Production method of vortex spun yarns applied to men's clothing warp-weft different-colored fabric

A technology of vortex spinning and production method, applied in the field of fabric spinning, can solve the problems of high hairiness of spun yarn, poor product quality and high production cost, and achieve the effects of excellent finish, complete functions and good flatness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0035] Embodiment: As shown in the figure, a production method of vortex spinning yarn applied to fabrics of different colors in warp and weft for men's clothing comprises the following steps:

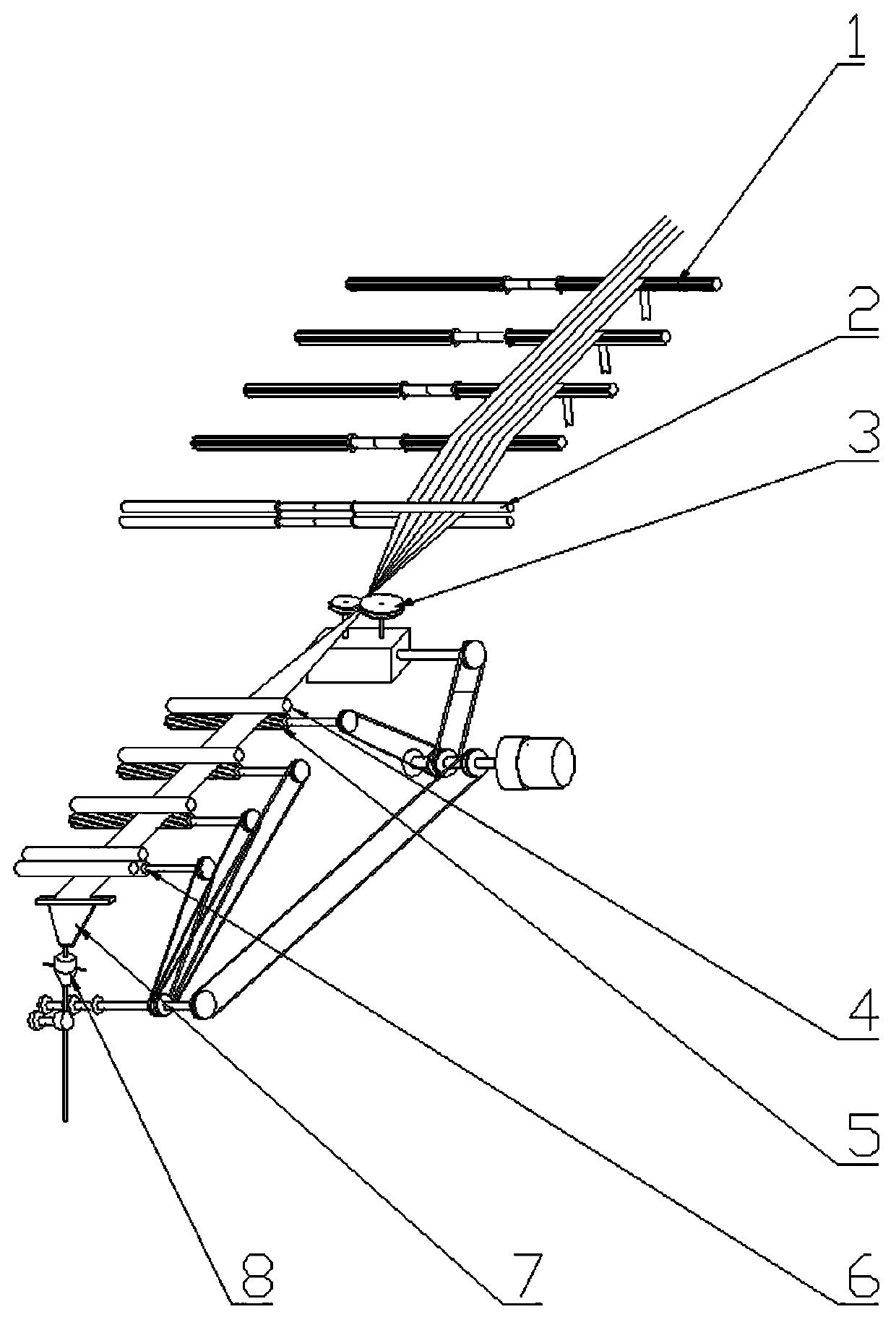

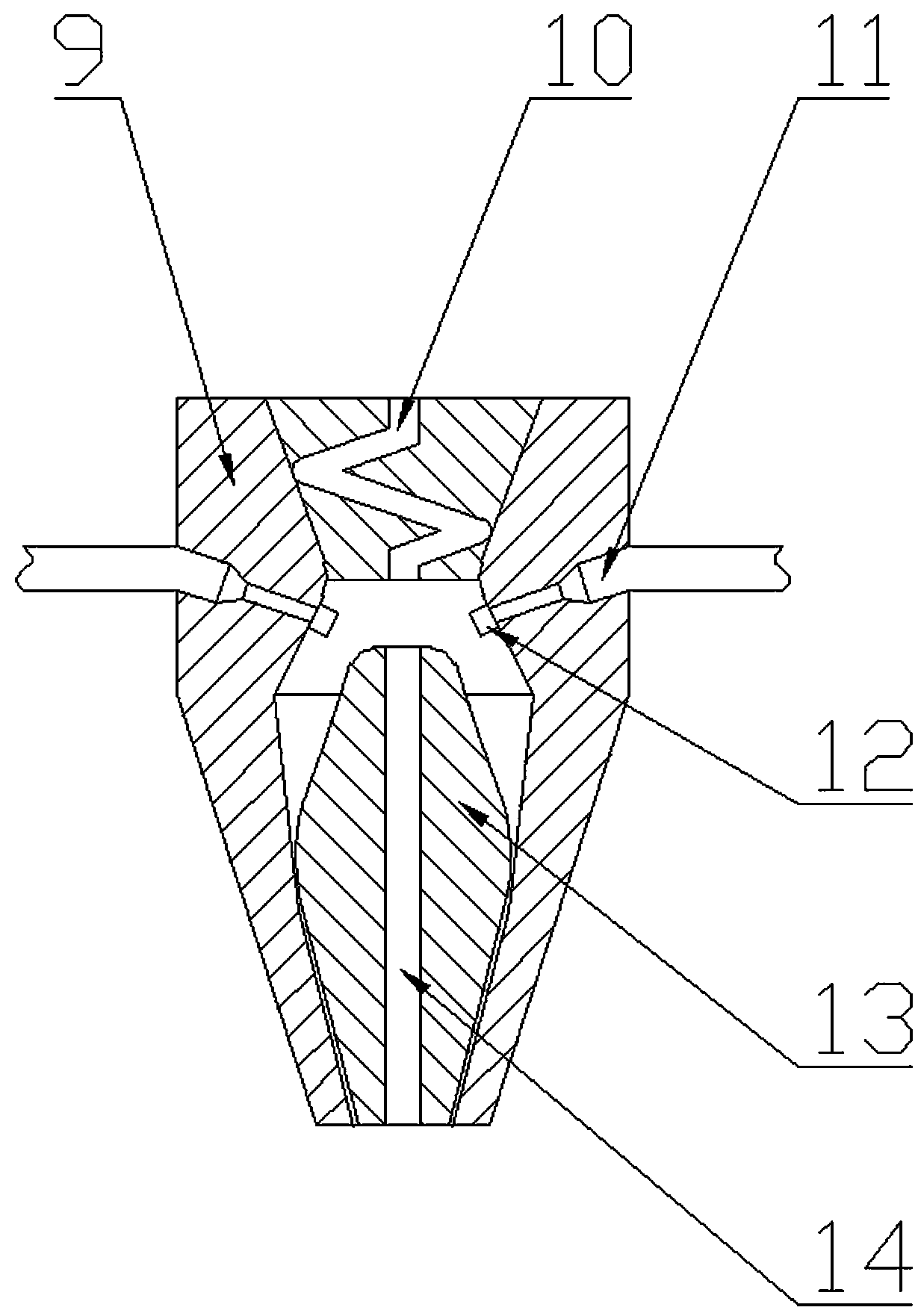

[0036] The first step: Yarn raw sliver drawing and vortex spinning process: 4 sets of yarn raw sliver are fed to the drawing and splitting machine by the guide roller 1, through raw sliver merging, sliver drafting, air-jet vortex spinning and The process by which yarn is slivered so that it is processed into yarn for weaving.

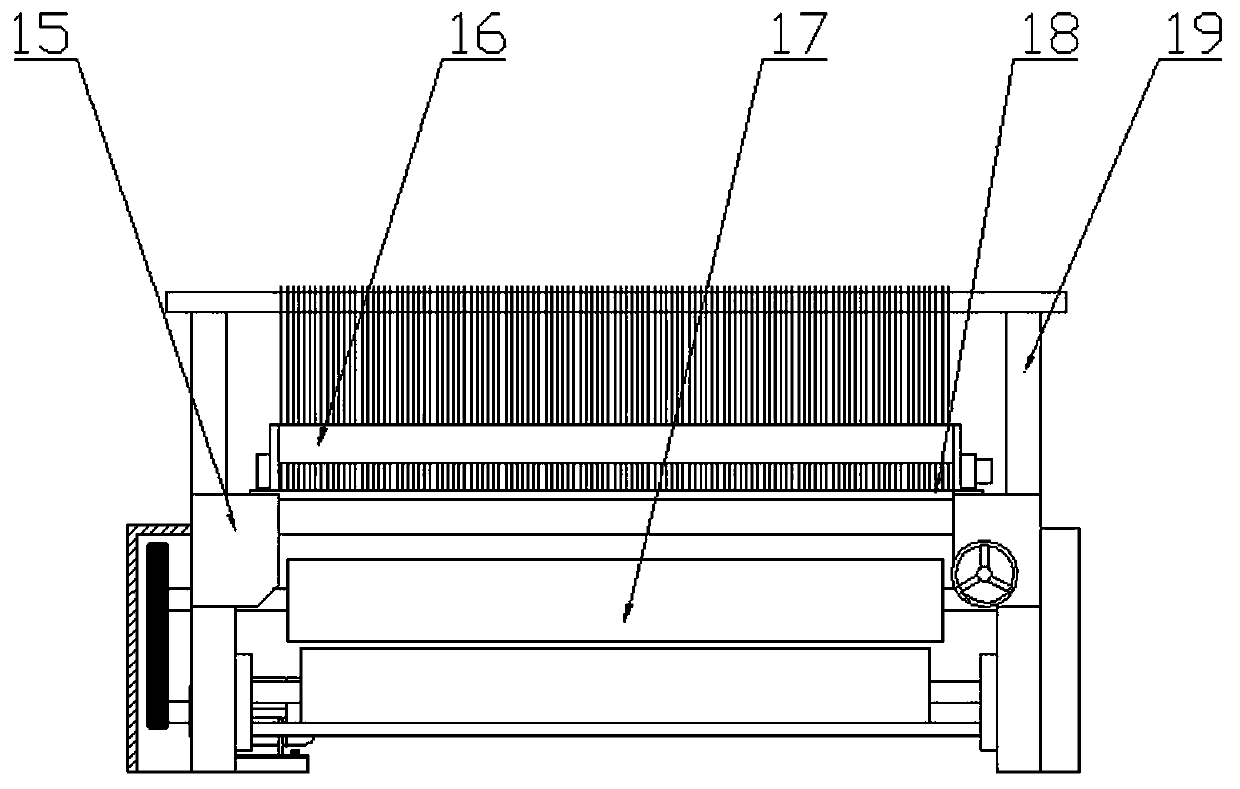

[0037] Second step: the yarn is woven into a fabric process: the yarn formed by the drawing and splitting machine is woven on the yarn weaving frame 15, first the yarn is shuttled to the weaving wire frame 19 to form a warp, and then the yarn is Line shuttles to form weft on warp and weft weaving shuttle frame 16, then under the stretching effect of drive roller 17, the latitude on weaving warp and weft weaving shuttle frame 16 and the warp on weaving wire frame 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com