Cast-in-place concrete fire-proof thermal insulation compound external formwork and use method thereof

A fire-prevention and heat-preservation, concrete technology, applied in the directions of heat preservation, fire prevention, chemical instruments and methods, etc., can solve the problems of low strength and hardness, cracking and damage of protective layer, low compressive strength of thermal insulation materials, etc. The effect of high bond strength and comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

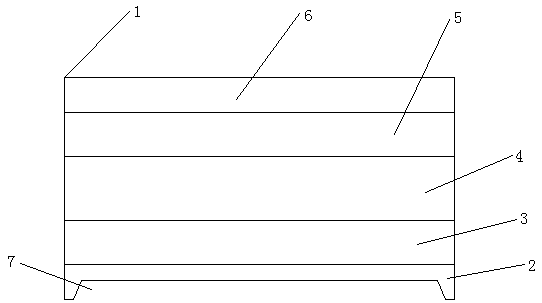

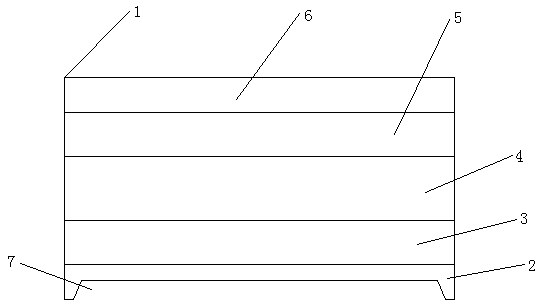

[0022] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

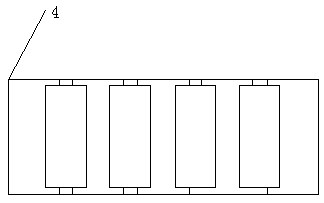

[0023] Such as Figure 1-2 As shown, it includes a board body 1, and the board body 1 is sequentially provided with an inner protective layer 2, an inner adhesive layer 3, a composite thermal insulation layer 4, an outer adhesive layer 5 and an outer protective layer 6 from the inside to the outside. The inner wall of the protective layer 2 is provided with a trapezoidal groove 7 that is connected with the concrete structure, and the inner surface of the inner protective layer 2 is connected with the concrete structure. In order to increase the reliability of the connection, when the concrete is poured, the cement paste is poured into the groove. After the concrete ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com