Axle guide bearings for coupling the rear axle to the vehicle structure of a motor vehicle

A technology of guide bearings and motor vehicles, which is applied in the direction of vehicle springs, vehicle parts, mechanical equipment, etc., can solve the problems of unsuitable torsion beam shaft support, etc., and achieve the effects of improving driving dynamic characteristics, reducing transmission, avoiding noise and wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

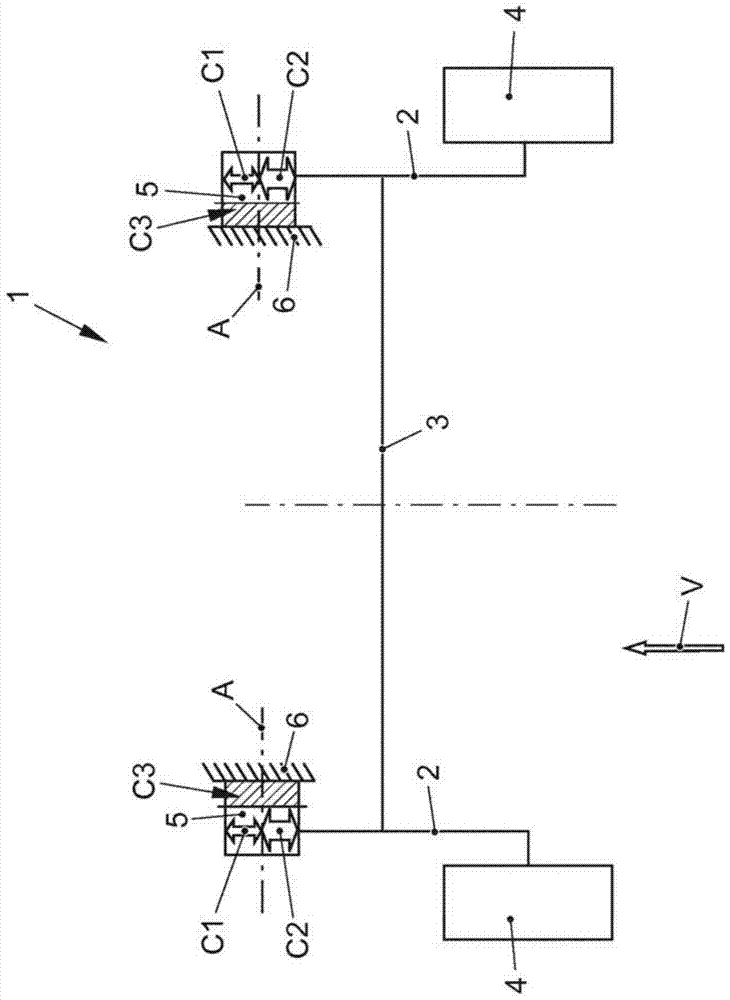

[0025] figure 1 The shown torsion beam rear axle 1 comprises two trailing arms 2 extending mainly in the longitudinal direction of the vehicle, which are connected by means of a cross member 3 . The transverse beam 3 is designed in a known manner to be bending-resistant, but twistable. A wheel carrier for supporting the rear wheels 4 of the vehicle is situated on the rear end section of each trailing arm 2 . Furthermore, each trailing arm 2 is coupled at the front end to the vehicle structure 6 by means of an axle guide bearing 5 .

[0026] In the exemplary embodiment shown, the pivot axis A of the axle guide bearing 5 extends horizontally and transversely to the longitudinal or forward direction V of the vehicle. Starting from this orientation, however, a deviation of the order of magnitude of a maximum of 25° is possible both with respect to the horizontal direction and with respect to the adjustment angle to the longitudinal direction of the vehicle.

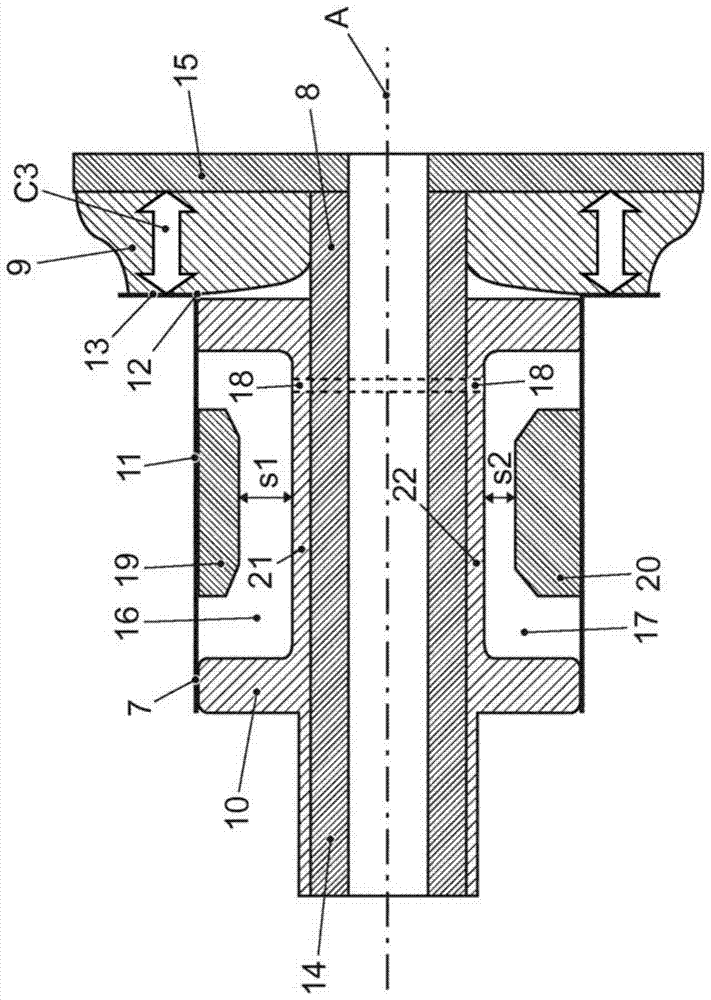

[0027] Axle guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com