Scrap steel preheating-type heating furnace for steel production conducted through medium-frequency electric furnace

A technology for intermediate frequency electric furnaces and heating furnaces, which is applied in the direction of electric furnaces, furnaces, furnace types, etc., and can solve the problems of reducing electric energy consumption, etc., and achieve the effects of reducing flue gas volume, increasing productivity, and cheap prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

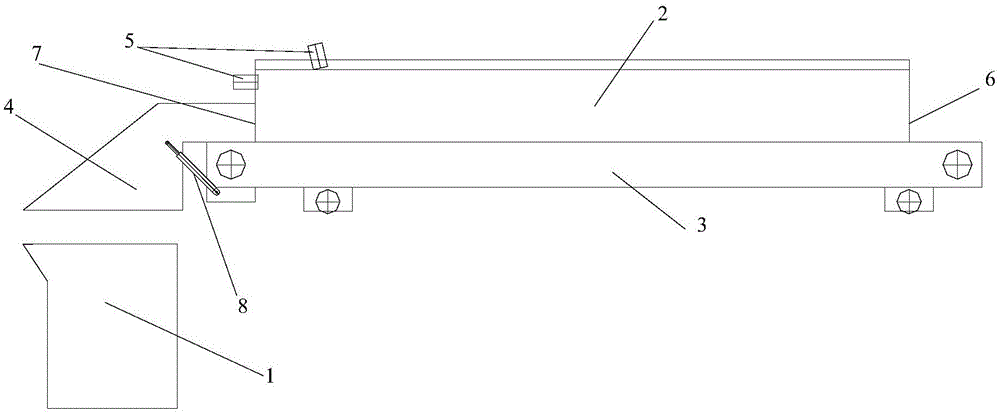

[0024] Below in conjunction with accompanying drawing, the present invention is further described:

[0025] A scrap steel preheating heating furnace for intermediate frequency electric furnace steelmaking, comprising an intermediate frequency electric furnace 1, a heating furnace body 2, a conveying device 3, and a reflow hood 4, the conveying device 3 is arranged below the heating furnace body 2, Both sides of the heating furnace body 2 are respectively provided with a feed inlet 6 and a discharge outlet 7 , and the reflow hood 4 is supported and installed on the side of the heating furnace body 2 through a hydraulic cylinder 8 .

[0026] One end of the reflow hood 4 communicates with the discharge port 7 , and the other end is arranged directly above the intermediate frequency electric furnace 1 .

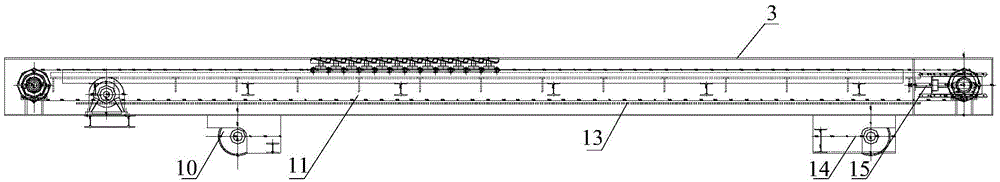

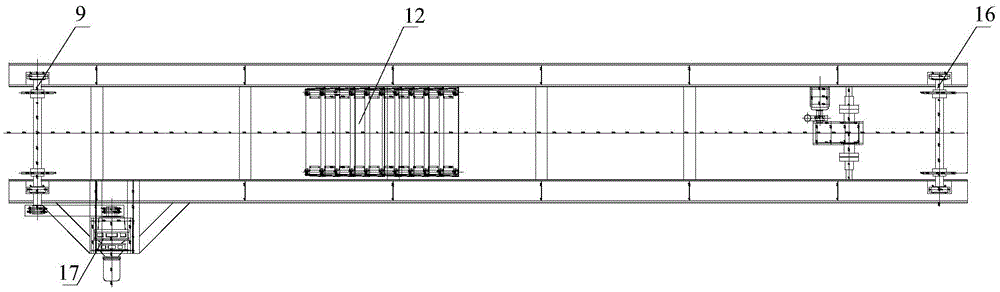

[0027] The transmission device 3 includes a frame 11, a chain plate 12, a conveying chain 13, a tensioning device 15, and a cycloidal pinwheel reducer 17, and the two ends of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com