Hub temperature detecting and cooling control system

A technology for cooling control and wheel hubs, which is applied in the direction of cooling brakes, brake safety systems, brakes, etc., can solve problems such as hub stress cracks, brake failure, safety hazards, etc., and achieve the effect of avoiding sharp and large cooling and protecting the hubs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the present invention be further understood, the present invention will be further described below with reference to accompanying drawing and specific embodiment of description:

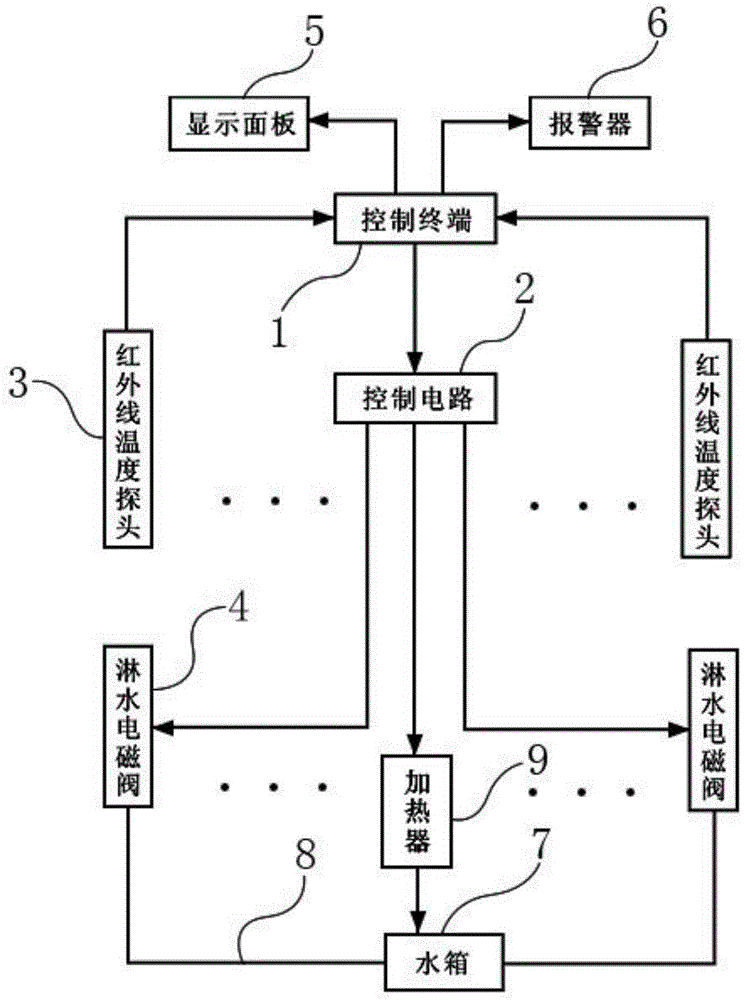

[0020] like figure 1 As shown, a wheel hub temperature detection and cooling control system includes a control terminal 1, a water tank 7, a water spray solenoid valve 4, and a temperature probe arranged at the wheel hub. The signal output end of the temperature probe is connected to the signal input end of the control terminal 1 , and the signal output end of the control terminal 1 is connected to the signal input end of the water spray solenoid valve 4 . Corresponding water delivery pipes 8 are provided between the water tank 7 and each wheel hub, and the water delivery pipes 8 are controlled on and off by the water spray solenoid valve 4 . Wherein, as an improvement of the present invention, the temperature probe is a non-contact temperature probe, specifically an infrared...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com