Automatic viscosity regulating apparatus during material stirring

A technology of automatic adjustment and electric control valve, applied in the direction of valve operation/release device, valve device, mixer accessories, etc., can solve the problems of reducing production efficiency, consuming labor workload, affecting drug production, etc., reducing workload, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Taking the preparation of levosimendan intermediate as an example, the levosimendan intermediate is made of distilled water, zinc powder, and 3-(4-acetylaminobenzoyl)-butenoic acid as raw materials, put into a reaction vessel, and stir promote its chemical reaction. Wherein, the amount of each component raw material is as follows: distilled water is 1000ml, zinc powder is 82.82g, and 3-(4 acetamidobenzoyl)-butenoic acid is 125g.

[0041] During the stirred reaction process of the levosimendan intermediate, its Isothermal viscosity-time curve Such as image 3 As shown, the viscosity value is 4.2 when the raw materials of each component just start to stir (the temperature is 10°), and when the stirring is carried out for 20 minutes, the viscosity value is 4.3, and the viscosity value has an upward trend, representing the degree of reaction , when stirring for 100 minutes, the viscosity value is 4.5, and the change of the viscosity value tends to be stable, which means ...

Embodiment 2

[0045] Taking the preparation of levosimendan intermediate as an example, the levosimendan intermediate is made of distilled water, zinc powder, and 3-(4-acetylaminobenzoyl)-butenoic acid as raw materials, put into a reaction vessel, and stir promote its chemical reaction. Wherein, the amount of each component raw material is as follows: distilled water is 1000ml, zinc powder is 82.82g, and 3-(4 acetamidobenzoyl)-butenoic acid is 125g.

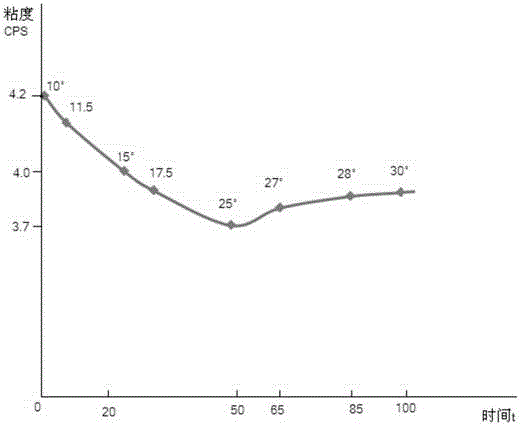

[0046] In the preparation process of levosimendan, the temperature of the stirring device is often controlled to speed up the reaction. Therefore, for the stirring process where the temperature is also changing, the viscosity change follows the variable temperature viscosity-time change curve, such as Figure 4 Shown, wherein when each component raw material just begins to stir (the temperature is 10 °), the viscosity value is 4.2, when stirring is carried out to 20 minutes (the temperature is 15 °), the viscosity value is 4.0, there is a down...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com