Method for remote speed regulation of stepping motor

A stepper motor, long-distance technology, applied in the direction of motor generator control, electrical components, control systems, etc., can solve the problems of increasing control lines and poor anti-interference ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] Hereinafter, the present invention will be further described in detail with reference to the accompanying drawings and embodiments, but the embodiments of the present invention are not limited thereto.

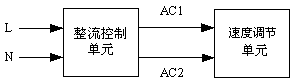

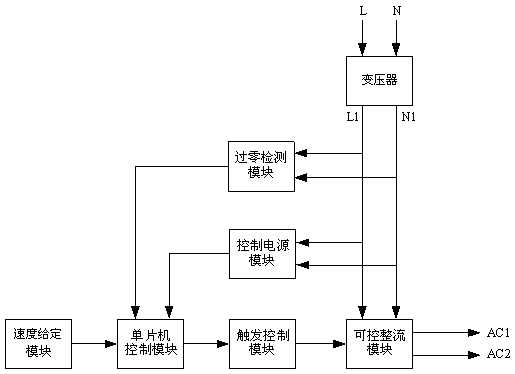

[0073] The system structure block diagram of the method and device of the present invention is as follows figure 1 As shown, it consists of a rectification control unit and a speed adjustment unit. The rectification control unit inputs a single-phase 220V AC power supply from the phase line input terminal L and the neutral line input terminal N, and outputs a controllable rectification voltage from the first controllable rectification output terminal AC1 and the second controllable rectification output terminal AC2. The speed adjustment unit inputs a controllable rectification voltage from the first controllable rectification input terminal AC1 and the second controllable rectification input terminal AC2 and controls the speed of the stepping motor.

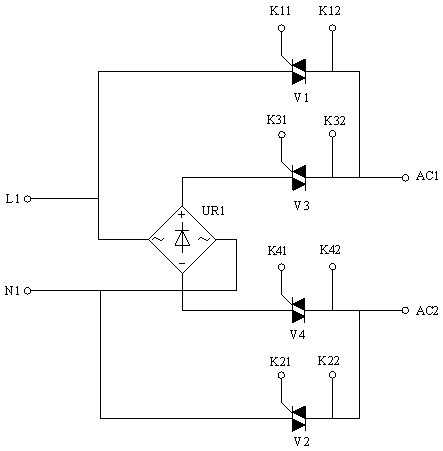

[0074] The structure of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com