Support replacing construction structure and method for rapidly demounting first support of large foundation trench

A construction method and foundation pit technology, which is applied in the direction of basic structure engineering, excavation, construction, etc., to achieve the effect of simple process and convenient control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

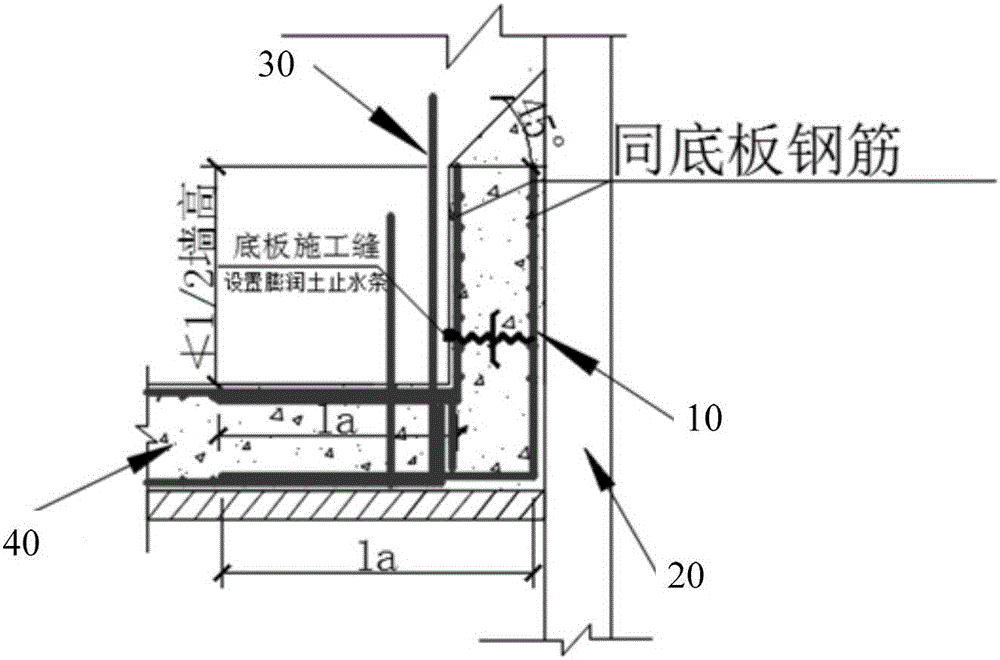

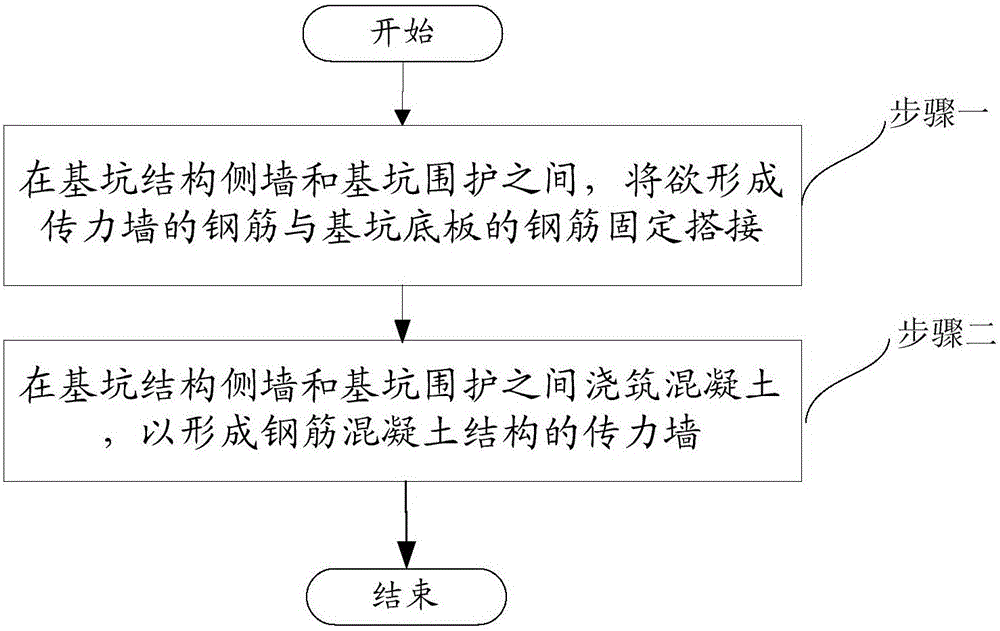

[0034] The application will be described in further detail below in conjunction with the accompanying drawings.

[0035] In the prior art, after removing the first support in a large foundation pit, it is necessary to set up replacement braces. The conventional method of brace replacement mainly adopts steel braces, or uses the structural side wall as a force transmission back brace. The steel braces need to be placed on the floor surface. The support corbels are left on the top, and an additional step of chiseling the concrete pier is required when the support is removed and replaced later. However, the conventional process of using the structural side wall as the form of brace replacement will cause problems in the protection of the finished wall in the process of reserving the waterproof joints of the side wall openings and removing the concrete support in the future. Nowadays, the structural forms of large spaces are mostly in the form of The form of steel structure and co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com