Reproducible surface high-intensity fire-proof plate and manufacture method thereof

A manufacturing method and fireproof board technology, applied in the direction of chemical instruments and methods, synthetic resin layered products, lamination devices, etc., can solve the problems of low production cost, ecological environment damage, etc., achieve high flatness, simplify production process, Strong anti-deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Clean the styrene-acrylonitrile copolymer foam plastic waste, and then grind it into 20-100 mesh powder.

[0028] (2) Weigh 34.43 kg of the styrene-acrylonitrile copolymer foam plastic waste powder in (1) and preheat at 100° C. for 30 minutes.

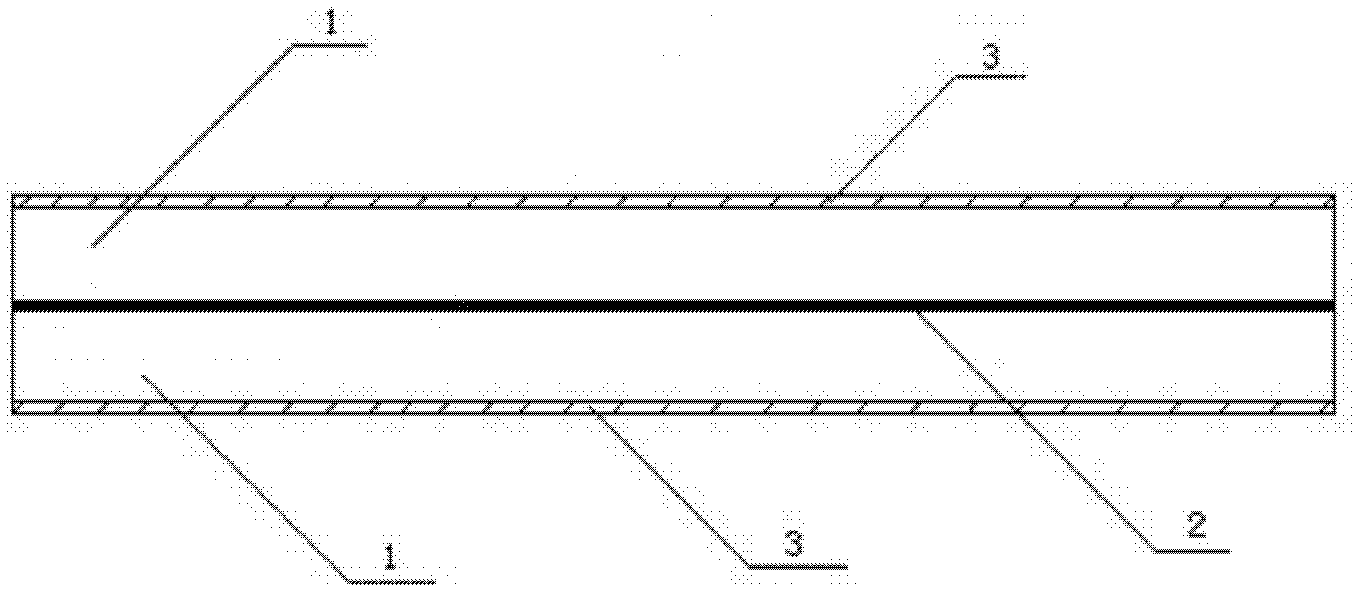

[0029] (3) Put the preheated raw material into the mold of the hot press machine, and lay 6.07kg of reinforcing fibers evenly in three layers in the raw material.

[0030] (4) Hot pressing, the pressure is 20MPa, the temperature is 200°C, and the time is 30min.

[0031] (5) Carry out edge sawing and sanding on the prepared board, and paste a layer of fireproof surface layer on the upper and lower surfaces respectively to make a finished board of standard size.

[0032] Wherein the styrene-acrylonitrile copolymer foamed plastic waste powder is 20-100 mesh powder, and the reinforcing fiber used is natural jute fiber, and jute hemp fiber is arranged along the long side in the model middle layer, and the fiber weight of every l...

Embodiment 2

[0034] (1) Clean the styrene-acrylonitrile copolymer foam plastic waste, and then cut it into 0.5-2cm 3 block, and grind the block into 20-100 mesh powder.

[0035] (2) Weigh 38.25kg of the styrene-acrylonitrile copolymer foam plastic waste powder in (1) and preheat at 100°C for 30min.

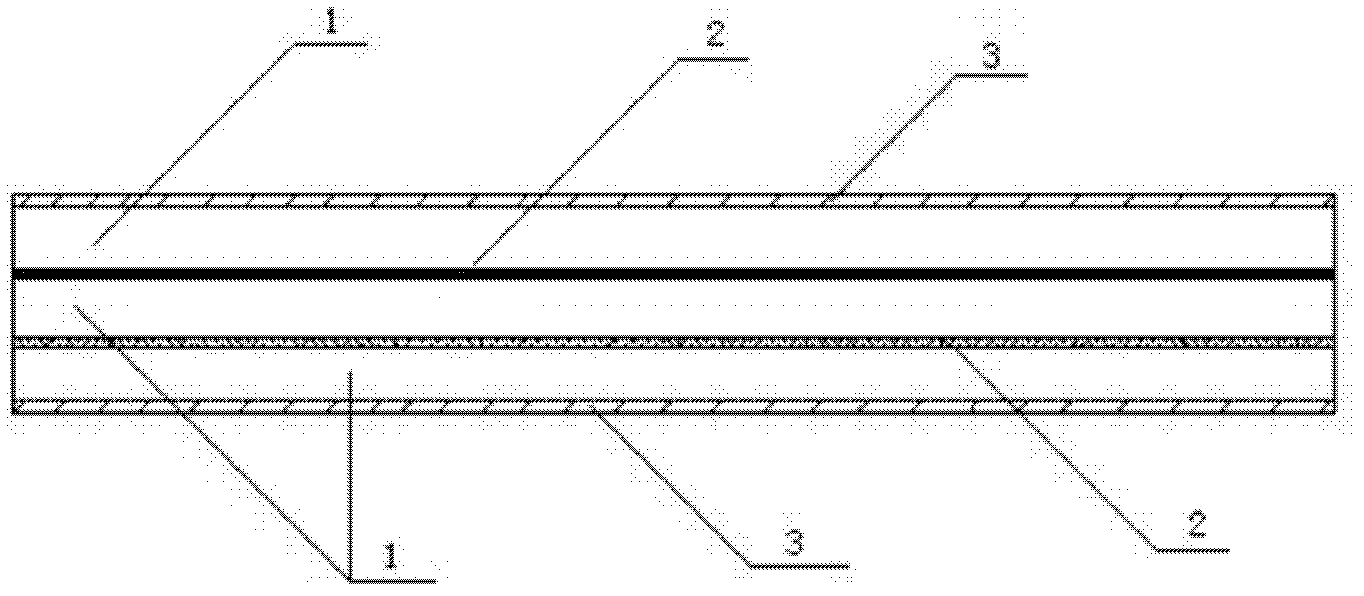

[0036] (3) Put the preheated raw material into the mold of the hot press machine, and lay 6.07kg of reinforcing fibers evenly in two layers in the raw material.

[0037] (4) Hot pressing, the pressure is 20MPa, the temperature is 200°C, and the time is 30min.

[0038] (5) Low temperature setting, the pressure is 20MPa, the temperature is 80°C, and the time is 15min.

[0039] (6) Carry out edge sawing and sanding on the prepared board, and paste a layer of fireproof surface layer on the upper and lower surfaces respectively to make a finished board of standard size.

[0040] Wherein the styrene-acrylonitrile copolymer foamed plastic waste powder is 20-100 mesh powder, and the reinforcing fib...

Embodiment 3

[0042] (1) Clean the styrene-acrylonitrile copolymer foam plastic waste, and then cut it into 0.5-2cm 3 block, and grind the block into 20-100 mesh powder.

[0043] (2) Weigh 38.25 kg of styrene-acrylonitrile copolymer foam plastic waste powder in (1) and preheat at 150° C. for 15 minutes.

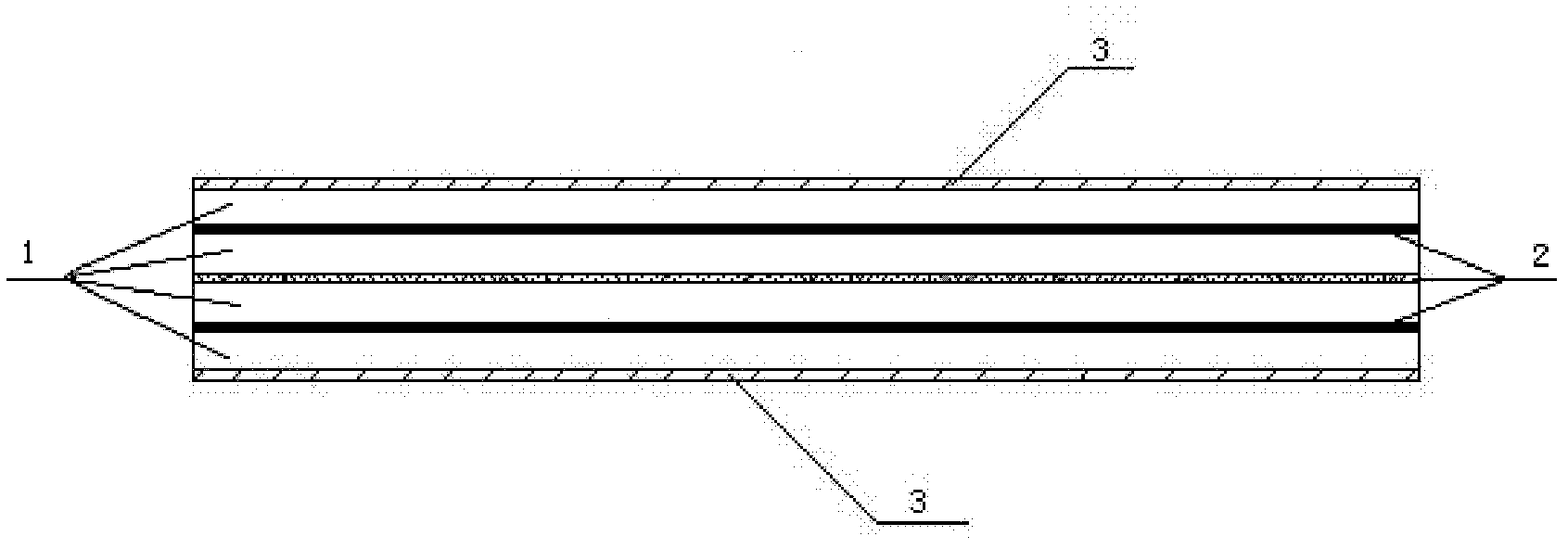

[0044] (3) Put the preheated raw material into the mold of the hot press machine, and evenly lay a layer of 6.07kg reinforcing fiber in the middle part of the raw material.

[0045] (4) Hot pressing, the pressure is 15MPa, the temperature is 180°C, and the time is 15min.

[0046] (5) Low temperature setting, the pressure is 10MPa, the temperature is 50°C, and the time is 10min.

[0047] (6) Carry out edge sawing and sanding on the prepared board, and paste a layer of fireproof surface layer on the upper and lower surfaces respectively to make a finished board of standard size.

[0048] The styrene-acrylonitrile copolymer foam plastic waste powder is 20-100 mesh powder, the reinforcing f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com