Airtightness detection system through differential pressure

A detection system and tightness technology, applied in the detection field, can solve problems affecting product reliability, economy, harmful gas overflow, loss, etc., and achieve high precision, improved detection speed, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

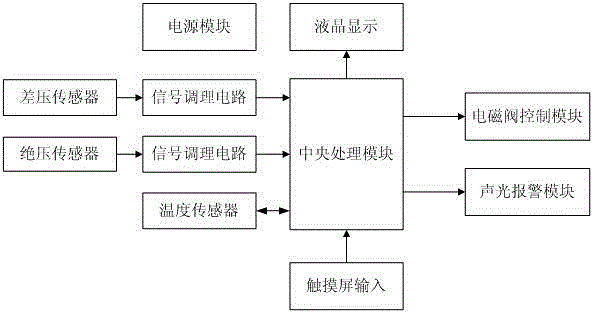

[0009] refer to figure 1 , is a differential pressure air tightness detection system, including a central processing module, a data acquisition module, a signal conditioning module, a solenoid valve control module, an audible and visual alarm module, a power supply module and a human-computer interaction module, and the data acquisition module collects After the signal is processed by the signal conditioning module, it is sent to the central processing module for processing. The solenoid valve control module controls the automatic opening and closing of the solenoid valve through the instructions of the central processing module. The sound and light alarm module is connected to the central processing module. The power supply module supplies power to the whole system, and the human-computer interaction module controls the input and output of the system.

[0010] The central processing module is the control center of the entire system. Its main function is to realize the switch ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com