Rapid repairing method for superdense-pitch quad fiat no-lead (QFN) device on printed board assembly

A printed board and spacing technology, which is applied in the fields of printed circuit manufacturing, electrical components, printed circuits, etc., can solve problems such as difficult repair, difficult alignment, uncontrollable demoulding, etc., and achieve fast repair, high success rate, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

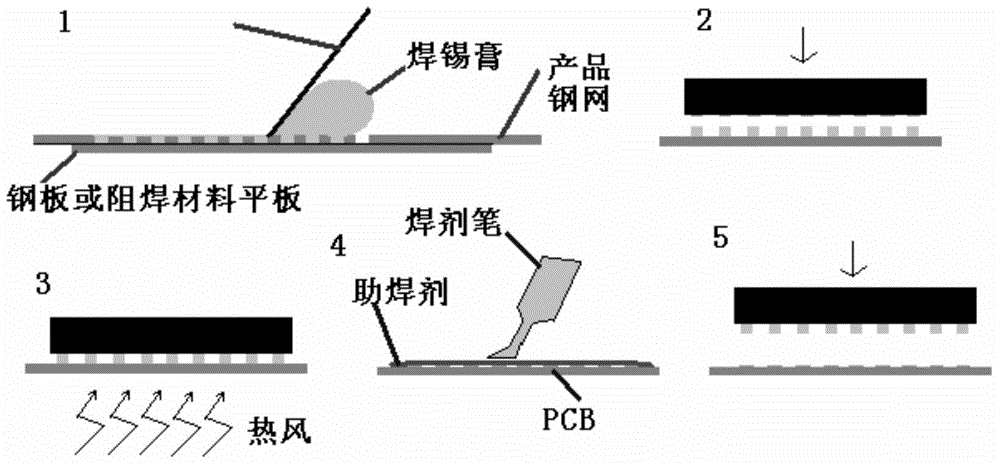

[0026] Below in conjunction with example 1, the process method of the ultra-fine pitch QFN device on the fast repair printed board assembly of the present invention is introduced: use the ERSAIR550A / PL550A rework workstation to repair the ultra-fine pitch QFN device on the DMLF package form on the printed board assembly.

[0027] 1. Solder paste for printing ultra-fine-pitch QFN devices in the form of DMLF packages to be repaired. The specific method is to use the stencil used in the production of the printed board assembly to be reworked to directly transfer the solder paste to a flat steel sheet or thin plate with a solder mask effect.

[0028] 2. Attach the ultra-fine-pitch QFN device in the form of DMLF package to the printed solder paste. Mount MELF components to be reworked on the printed solder paste using equipment with alignment and mounting functions, namely ERSAIR550A / PL550A rework workbench;

[0029] 3. Melt the solder paste under the ultra-fine-pitch QFN device p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com