Variable-diameter back reaming device and process method

A reverse reaming and variable-diameter technology, applied in drilling equipment and methods, earthwork drilling, drilling equipment, etc., can solve the problems of large outer diameter of the stabilizer, high risk of stuck pipe, low efficiency, etc., to ensure reliable High performance, smooth movement, and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

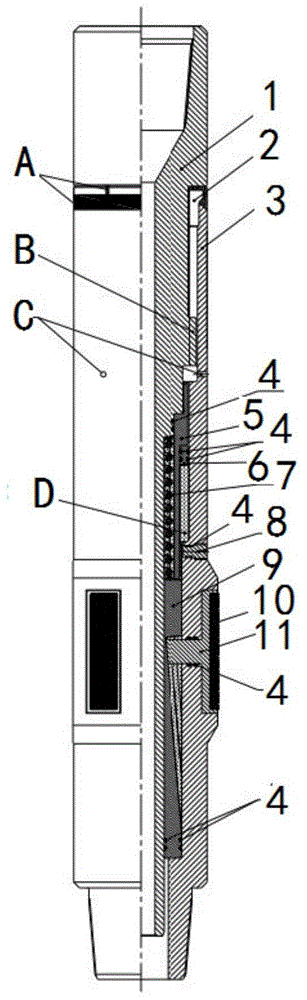

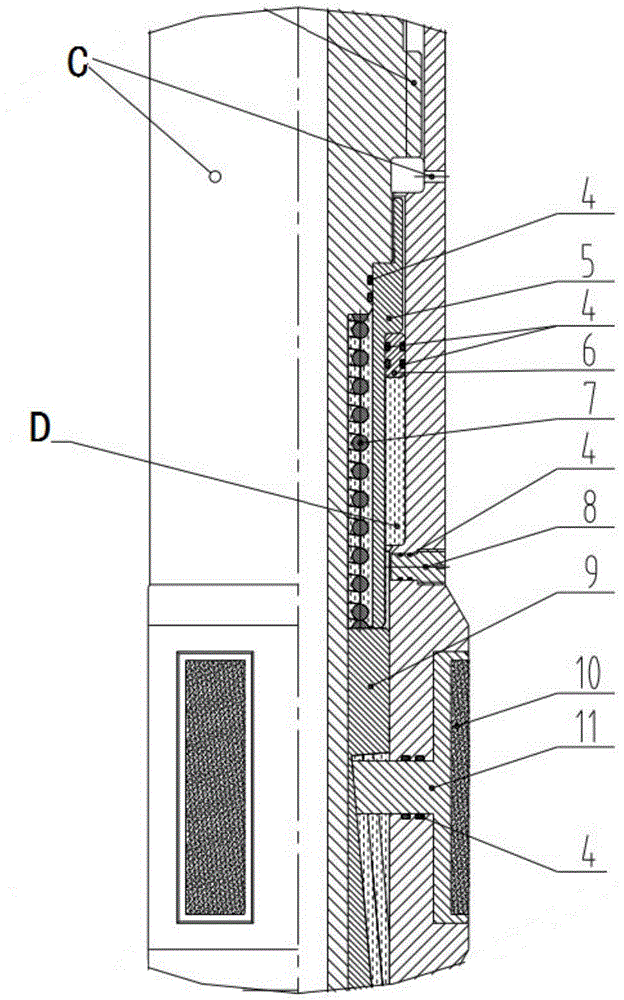

[0048] Embodiment 1: as figure 1 , figure 2 , image 3 with Figure 4 As shown, a variable diameter reamer, the central rod 1 and the body 3 are connected by a spline pair B, the body 3 has a through hole C, the upper part of the body 3 is provided with a load-bearing end cover 2, and the middle part of the body 3 is 3 Ridge or 4-rib structure, 2 oil injection holes are arranged symmetrically above the rib and an oil filling plug 8 is installed, and a cutting block 11 is arranged on each rib; the annular space between the center rod 1 and the body 3 is equipped with a balance piston rod 5 and a balance piston 6. The spring 7, the inclined cylinder 9, the balance piston rod 5 is connected with the center rod 1 through threads, the balance piston 6 is installed in the ring space between the balance piston rod 5 and the body 3, and the spring 7 is installed between the balance piston rod 5 and the center rod 1 between.

[0049] The specific implementation process of the pres...

Embodiment 2

[0063] Embodiment 2: as figure 1 , figure 2 , image 3 with Figure 4 As shown, a variable diameter reamer includes a central rod, a load-bearing end cover, a body, a balance piston rod, a balance piston, a spring, an oil plug, an inclined cylinder, and a cutting block. The center rod 1 and the body 3 Connect and form an annulus, the annulus is provided with a balance piston rod 5, a balance piston 6, a spring 7, and an inclined cylinder 9, the balance piston rod 5 is connected with the center rod 1, and the incline cylinder 9 is placed at the lower part of the balance piston rod 5. A spring 7 is arranged in the annular space formed by the piston rod 5 and the central rod 1, a balance piston 6 is set on the balance piston rod 5, and a through hole C is opened on the body 3, and the through hole C is respectively connected with the upper cavity of the balance piston rod 5 and The well wall annulus is connected.

[0064] A preferred embodiment of the present invention is th...

Embodiment 3

[0074] Embodiment 3: as figure 1 , figure 2 , image 3 with Figure 4 As shown, a variable diameter reamer includes a center rod 1, a load-bearing end cover 2, a body 3, a sealing ring 4, a balance piston rod 5, a balance piston 6, a spring 7, an oil plug 8, and a bevel cylinder 9 , Cemented carbide block 10, cutting block 11, etc. The central rod 1 and the body 3 are connected by a spline pair B, the body 3 has a through hole C, the upper part of the body 3 is provided with a load-bearing end cover 2, the middle part of the body 3 is a structure of 3 to 4 ribs, and two oil injection holes are arranged symmetrically above the ribs Hole and install oil injection plug 8, each edge is provided with cutting block 11, on the cutting block, cemented carbide block 10 is inlaid. The annulus between the center rod 1 and the body 3 is equipped with a balance piston rod 5, a balance piston 6, a spring 7, and an inclined plane cylinder 9. The balance piston rod 5 is connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com