Sliding-model control method for compensating a model uncertainty of a direct drive motor system

An uncertain, direct drive motor technology, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve the problems of not being able to obtain high-precision control performance, stimulating high-frequency dynamics of the system, and adding controllers , to achieve the effects of ensuring transient control performance, reducing gain, and eliminating observation errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

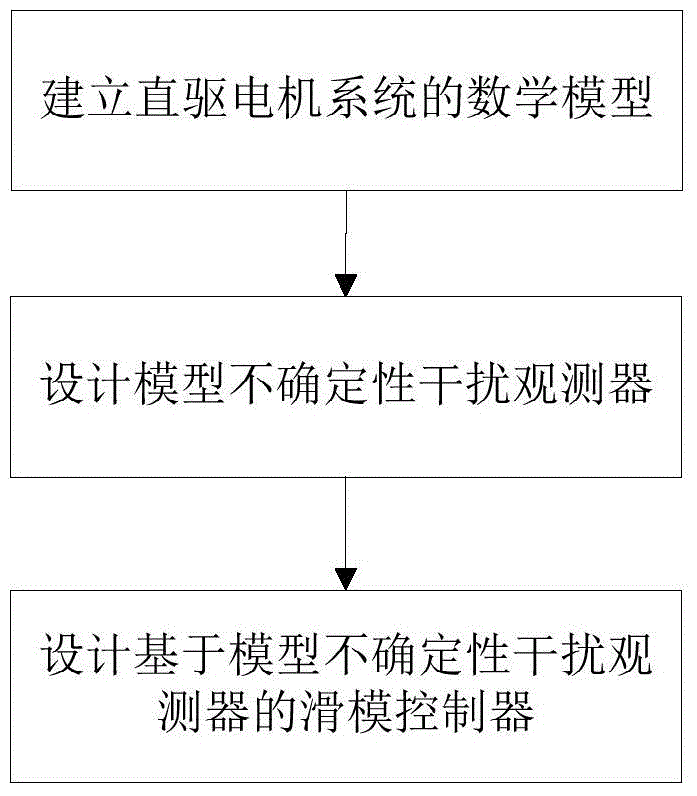

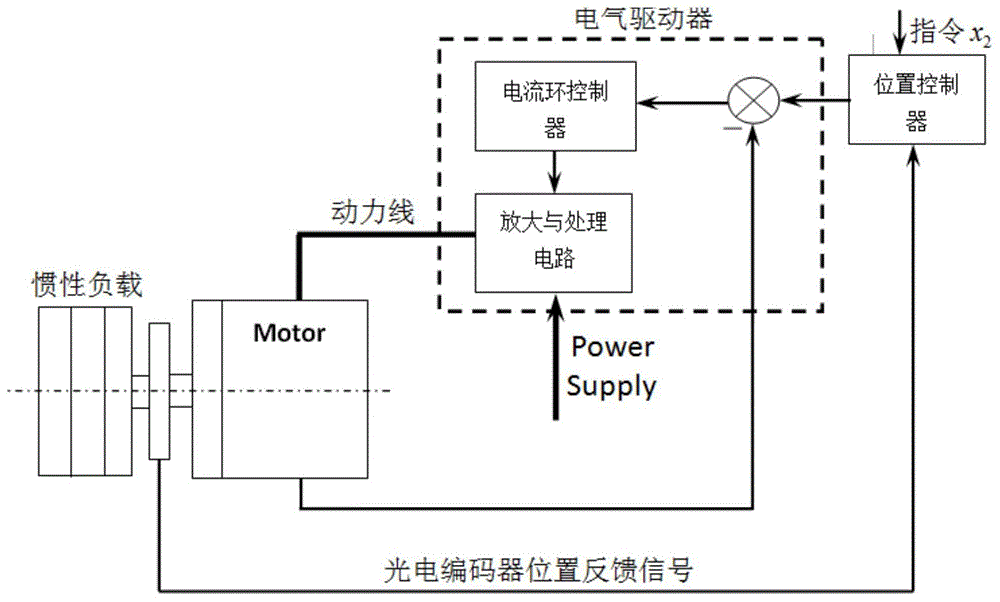

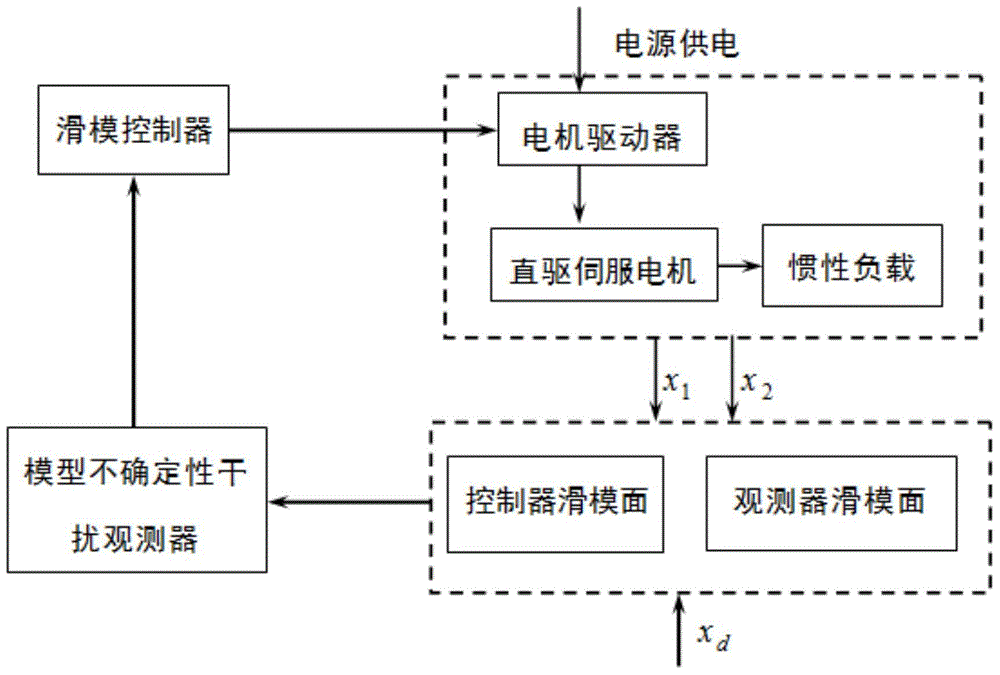

Method used

Image

Examples

Embodiment

[0094] In order to assess the performance of the designed controller, the following parameters are taken in the simulation to model the direct drive motor system:

[0095] Inertia load parameter m=0.0138kg m 2 ; Viscous friction coefficient B = 0.2N m s / rad; Moment amplification factor k u =53.6N·m / V;

[0096] The desired instruction for a given system is: x d =8sin(t)[1-exp(-0.01t 3 )](rad)

[0097] According to two different system working conditions, the simulation process is divided into two parts:

[0098] 1) When the model uncertainty d(x,t)=0.3+0.1sin(πt)N m:

[0099] Take the following controller for comparison:

[0100] Model Uncertainty Compensated Sliding Mode Control (UC‐SMC) controller: take the model uncertainty observer parameter k 1 =5000, β 1 =30,ε 1 =0.05,p 1 = 3 and q 1 =5; controller parameter c 1 =512,c 2 = 192, k = 0.001.

[0101] Sliding mode controller (SMC): In order to force the system state to reach the sliding mode surface, the selecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com