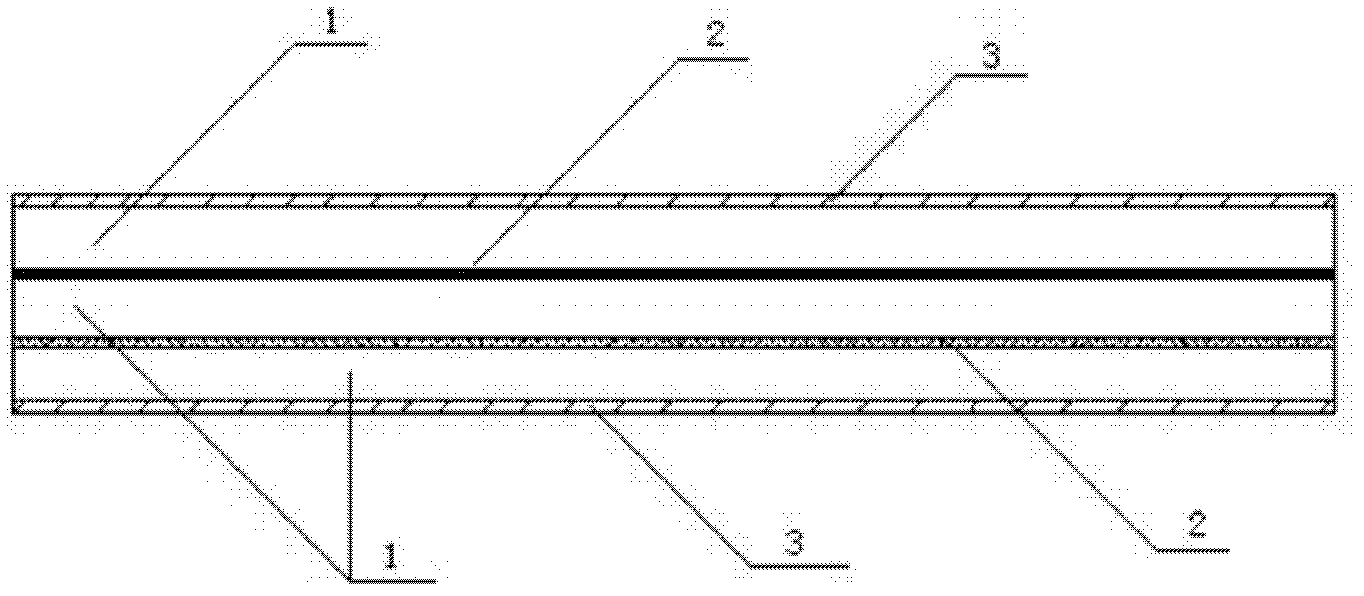

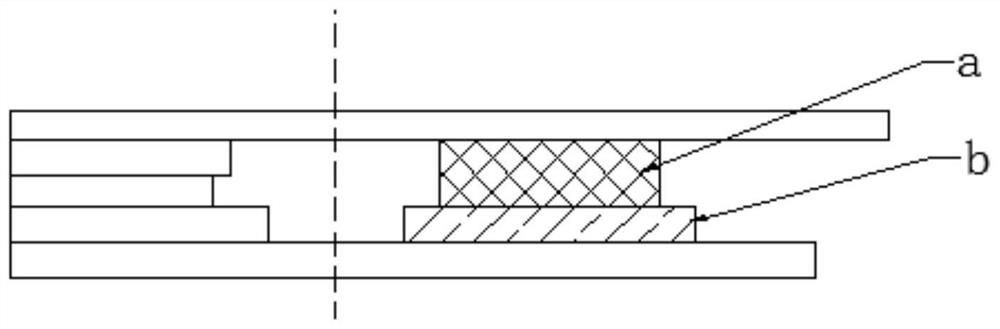

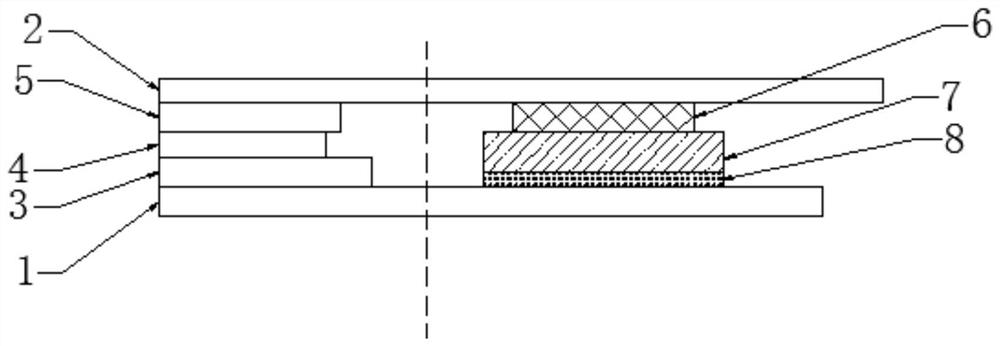

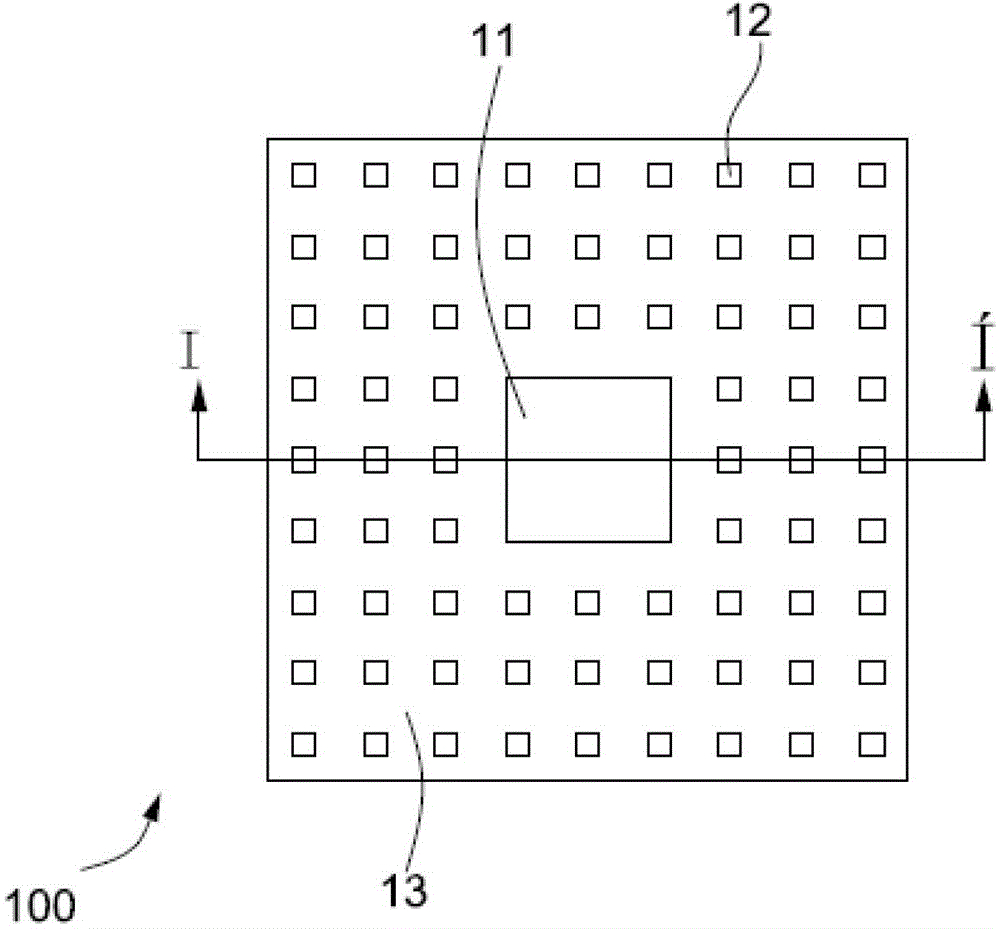

A touch display device

ActiveCN107422898BImprove flatnessStrong flatnessInput/output processes for data processingColor filmDisplay device

The invention discloses a touch display device. The touch display device comprises a first substrate and a second substrate opposite to the first substrate; a color film substrate is arranged at a part of the area, toward one side of the second substrate, of the first substrate; a polaroid is arranged on the color film substrate; a cementing layer is arranged on the polaroid; the areas of the first substrate and the second substrate are greater than the area of the color film substrate, the area of the polaroid and the area of the cementing layer; a gap is formed between the first substrate and the second substrate; and a rigid material layer is arranged in the gap, so that the strength of a single-layer area of the first substrate can be effectively increased and the local deformation resisting ability is improved.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

A method of manufacturing a semiconductor packaging device

ActiveCN103165475BHigh I/O densityImprove bonding qualitySolid-state devicesSemiconductor/solid-state device manufacturingChemical platingSemiconductor package

The invention discloses a manufacture method of a semiconductor package component. A chip load and a pin of a quad flat non-leaded package (QFN) semiconductor package component are not manufactured based on a lead frame structure which is manufactured in advance, while the chip load and the pin which are provided with a step structure are formed by the organic integration of etching, electroplating and chemical plating methods in the process of packaging technology. Seal package is carried out by adopting of plastic package materials, and after the plastic package is finished, the independent chip load and the pin are formed by adopting an etching method or a mechanical grinding method.

Owner:南通腾龙通信科技有限公司

A rewiring high-density AAQFN packaging device and its manufacturing method

ActiveCN103050452BHigh densitySmall sizeSemiconductor/solid-state device detailsSolid-state devicesScreen printingPlastic packaging

Owner:南通腾龙通信科技有限公司

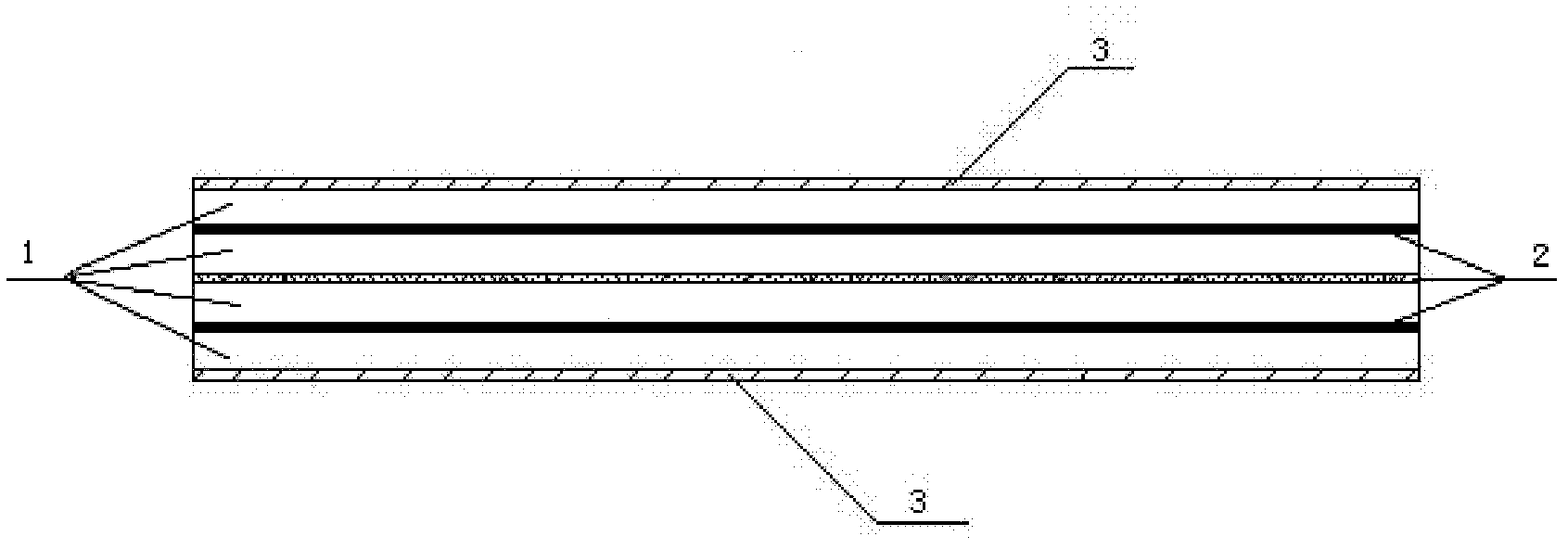

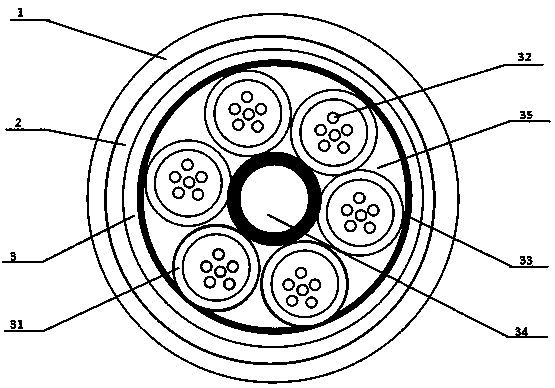

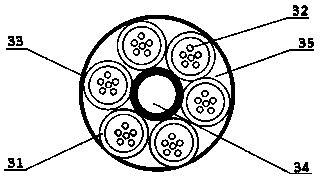

Tearing and biting resisting optical cable and preparation method thereof

ActiveCN107831570AImprove plasticizing effectImprove surface qualityFibre mechanical structuresFiberEngineering

The invention relates to a tearing and biting resisting optical cable and a preparation method thereof. The optical cable comprises a sheath 1. A sheath II is sleeved by the sheath I. A hollow structure is formed in the sheath II and at least one loose sleeve is arranged in the sheath II. At least 2n fibers are arranged in each loose sleeve, wherein n is a positive integer and 1<=n<=6. The preparation method comprises steps of S1, preprocessing of fiber cores; S2, forming of the sheaths; S3, cooling of cables; and S4, wire withdrawing of finished products. According to the invention, the optical cable is advantaged by big tensile modulus, high tearing resisting performance and tearing and biting resisting ability.

Owner:丰果(中国)有限公司

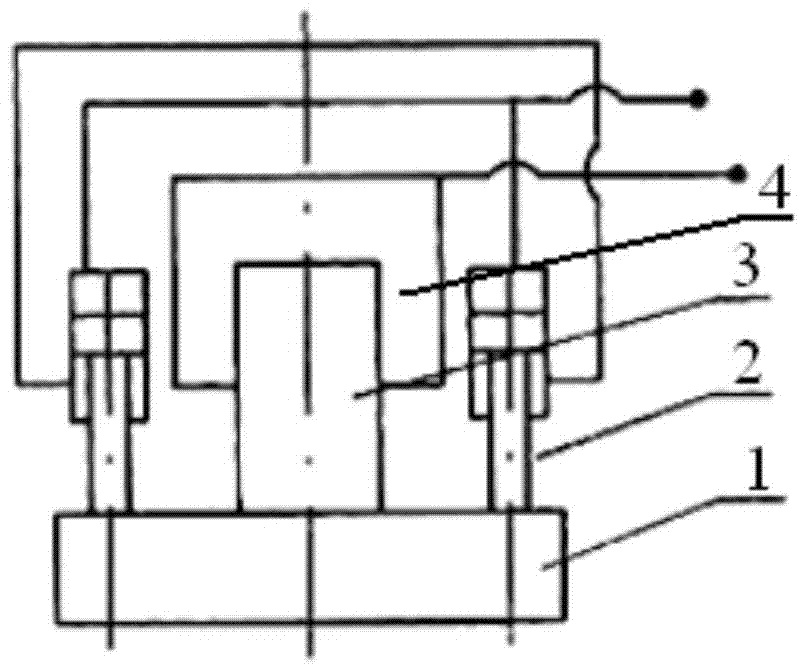

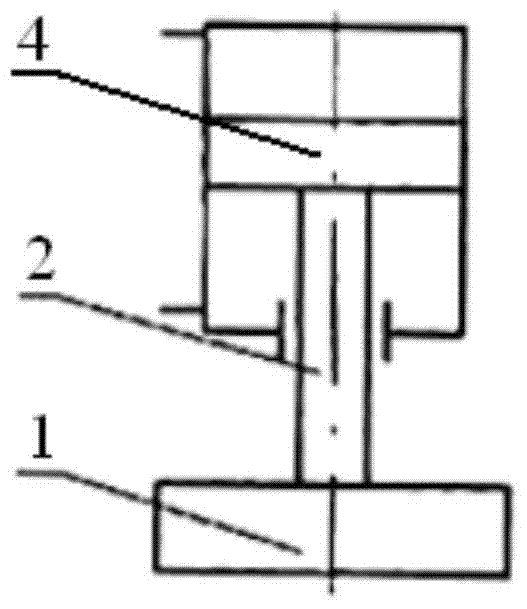

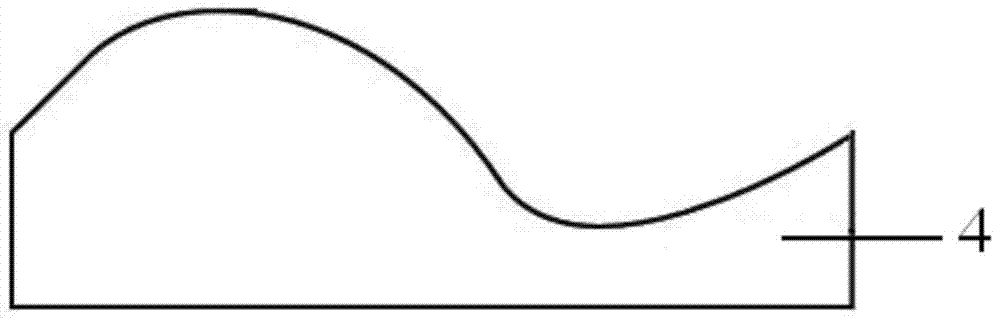

A three-dimensional undulating surface vitrified brick forming device

ActiveCN105082328BStrong acid resistanceStrong dirt resistanceCeramic shaping apparatusBrickEngineering

The invention relates to a vitrified brick molding device with a stereoscopic fluctuating face. The vitrified brick molding device comprises a movable beam, pistons, a plunger and a mold. The pistons and the plunger are connected to the movable beam and driven by the movable beam to move up and down. The mold is movably connected with the pistons and the plunger and driven by the pistons and the plunger to conduct mold press operation. The inner side face of the mold is a fluctuating concave-convex face. The fluctuating height of the concave-convex face is larger than 1 mm. Compared with the prior art, a vitrified brick manufactured through the molding device has better decoration and better comprehensive beneficial effects of durability, freezing resistance, dirt resistance, corrosion resistance, abrasion resistance and the like than similar products.

Owner:SHANGHAI YUEXIN HEALTH GRP CO LTD +1

Manufacturing method of pcb board surface protection

InactiveCN105530763BReduce misalignmentSimple processPhotodevelopable thick filmNon-metallic protective coating applicationCooking & bakingResist

The invention discloses a manufacturing method used for a PCB (printed circuit board) and capable of protecting the PCB surface. The manufacturing method comprises the following steps of pasting photo-sensitive resist on the surface of the PCB; manufacturing a negative film and drawing patterns on the negative film, wherein a light tight pattern is arranged in a position, corresponding to a position where a protection layer is not required to cover the PCB, of the negative film, and the rest positions of the negative film are light-transmitting; putting the PCB in an exposure machine, after enabling the negative film to be aligned with the PCB, placing the negative film on the PCB; starting the exposure machine, wherein UV light from the exposure machine irradiates the negative film, and the UV light transmits the light-transmitting part of the negative film to be irradiated on the PCB obtained in the first step; baking; developing; and baking. The manufacturing method is simple in manufacturing process and environment-friendly; the manufactured PCB is high in flatness; the adhesive force of the protection layer is enhanced; and an accurate windowing region is obtained.

Owner:江西芯创光电有限公司

Manufacturing method for rewiring quad flat no-lead (QFN) packaging component

InactiveCN103065975BSmall sizeImprove yieldSolid-state devicesSemiconductor/solid-state device manufacturingScreen printingChemical plating

Owner:BEIJING UNIV OF TECH

Heat-insulating ultraviolet-resistant glass sticker film and preparation method therefor

ActiveCN110746750AParticle size controllableUniform shape distributionBulk chemical productionSalicylic acid esterFluidized bed

The invention discloses a heat-insulating ultraviolet-resistant glass sticker film and a preparation method therefor. The preparation method comprises the steps: S1: dispersing a salicylate compound and PET resin into an aqueous solution of ethanol, so as to form a coating solution; S2: adding metal oxide solid particles into a fluidized-bed reactor, and introducing coating solution entrained supercritical carbon dioxide fluid to coat surfaces of the metal oxide solid particles with the salicylate compound and the PET resin, so as to obtain modified metal oxide solid particles; and S3: uniformly mixing the modified metal oxide solid particles, a couplant, additives and PET to form a casting solution, and pouring the casting solution into a mold, thereby obtaining the glass sticker film. According to the preparation method for the glass sticker film, disclosed by the invention, the heat-insulating and ultraviolet-resistant properties of the glass sticker film are improved, the global performance of the glass sticker film can be more uniform, the service life of the glass sticker film is prolonged, and thus, large-scale popularization and application are better facilitated.

Owner:湖南泉想湖智能科技有限公司

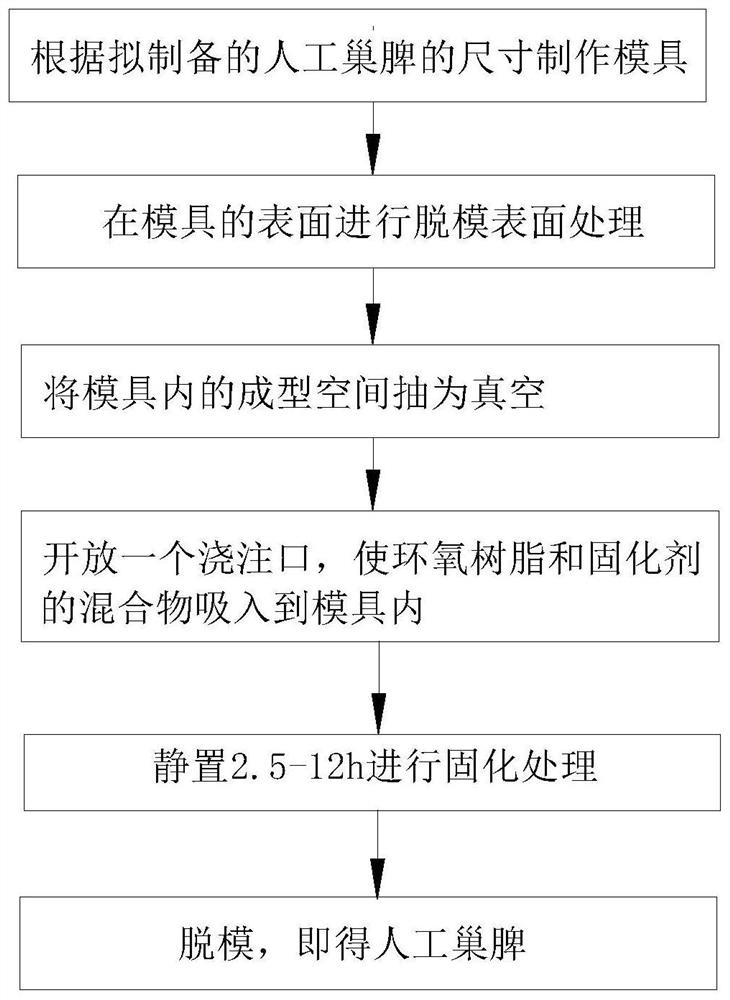

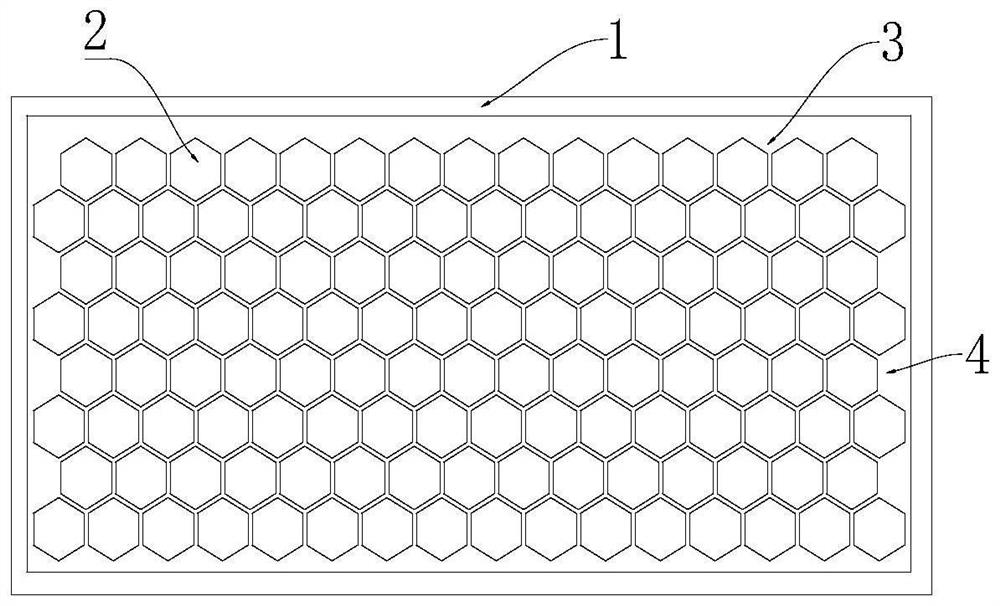

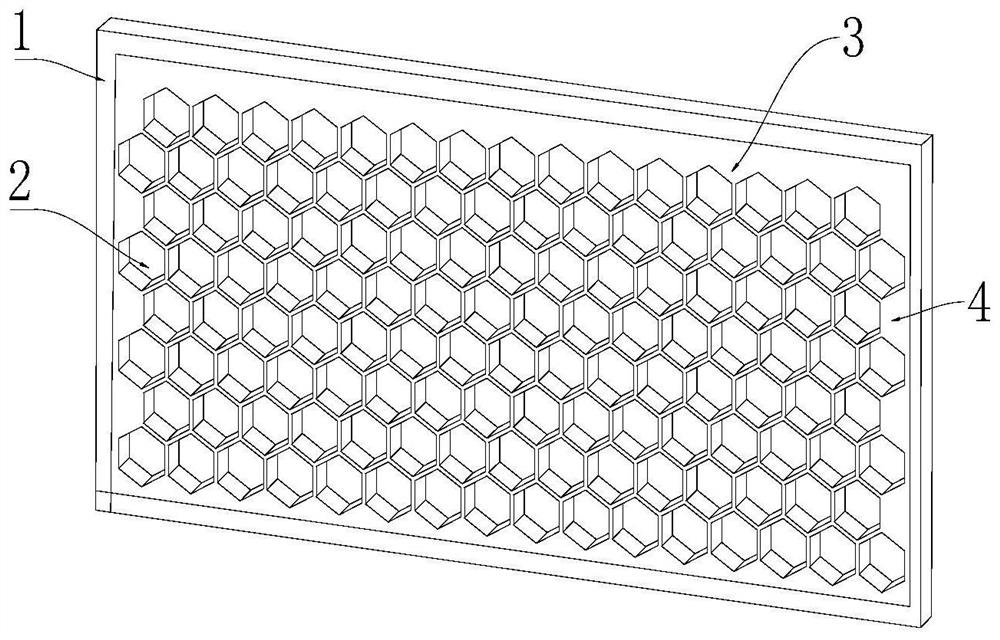

Artificial honeycomb and its preparation method

The invention relates to the technical field of agricultural product breeding devices, in particular to an artificial honeycomb and a preparation method thereof. The artificial honeycomb includes a frame, and a honeycomb cell composed of a plurality of regular hexagonal columnar honeycomb cells is arranged in the frame, and the honeycomb cell is integrally molded by epoxy resin. Through the above technical solution, the artificial honeycomb provided by the present disclosure can solve the problem of poor structural stability of the honeycomb in the prior art.

Owner:叶祎

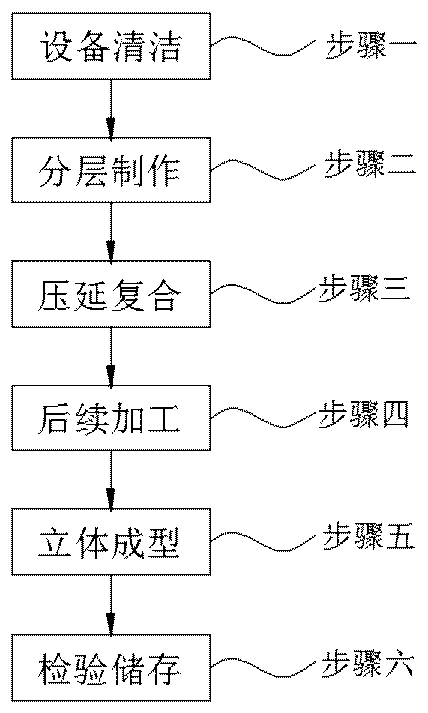

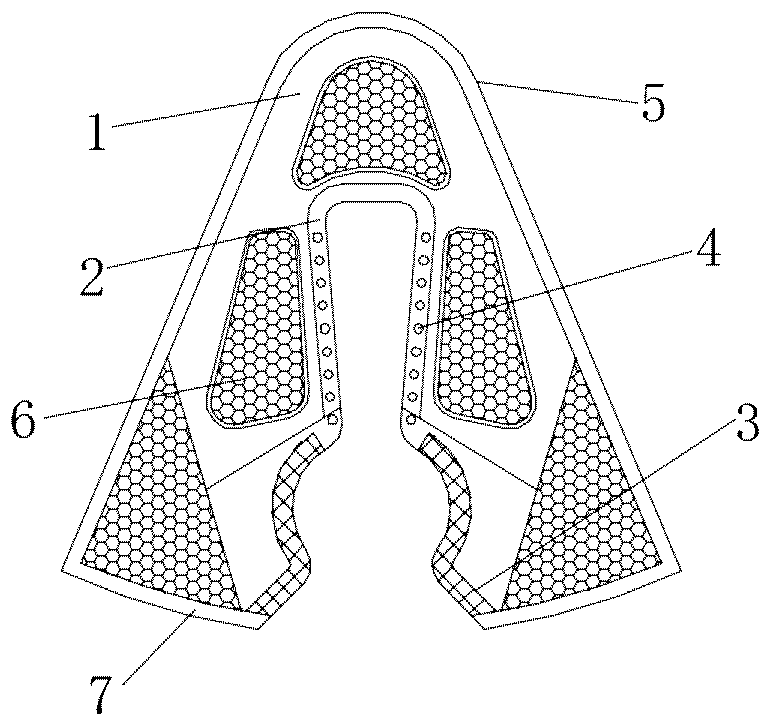

Stereoscopically formed vamp and processing technology

PendingCN112641169AEliminate the feeling of hard and heavyAdjustable thicknessDomestic footwearUpperPolymer sciencePolyurethane adhesive

The invention discloses a stereoscopically formed vamp and a processing technology, the stereoscopically formed vamp comprises a vamp main body, a front lining, a rear piece, eyelets, a sole edge, a decorative piece and a rear patch, the vamp main body comprises a TPU polyurethane adhesive film, a TPU closed-cell polyurethane foaming layer and a PU polyurethane layer; wherein the TPU polyurethane adhesive film, the TPU closed-cell type polyurethane foaming layer and the PU polyurethane layer are sequentially calendered and compounded from top to bottom; the processing technology comprises the following steps: 1, equipment cleaning; 2, layered manufacturing; 3, calendering and compounding; 4, subsequent processing; 5, three-dimensional forming; and 6, inspecting and storing; the vamp has the characteristics of light volume, mildew resistance, bacteria resistance, scratch resistance, tear resistance and the like; the flatness and the softness uniformity are improved by more than several times, and the vamp is super-strong, resistant to low temperature and resistant to stretching; the medium-high-low temperature seamless process is directly used for three-dimensional forming, a bottom sheet is not needed, and the tedious part of the traditional seamless process is omitted; and the vamp can also be applied to furniture, sofas and other products.

Owner:泉州凯美亚新材料科技有限公司

Production method of four-side elastic flame-retardant lining cloth

PendingCN112244397AImprove adhesionImprove flatnessSucessive textile treatmentsWeft knittingFlame resistanceYarn

The invention discloses a production method of four-side elastic flame-retardant lining cloth. The production method comprises the following steps: enabling POY to sequentially pass through a yarn cutter, a roller I, a hot box I, a cooling plate, a false twister, a roller II, a hot box II, an interlacer, a black roller, a roller III, an oil wheel and a winder; placing DTY on a creel, and then stably conveying silk to a yarn conveying device; feeding the lining cloth into a steam furnace for preshrinking; padding the lining cloth with flame-retardant liquid; and transferring the lining cloth byusing a carving roller, and uniformly transferring the hot melt adhesive powder on the surface of the fabric cloth in a dot shape. The flame-retardant lining cloth has the beneficial effect that theproduced lining cloth has good flame-retardant performance.

Owner:湖州紫琅衬布有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com