Separation mechanism for battery piece sintering furnace and using method of separation mechanism

A technology for sintering furnaces and cells, applied in furnaces, furnace components, charge manipulation, etc., can solve the problems of energy waste, increase production costs, fast heat dissipation of sintering furnaces, etc., and achieve the effects of reducing production costs and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

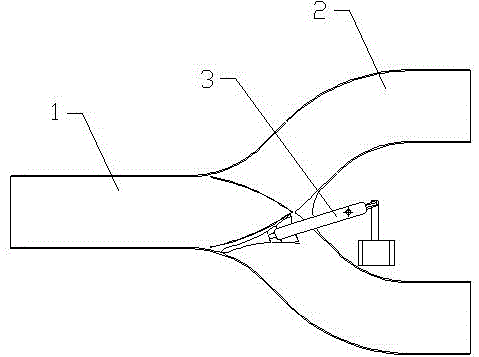

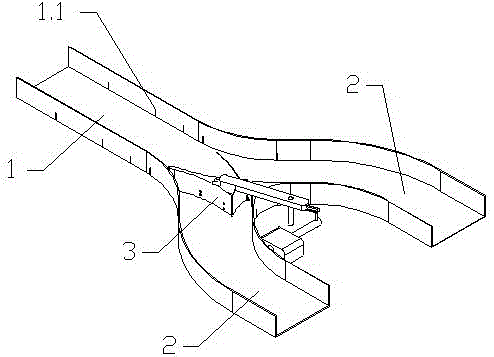

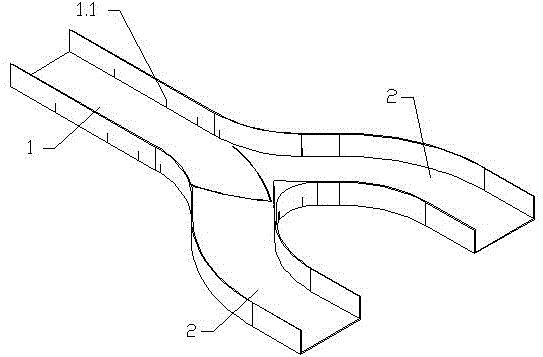

[0019] see Figure 1~Figure 4 , the invention relates to a lane-dividing mechanism for cell sintering furnaces, which includes a group of feeding sections 1, two groups of symmetrically arranged feeding sections 2 and a feeding mechanism 3, the front end of the feeding section is connected to the sintering furnace The feed port of the sintering channel, the rear end of the material distribution section is connected to the discharge port of the sintering channel of the sintering furnace, and the material receiving section 1 includes a material receiving guide groove and a material receiving and conveying roller at the bottom of the material receiving guide groove, so There are multiple sets of first material sensors 1.1 arranged on the inner walls of both sides of the material distribution guide chute from front to back, and the first material sensor 1.1 includes a signal transmitting end located on one side of the material distribution guide The signal receiving end on the oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com