Cantilever Casting Arch Bridge Hanging Basket Push-up Crawler Small Tank Walking Method

A technology for small tanks and arch bridges, applied in bridges, buildings, bridge construction, etc., can solve the problems of low operation efficiency of hanging baskets, reduce friction, etc., and achieve the effect of reducing frequent switching, improving mobility, and small labor input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

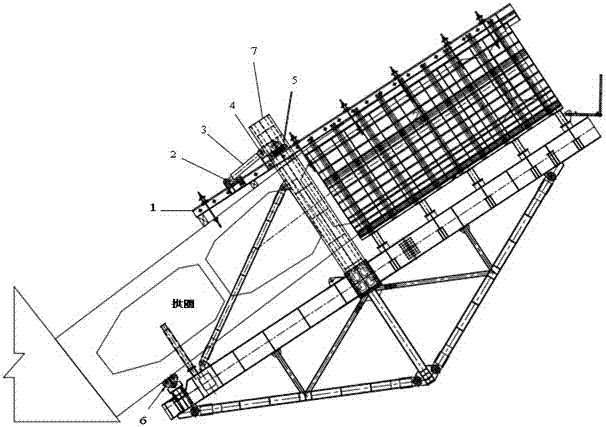

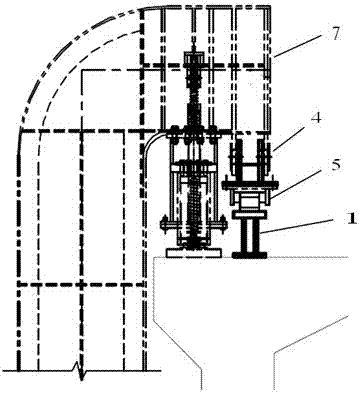

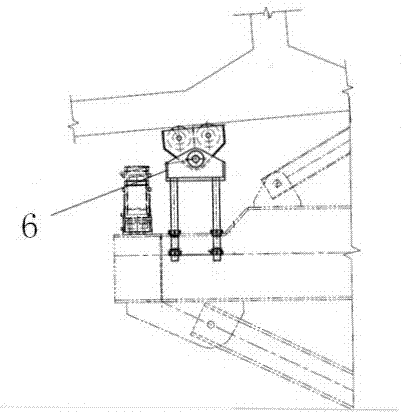

[0028] The main structure of the walking system of the present invention is mainly composed of a walking track 1, a rear pulley 6, a small crawler tank 5, a hydraulic jack 3, front and rear supports of the jack, and a hanging basket. The tracked small tank 5 is also called the crawler type handling small tank under the trade name.

[0029] The hanging basket of the cantilever pouring arch bridge chooses the down-loaded inverted triangle hanging basket. The overall structure of the hanging basket is on the lower side of the concrete structure. A small crawler tank 5 is designed and installed on the hanging leg 7, and the front support 4 of the jack is set on the hanging leg 7 of the hanging basket. and be connected with the hydraulic jack 3, and the rear pulley 6 is set at the rear fulcrum of the main beam of the hanging basket. Utilize the effective combination of the continuous jack and the track to push the tracked small tank to realize the walking of the hanging basket.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com