Glass ceramic table-board and its preparation method and application

A technology for glass-ceramic and countertops, applied in glass manufacturing equipment, glass furnace equipment, manufacturing tools, etc., can solve the problems of unsightly, not durable, unable to make glass-ceramic countertops, etc., and achieve good environmental performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

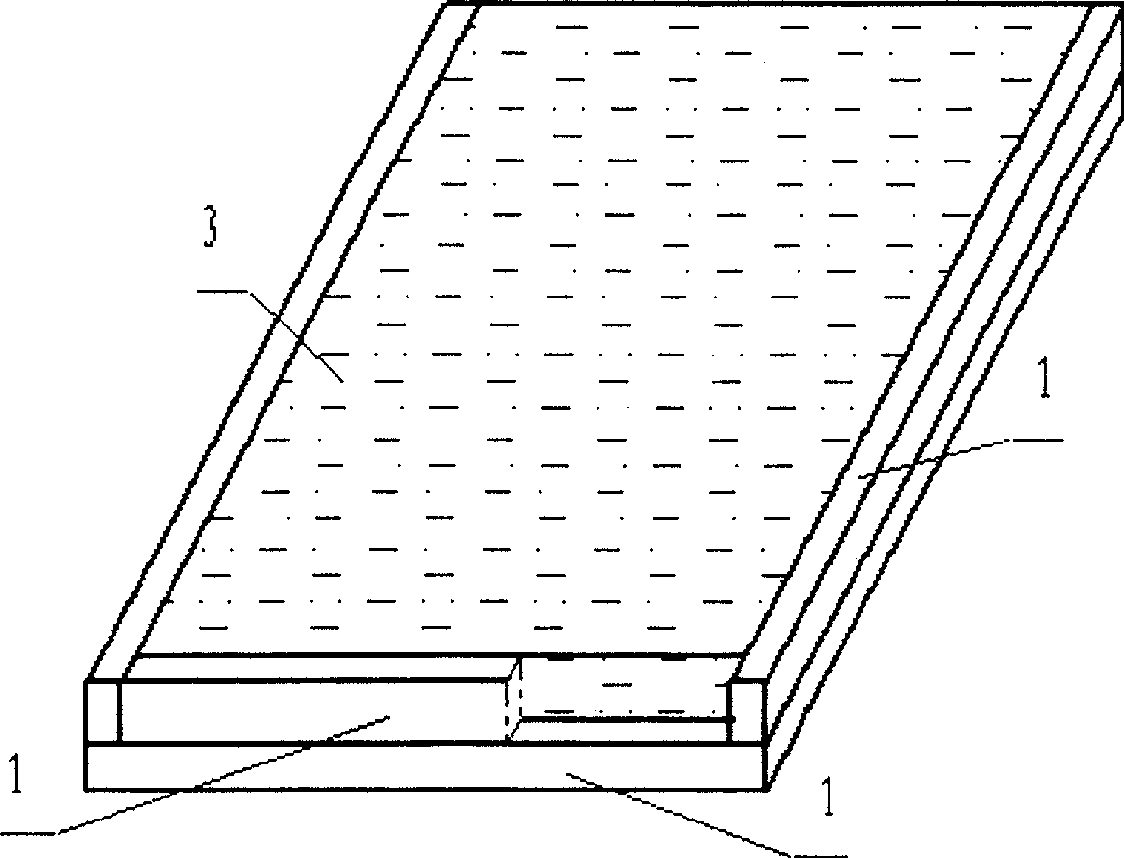

[0060] Embodiment 1: as figure 1 The shown glass-ceramic counter panel is prepared by the following method:

[0061] 1) The ingredients of the batch are as follows: 60 parts of quartz sand, 10 parts of limestone, 11 parts of dolomite, 12 parts of soda ash, 2 parts of iron oxide, and 2 parts of chromium oxide.

[0062] 2) the first sintering of glass pellets,

[0063] ①Provide a glass melting furnace and a glass pool furnace,

[0064] ② Send the batch material into the glass pool furnace and then send it to the glass melting furnace for melting. The melting temperature is 1300°C. After the glass solution is uniform in composition and the bubbles are clear, it is water-quenched into 1-5mm particle size. Dry to obtain glass pellets.

[0065] 3) Provide a barrier layer 1 according to the size of the required table top, which determines at least one surface critical layer of the glass pellets, the surface of the barrier layer 1 is covered with fire-resistant and anti-adhesive la...

Embodiment 2

[0070] The process of this embodiment is the same as that of Embodiment 1, only

[0071] The melting temperature of the first sintering is 1600°C;

[0072] The second sintering microcrystallization treatment temperature (i.e. holding temperature) is 1120°C for 50 minutes;

[0073] For the third sintering, the microcrystallization treatment temperature during sintering is 1136°C-1140°C, that is, the change of single crystallization temperature is controlled between 0°C-4°C, and the treatment time is 70 minutes.

Embodiment 3

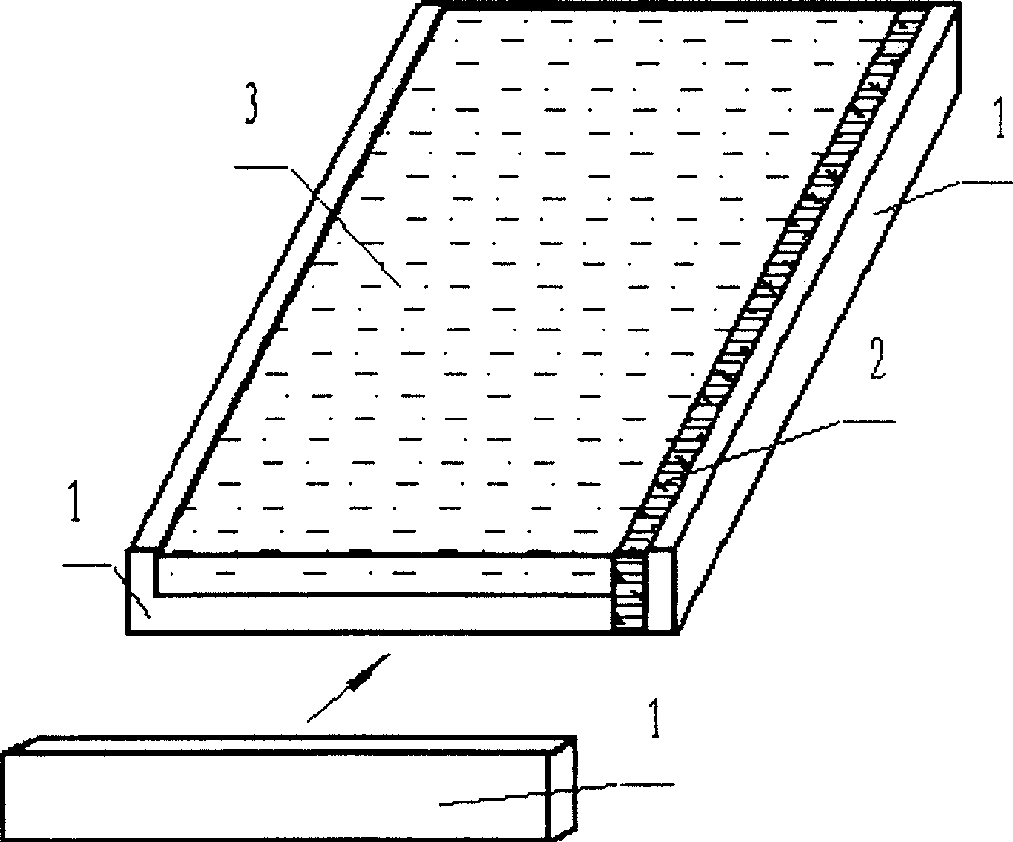

[0074] Embodiment 3: as figure 2 , image 3 The shown glass-ceramic cooktop panel is prepared by the following method:

[0075] 1) The ingredients of the batch are as follows: 60 parts of quartz sand, 10 parts of limestone, 11 parts of dolomite, 12 parts of soda ash, 2 parts of iron oxide, and 2 parts of chromium oxide.

[0076] 2) the first sintering of glass pellets,

[0077] ①Provide a glass melting furnace and a glass pool furnace,

[0078] ②Put the batch materials into the glass pool furnace and melt them in the glass melting furnace. The melting temperature is 1400°C. After the glass solution is uniform in composition and the bubbles are clear, it is quenched into 1-5mm particle size and baked. Dry to obtain glass pellets.

[0079] 3) Provide a barrier layer 1 according to the size of the required table top, which determines at least one surface critical layer of the glass pellets, the surface of the barrier layer 1 is covered with fire-resistant and anti-adhesive l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com