Method for repairing core of rack transformer

A transformer, bench type technology, applied in switchgear, electrical components, cranes, etc., can solve the problems of high labor cost, long maintenance time, long working time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific embodiment of the present invention is:

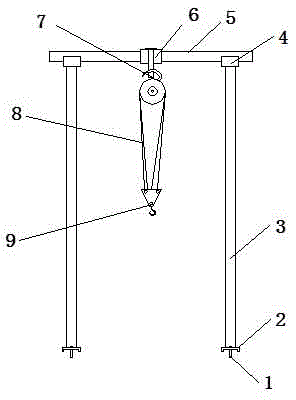

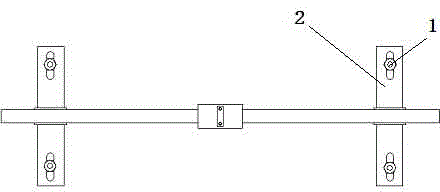

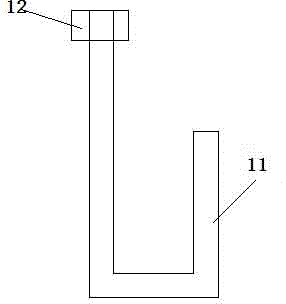

[0023] (1) Special equipment for installing and maintaining the hanging core on the channel steel at the bottom of the bench-type transformer; the special equipment is a door-shaped bracket hanging core tool, including a bracket, a chain hoist 7, and a lifting piece 9. The bracket includes a The base plate 2 connected with the transformer channel steel, the fixing element 1, the column 3, and the beam 5; the base plate 2 is 700 mm long and 100 mm wide, fixed on the lower end of the column 3, and is provided with a long hole suitable for the transformer channel steel, There are two long holes, 100mm in length and 20mm in width, which are used to adjust and adapt to different types of transformers; the fixing element 1 is a hook-shaped element with a diameter of 16mm at one end and a width of 85mm. 190mm, the length of the short side of the hook is 110mm, the hook is used to hang the channel steel on the transformer, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com