Producing method of rayon acrylic fiber yarn-dyed and blended fabric

A technology of blended fabrics and production methods, applied in the processing of textile materials, dyeing methods, fabric surface trimming, etc., can solve the problems of poor dyeing quality, low production efficiency, inaccurate colors, etc., achieve high color fastness and reduce manpower Cost and less hairiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

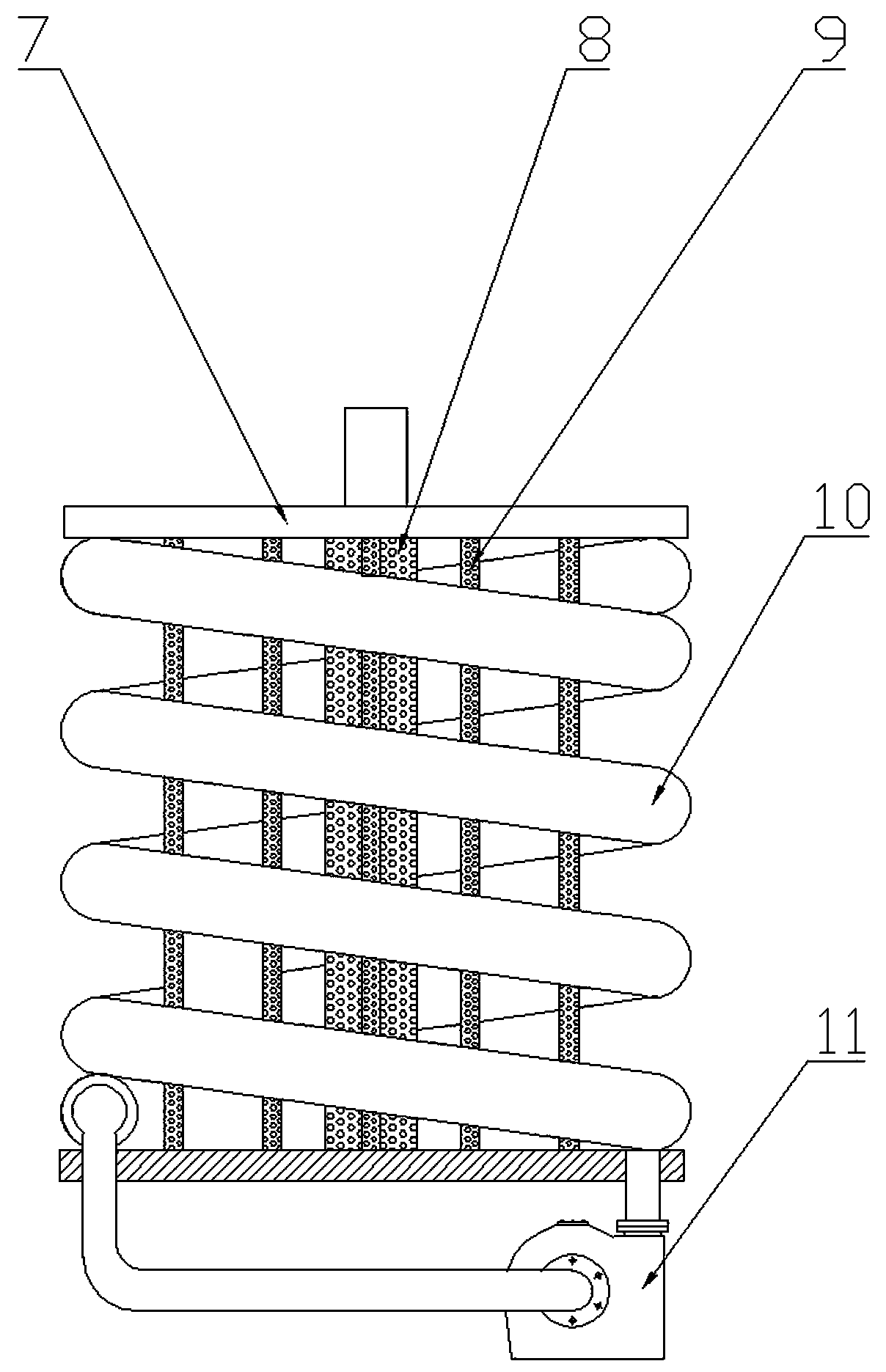

[0041] Example: such as Figure 1-8 Shown, a kind of production method of rayon-acrylic yarn-dyed blended fabric comprises loose yarn, pretreatment, blended dyeing, post-processing and finished product molding, and the production method of rayon-acrylic yarn-dyed blended fabric comprises the following steps:

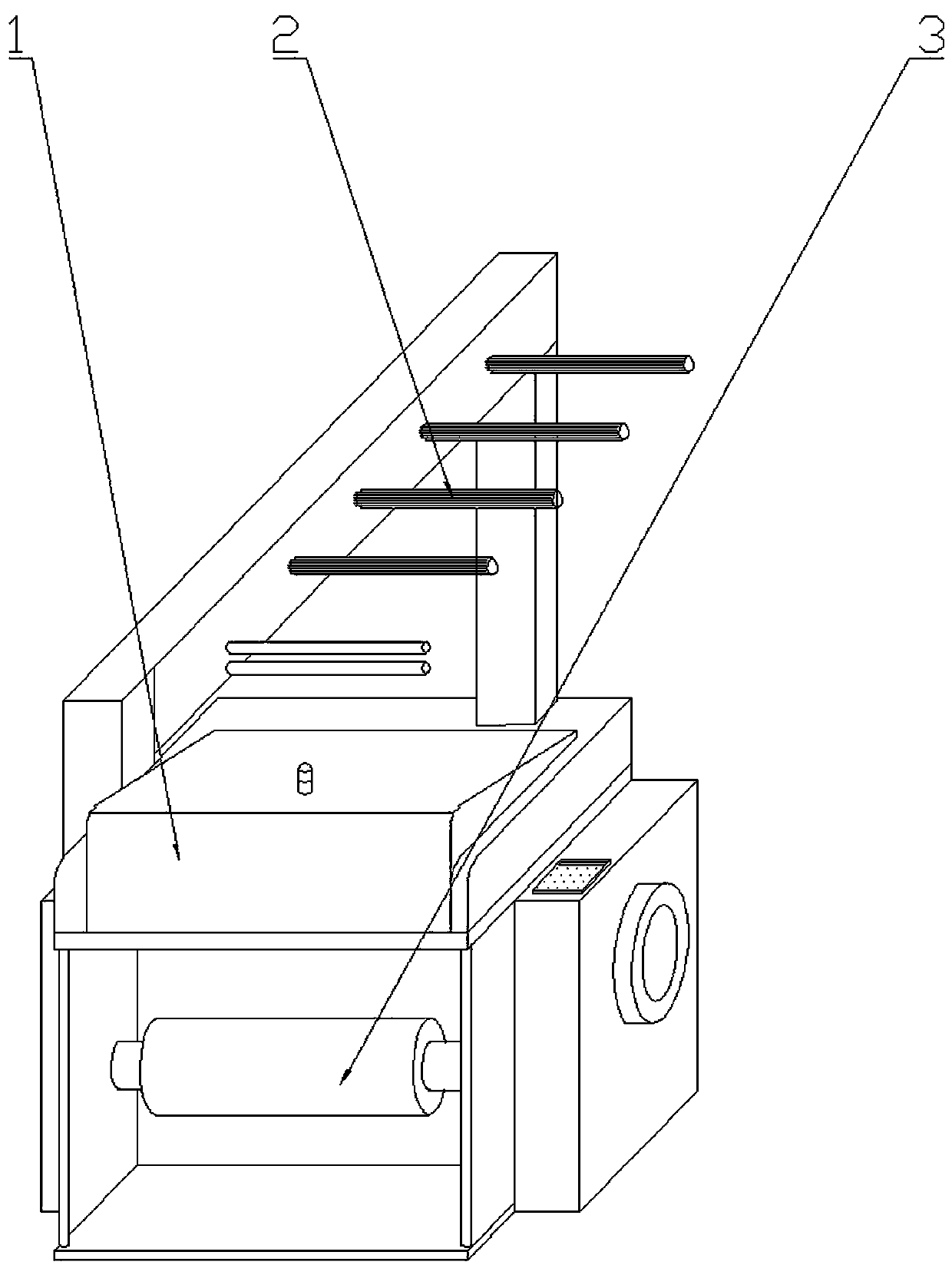

[0042] The first step: the loose yarn is to adopt the roller lead frame 2 to send the blended fiber yarn into the loose winding machine 1 to be processed into a loose yarn bobbin 3 .

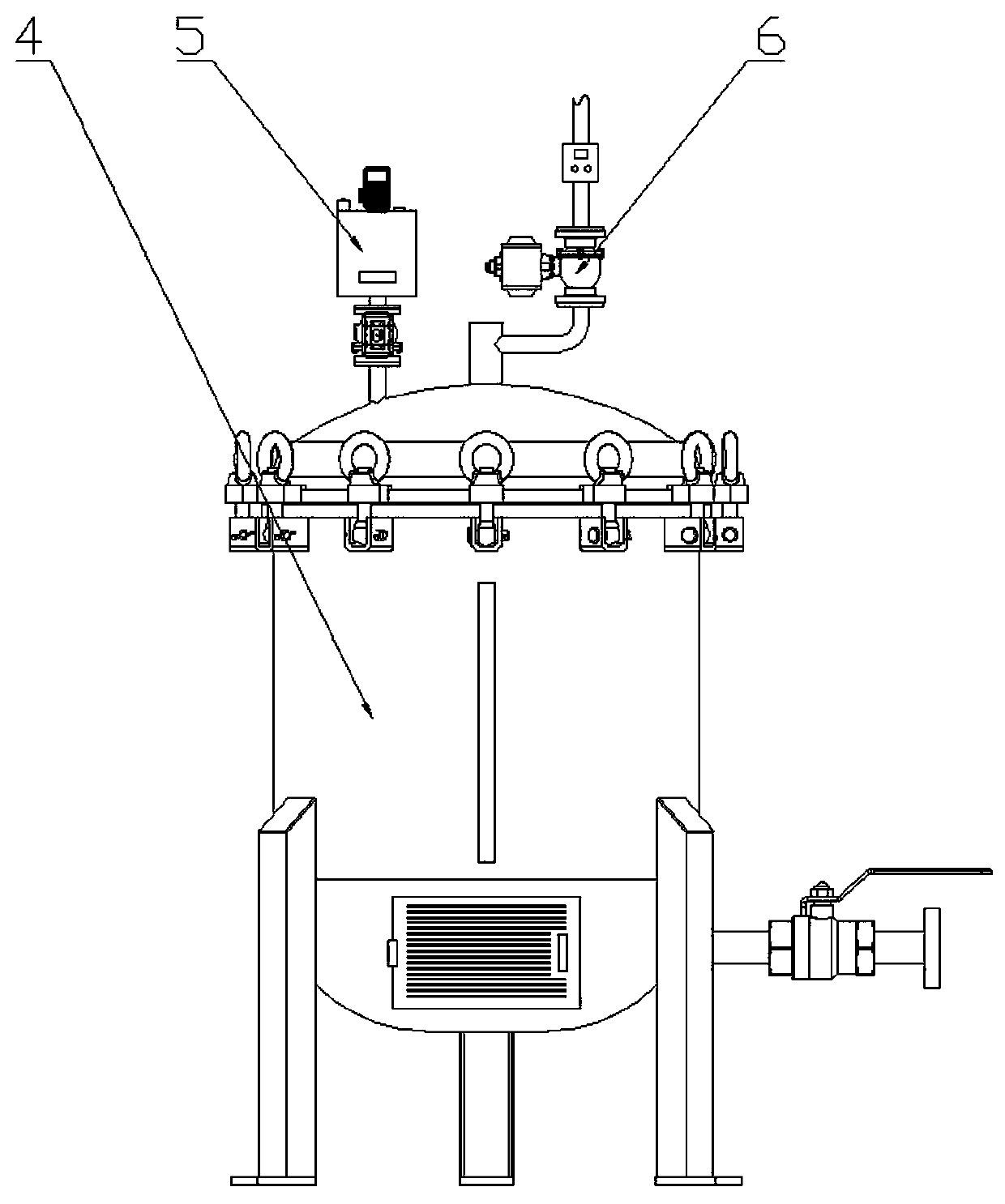

[0043] The second step: the pre-treatment is to place the yarn bobbin 3 in the bobbin dyeing device 4, add the refining agent and soda ash to the bobbin dyeing device 4 through the dye liquor adder 5, heat up to a high temperature and then keep warm . Then directly add cold water and acid after draining water through the water injection water temperature device 6 for processing. The pre-treated yarn package 3 discharges and recovers the liquid in the package dyeing device 4, and adds a b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com