Overflow-free internally piloted valve

A self-control valve and liquid overflow technology, which is applied to the valve details, valve device, valve shell structure, etc., can solve the problems of shortened service life, failure to close once closed, fragility, etc., and achieve accurate and reliable performance, installation safety protection, and use convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

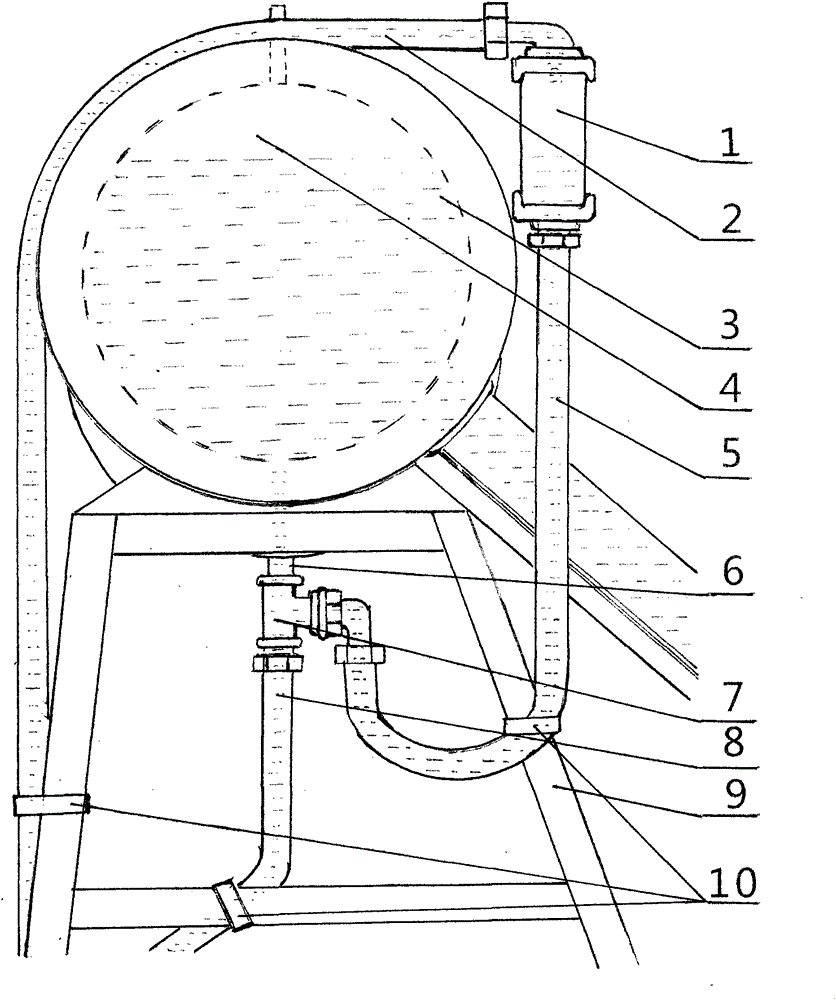

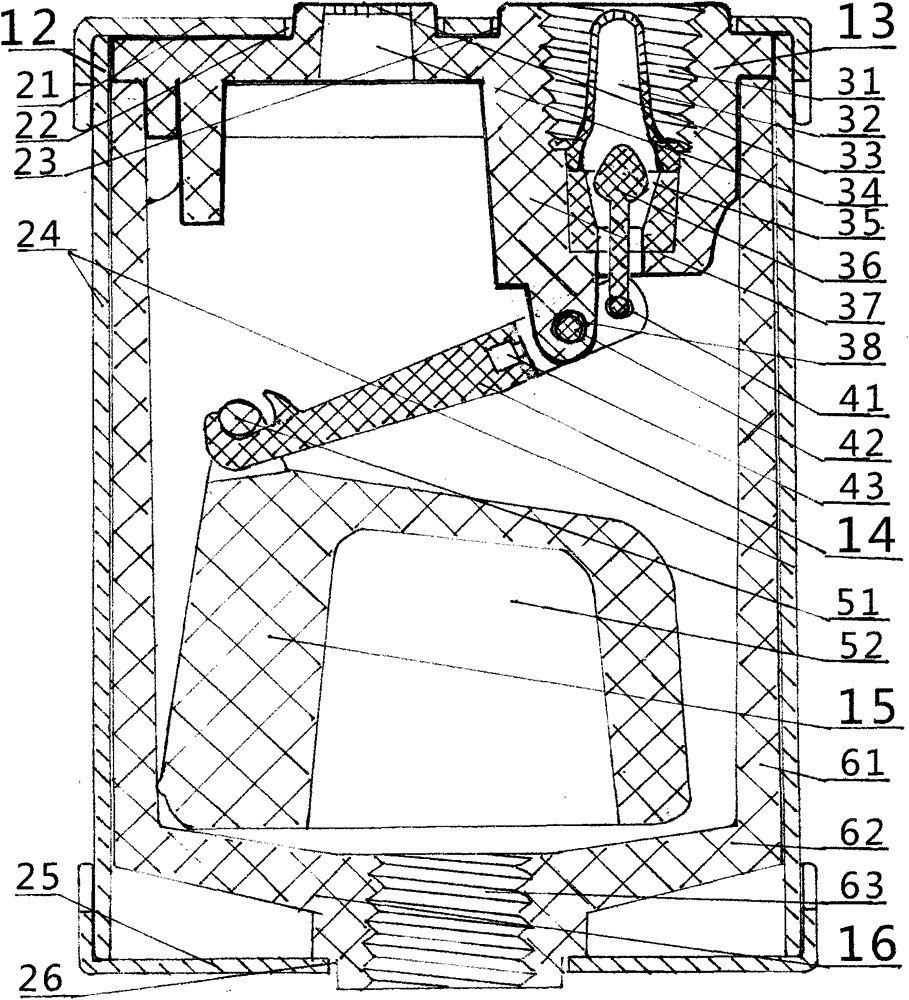

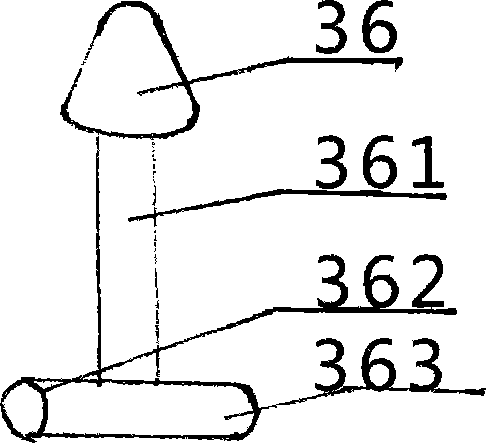

[0021] see Figure 1-Figure 6 , make protective cover (21), protective pipe (24), bottom protection (25) with punching press, method of pulling gold. The valve body (13), the valve handle (14), the floating body (15), the liquid reservoir (16), the strainer pipe (32), and the valve port (35) are made of non-toxic, heat-resistant and frost-resistant high-quality material by injection molding and glue pressing , valve plug (36), valve handle cover (431), and strictly check the quality of each accessory. Put the valve port (35) and valve plug (36) into the valve body (13), the shaft (42) of the valve handle (14) extends into the shaft hole (38), and the right end of the plug shaft (362) is inserted into the head hole (41) , the cover head hole (432) is set on the left end of the plug rotating shaft (363), the cover rotating shaft hole (433) is positioned and connected with the rotating shaft (42) head, the cover double hook (434) is fixedly connected with the double hook hole (4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com