Axial Forced Magnetic Suspension Bearing

A technology of magnetic suspension bearings and axial force, applied in the direction of shafts and bearings, bearings, mechanical equipment, etc., can solve the problems of reduced sensitivity of rotating mechanisms, reduced detection accuracy of flow rate meters, high manufacturing costs and maintenance costs, and achieve significant technological progress , Improved rotation sensitivity and reduced maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings.

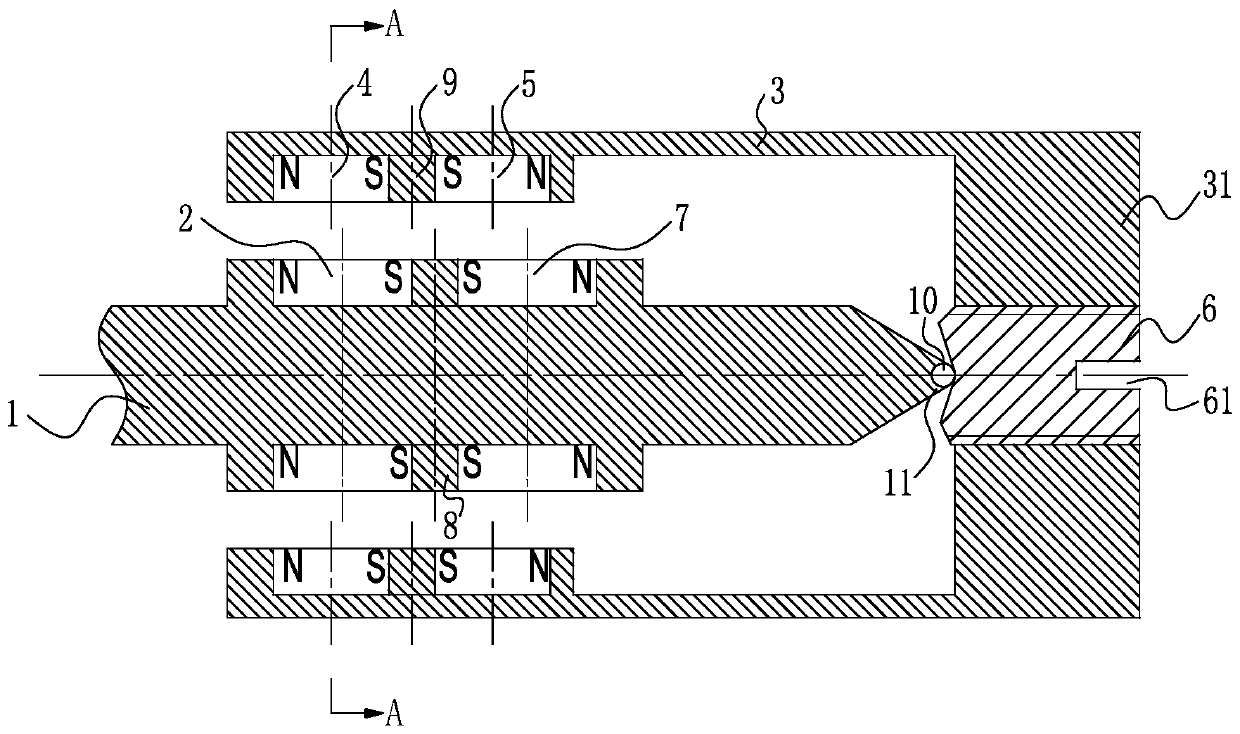

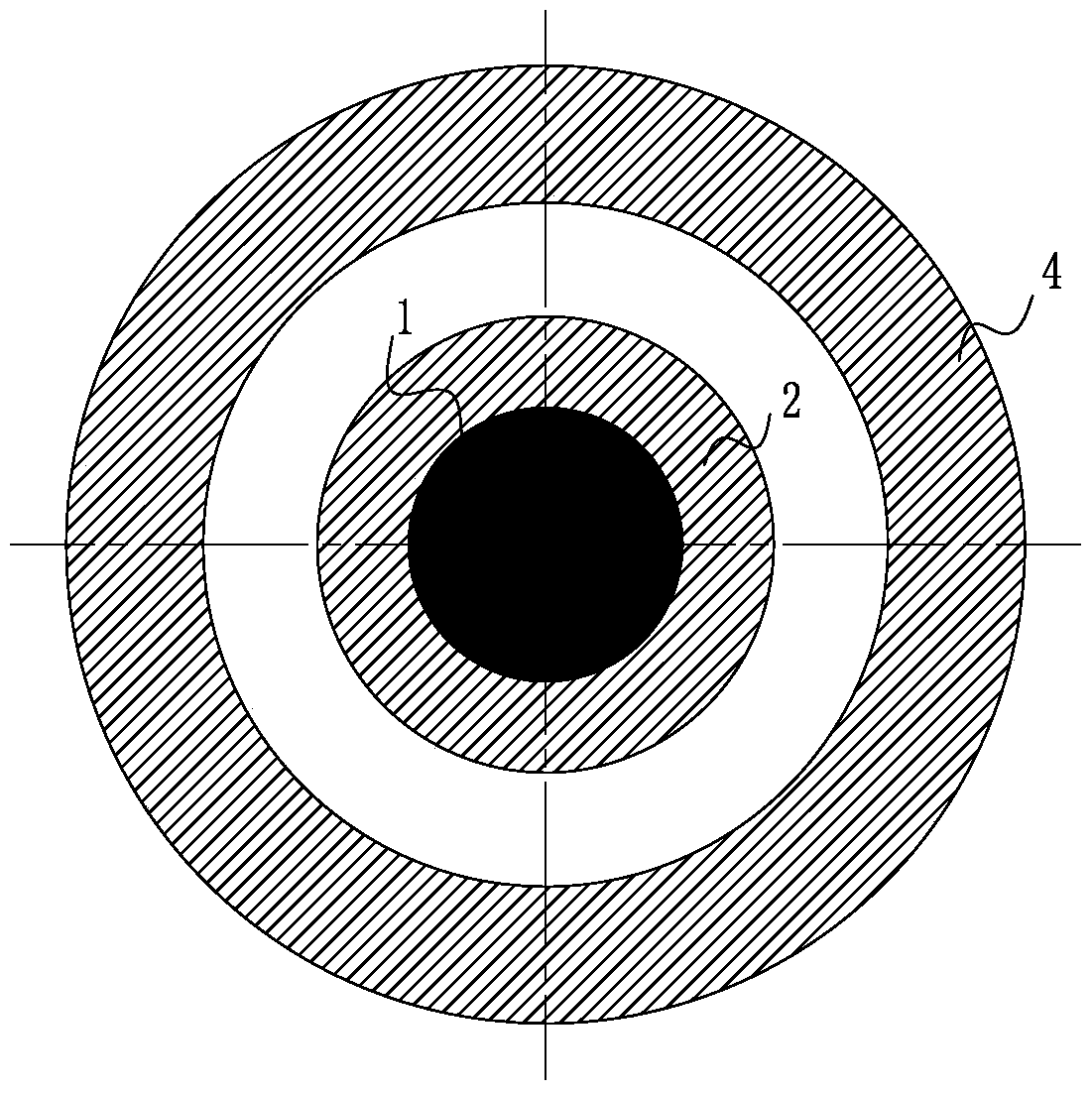

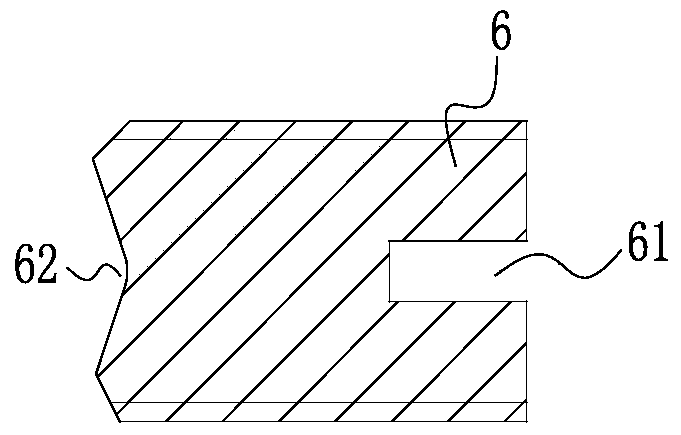

[0017] a kind of like Figure 1-Figure 3 The axially stressed magnetic suspension bearing shown includes a shaft core 1, on which a first inner magnetic ring 2 and a second inner magnetic ring 7 on the same centerline as the shaft core 1 are arranged side by side, and the shaft core 1 The outer spacer sleeve is provided with a shaft sleeve 3, that is, there is a certain distance between the shaft core 1 and the shaft sleeve 3, the shaft sleeve 3 includes a base 31, and one end of the shaft core 1 is provided with a top 11 located on the center line of the shaft core 1, The top 11 leans against the center of the base 31, and the sleeve 3 is provided side by side with the first outer magnetic ring 4 and the second outer magnetic ring 5 respectively corresponding to the first inner magnetic ring 2 and the second inner magnetic ring 7. The i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com