Pipe cutting, lifting and transporting integrated engineering van

A technology for pipe cutting and engineering vehicles, applied in metal processing, cranes, etc., can solve problems such as being unsuitable for use on construction sites, and achieve the effects of saving project costs, being convenient to use, and speeding up project progress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

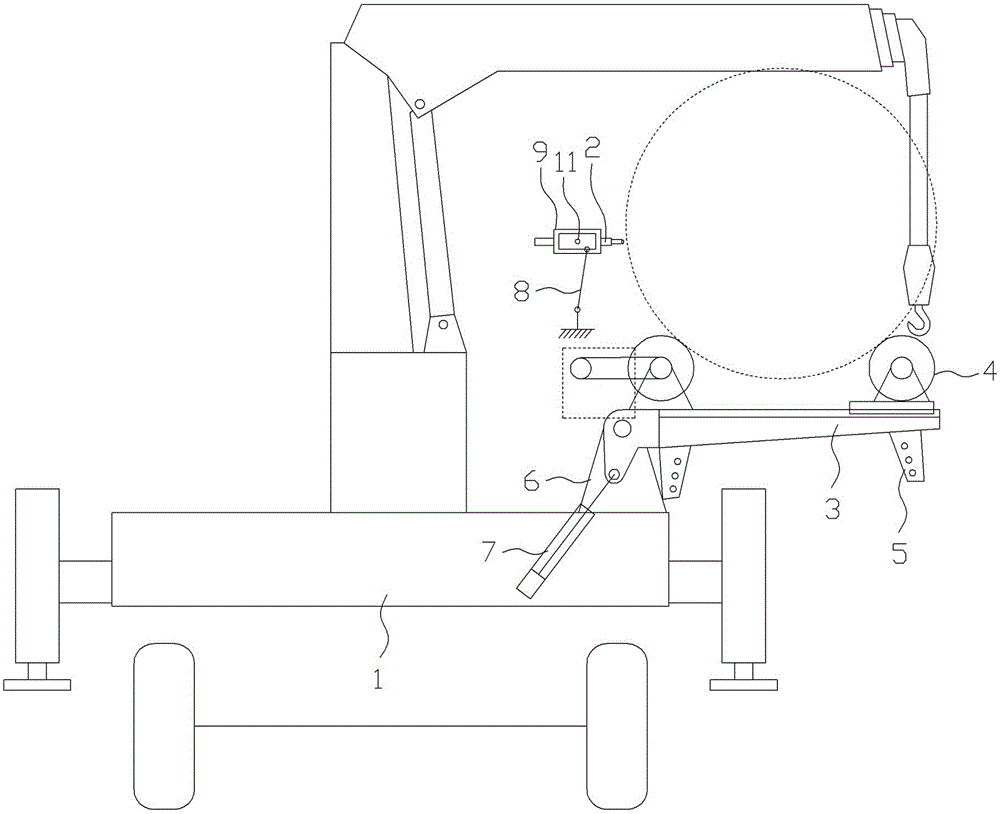

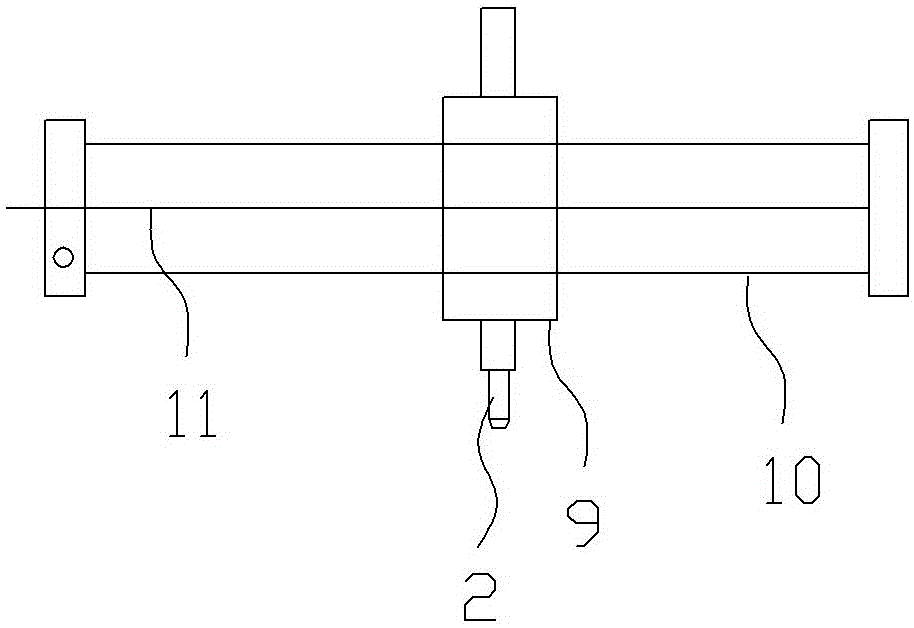

[0008] Such as figure 1 As shown, the pipeline cutting and lifting integrated engineering vehicle includes a crane chassis 1 provided with a lifting device and a pipeline cutter 2. The crane chassis 1 is provided with a pipeline carrier frame 3, and at least four The rollers 4 used to rotate the pipeline are arranged in a rectangle, and at least one of the rollers 4 is connected to the power device as a driving wheel. The other side of the pipeline carrier 3 is provided with a pipeline fixing device 5 for transporting pipelines. The seat 6 is hinged on the bearing surface of the crane chassis 1, the hinge seat 6 is fixed on one side edge of the crane chassis 1, and the pipe carrier 3 is connected with a turning hydraulic cylinder 7, and the pipe carrier 3 can be moved along the hinge axis through the turning hydraulic cylinder 7. Turn over to one side of the crane chassis 1 or withdraw to the bearing surface of the crane chassis 1, and the pipe cutter 2 is fixed on the bearing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com