A kind of preparation method of alkanolamine

A technology of alkyl alcohol amine and alkyl amine, which is applied in the field of preparation of alkyl alcohol amine, can solve the problems of increasing the difficulty of water separation, reducing the utilization rate of alkylene oxide, hydrolysis loss of alkylene oxide, etc., and achieves the raw material conversion rate and High recovery, high reactivity and selectivity, avoiding hydrolysis losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

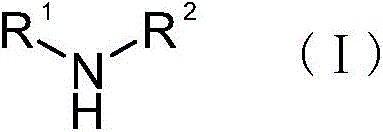

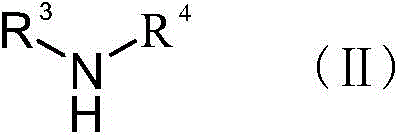

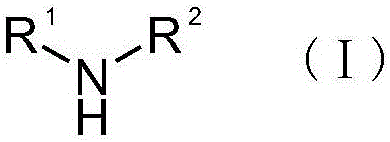

Method used

Image

Examples

Embodiment 1

[0035] 1. Add 105g of DEA and 45g of dimethylamine into the reaction kettle. After stirring evenly, add PO in four times with an interval of 10 minutes each time. A total of 63.8g of PO is added. After 3 hours, the material was discharged, and samples were taken for gas chromatography analysis. The conversion rate of dimethylamine was 95.2%, the yield of N,N-dimethylisopropanolamine was 94.4%, and the crude product color 4APHA was synthesized.

[0036] 2. Carry out continuous rectification of the crude product, the vacuum degree is -0.099MPa, the feed temperature is 100°C, the tower top cut-off temperature is 53°C, the purity of the refined N,N-dimethylisopropanolamine product is ≥99.5%, and the color The chromaticity is 0 APHA, the chromaticity is 6 APHA after 90 days at room temperature, and the chromaticity is 50 APHA after 7 days at 60°C.

[0037] 3. After the materials in the rectification column are passed into the reactor, analyze the amount of remaining DEA, add PO aga...

Embodiment 2

[0039] 1. Add 105g of DEA and 45g of dimethylamine into the reaction kettle. After stirring evenly, add PO in five times on average, with an interval of 8 minutes between each time, and a total of 92.8g of PO. Control the reaction temperature at 80°C, and the reaction pressure at 0.7MPa. After 2 hours, the material was discharged, and samples were taken for gas chromatography analysis. The conversion rate of dimethylamine was 99.2%, the yield of N,N-dimethylisopropanolamine was 98.9%, and the crude product color 6APHA was synthesized.

[0040] 2. Carry out continuous rectification of the crude product, the vacuum degree is -0.099MPa, the feed temperature is 100°C, the tower top cut-off temperature is 53°C, the purity of the refined N,N-dimethylisopropanolamine product is ≥99.5%, and the color The color is 0APHA, the color is 4APHA after being placed at room temperature for 90 days, and the color is 57APHA after being placed at 60°C for seven days.

[0041] 3. After the materials...

Embodiment 3

[0043] 1. Add 105g of DEA and 45g of dimethylamine into the reaction kettle. After stirring evenly, add PO in five times on average, with an interval of 7 minutes between each time. A total of 104.4g of PO is added. The reaction temperature is controlled at 60°C, and the reaction pressure is 0.7MPa. After 3 hours, the material was discharged, and samples were taken for gas chromatography analysis. The conversion rate of dimethylamine was 98.7%, the yield of N,N-dimethylisopropanolamine was 98.1%, and the crude product was synthesized with a color of 8APHA.

[0044] 2. Carry out continuous rectification of the crude product, the vacuum degree is -0.099MPa, the feed temperature is 100°C, the tower top cut-off temperature is 53°C, the purity of the refined N,N-dimethylisopropanolamine product is ≥99.5%, and the color The chromaticity is 0 APHA, the chromaticity is 10 APHA after 90 days at room temperature, and the chromaticity is 70 APHA after 7 days at 60°C.

[0045] 3. After th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com