Reducing two-way pipe joint and reducing two-way pipe joint component

A technology for connecting pipes and components, applied in the direction of pipes/pipe joints/fittings, passing elements, hose connection devices, etc., which can solve problems such as damage, large locking force, and hose deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

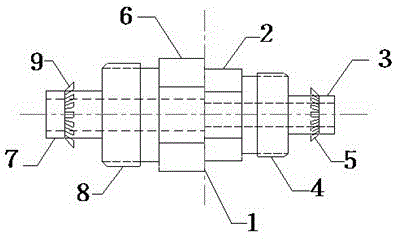

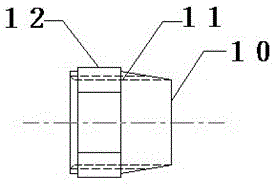

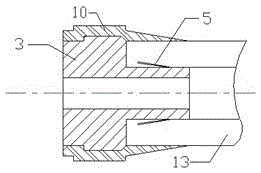

[0018] Embodiments of the variable diameter two-way pipe joint assembly of the present invention are as Figure 1-3 As shown: the small-diameter fastening nut 10 and the large-diameter fastening nut for locking the trachea include two-way pipe joints with variable diameters and two structures. The main body 1 of the two vent joints of the through-hole reducing pipe and the small-diameter connecting pipe sleeve 3 and the large-diameter connecting pipe sleeve 7 located at both ends of the main body 1, the diameter of the small-diameter connecting pipe sleeve 3 is smaller than the large-diameter connecting pipe sleeve 7 The diameter of the small-diameter connecting pipe sleeve 3 and the large-diameter connecting pipe sleeve 7 are respectively provided with a small-diameter interface and a large-diameter interface, and also includes two small-diameter fastening nuts with different sizes for matching with the small-diameter connecting pipe sleeve 3 10 and the large-diameter fasteni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com