Tearing and biting resisting optical cable and preparation method thereof

An optical cable and cable core technology, applied in the field of tear-resistant optical cable and its preparation, can solve the problems of poor adhesion of polyethylene sheath and poor strength of nylon 6 sheath, and achieve excellent sheath surface quality and good plasticizing effect. , The effect of enhanced tear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

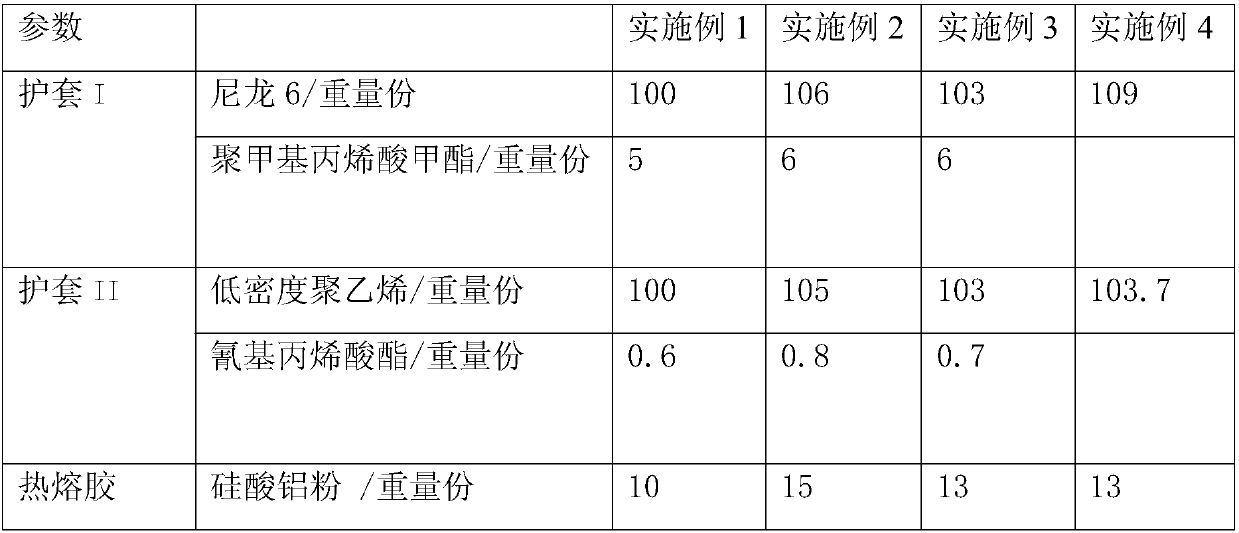

[0058] The technical solution of the present invention will be further described in detail below in conjunction with specific examples, but the protection scope of the present invention is not limited to the following description.

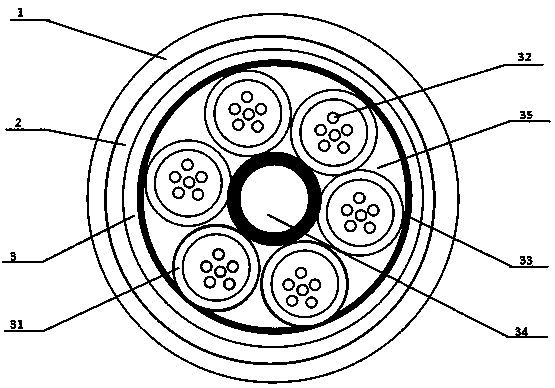

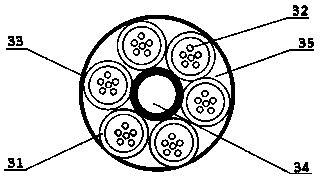

[0059] A tear-resistant optical cable, comprising a sheath I1, a sheath II2 is set inside the sheath I1, and a sheath III3 is set inside the sheath II2, and a hollow structure is formed inside the sheath III3 and at least one loose tube 31 is provided , each loose tube 31 is provided with at least 2n optical fibers 32 , wherein n is a positive integer, and 1≤n≤6.

[0060] Specifically, the sheath III 3 is a thickened steel strip.

[0061] Specifically, the surface of the sheath III 3 close to the loose tube 31 is covered with binding yarn 33, and the binding yarn 33 is a high-strength polyester yarn.

[0062] Specifically, a central reinforcement 34 and a cable core filler 35 are also arranged in the sheath III 3 .

[0063] A preparation method f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com