Film bulk acoustic resonator and manufacturing method thereof

A thin-film bulk acoustic wave and manufacturing method technology, applied in the direction of electrical components, impedance networks, etc., can solve the problems that cannot meet the requirements of high-performance radio frequency systems, and the quality factor of resonators cannot be further improved, so as to reduce longitudinal sound wave leakage and flatness Strong, lateral sound wave leakage improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

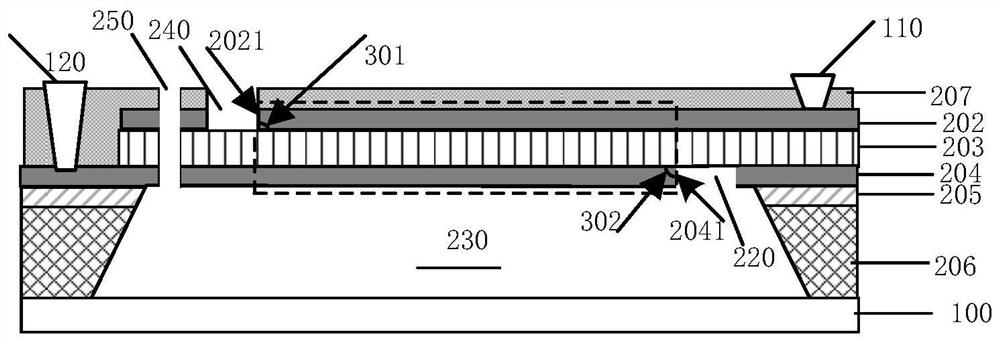

[0043] Embodiment 1 of the present invention provides a thin film bulk acoustic resonator, figure 1 It is a structural schematic diagram of the thin film bulk acoustic resonator of Embodiment 1 of the present invention, please refer to figure 1 , the thin film bulk acoustic resonator comprises:

[0044] a first substrate 100;

[0045] bonded to the support layer 206 on the first substrate 100, the support layer 206 is formed with a first cavity 230 penetrating through the support layer 206;

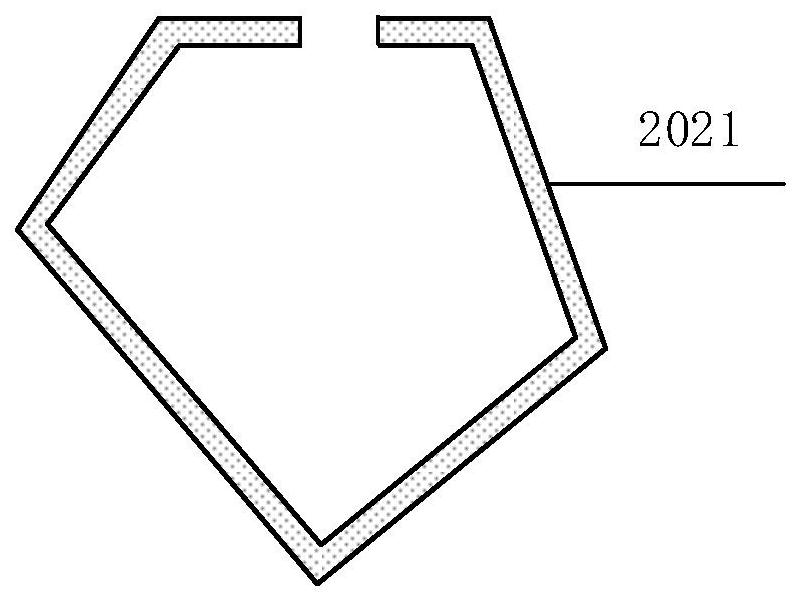

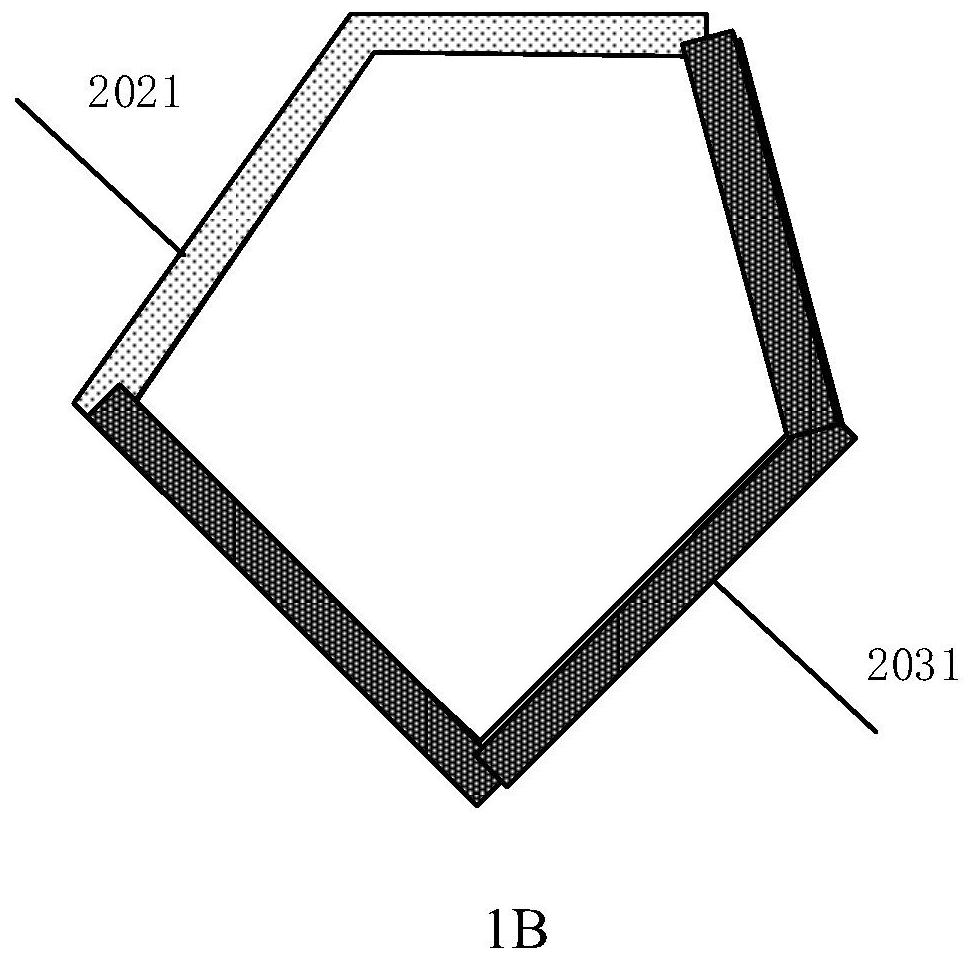

[0046] Piezoelectric stacked structure, covering the first cavity 230, the piezoelectric stacked structure includes sequentially stacked first electrode 202, piezoelectric layer 203 and second electrode 204 from top to bottom, in the effective resonance region ( Shown in the dashed box) the first electrode 202, the piezoelectric layer 203 and the second electrode 204 overlap in a direction perpendicular to the piezoelectric layer 203;

[0047] The first electrode 202 includes a first sid...

Embodiment 2

[0074] Figure 7 It is a structural schematic diagram of a thin film bulk acoustic resonator according to Embodiment 2 of the present invention.

[0075] The difference between embodiment 2 and embodiment 1 lies in that the first groove 240 and / or the second groove 220 penetrate at least a part of the thickness of the piezoelectric layer 203 . That is, the depth of the first trench 240 continues to extend down to the piezoelectric layer 203 (it may pass through the entire thickness of the piezoelectric layer 203 or end at a set depth of the piezoelectric layer 203 ) in addition to penetrating the first electrode 202 . The depth of the second trench 220 extends downwards to the piezoelectric layer 203 (it may run through the entire thickness of the piezoelectric layer 203 or may end at a predetermined depth of the piezoelectric layer 203 ) in addition to penetrating the second electrode 204 . Other structures are identical with embodiment 1, Figure 7 Only the structural diag...

Embodiment 3

[0077] Embodiment 3 of the present invention provides a method for manufacturing a thin film bulk acoustic resonator, the method comprising:

[0078] S01: providing a second substrate;

[0079] S02: forming a piezoelectric stack structure on the second substrate, the piezoelectric stack structure including a first electrode, a piezoelectric layer, and a second electrode sequentially formed on the second substrate;

[0080] S03: forming a support layer on the piezoelectric stack structure; forming a first cavity in the support layer, the first cavity passing through the support layer;

[0081] S04: providing a first substrate, bonding the first substrate on the support layer, the first substrate covering the first cavity;

[0082] S05: removing the second substrate; and

[0083] After the piezoelectric stack structure is formed, the piezoelectric stack structure is patterned to form an effective resonance area, and the boundary of the effective resonance area includes the fir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com