Hand-operated type multi-tooth-form drawing machine

A hand-operated, drawing machine technology, applied in the direction of non-circular curve plotters, simulators, mechanical equipment, etc., can solve the problems of unimaginable fanfare, reduce the interest of experimenters, and the cumbersome and lengthy process of drawing teeth, etc., to achieve enhanced understanding , Easy to operate, increase the effect of interest

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with specific embodiment, the present invention is further described:

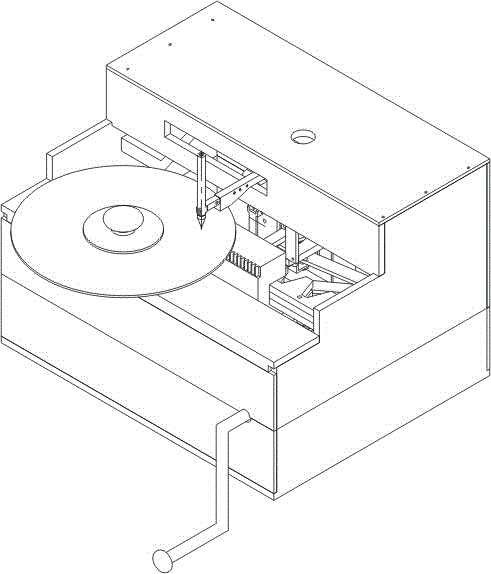

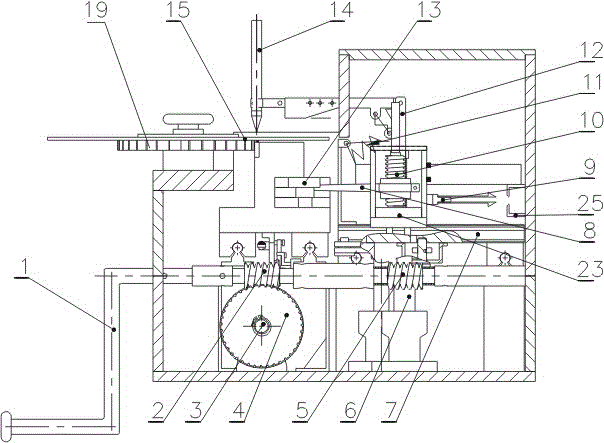

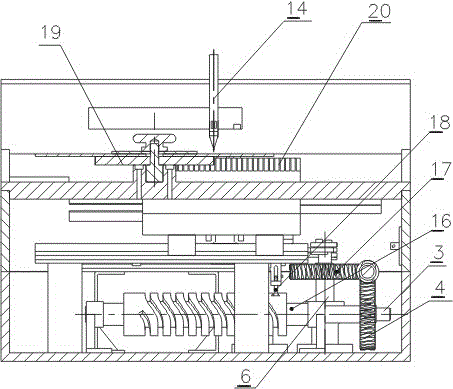

[0022] Such as figure 1 figure 2 image 3 Figure 4 The shown hand-operated multi-toothed plotter includes a worm shaft 1 on which a first worm 2 and a second worm 5 are respectively connected to the first worm 4 and the second worm 17, and synchronized Drive the first rotating shaft 3 and the second rotating shaft 6 to rotate, wherein the first rotating shaft 3 is connected to the four-bar linkage mechanism 22 through the crank 21 for reciprocating motion, and a space cam 16 is installed on the second rotating shaft 6; the space cam 16 is a spiral Groove structure, the cam follower pin 18 is stuck in the groove, and the cam follower pin 18 can move along the groove; the cam follower pin 18 connects the rack cutter 13 and the rack 20, and the rack 20 is connected and driven by the gear 19 Animation tooth disk 15 moves; Described four-bar linkage mechanism 22 connects and dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com