Label feeding device

A technology for supplying devices and labels, applied in the directions of labels, packaging, labeling machines, etc., can solve the problems of easy accumulation of adhesives, inability to enter the peeling claw, complex structure, etc., and achieve the effect of reliable peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

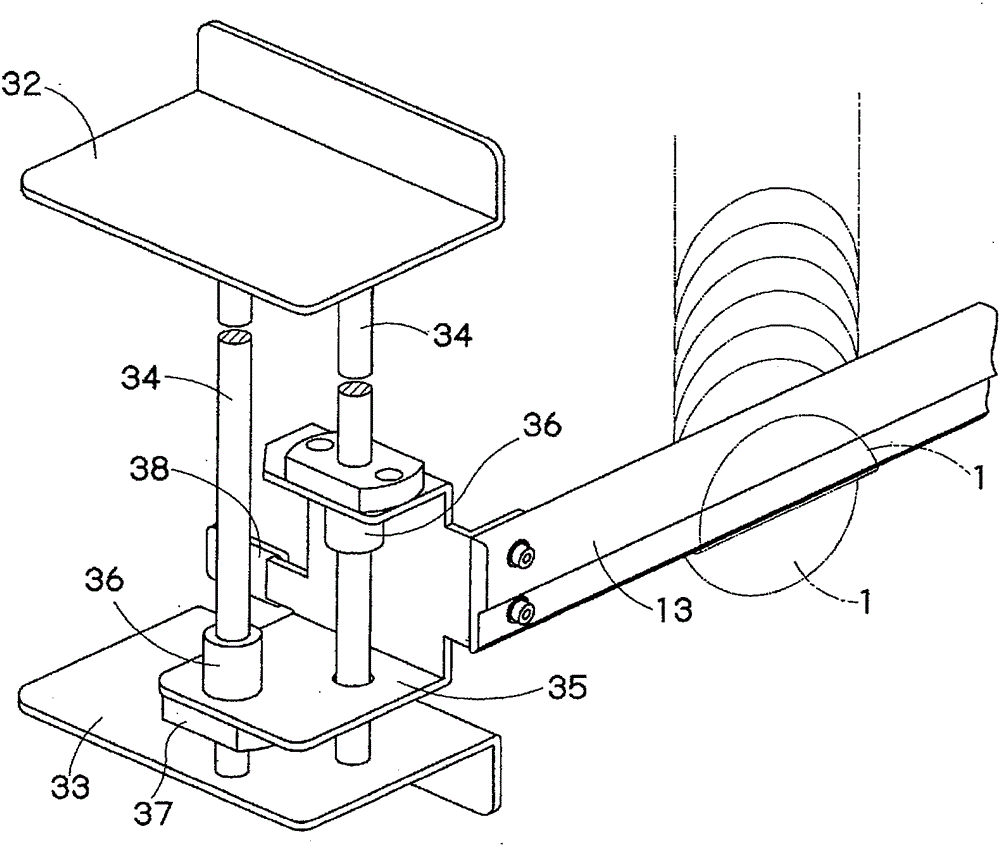

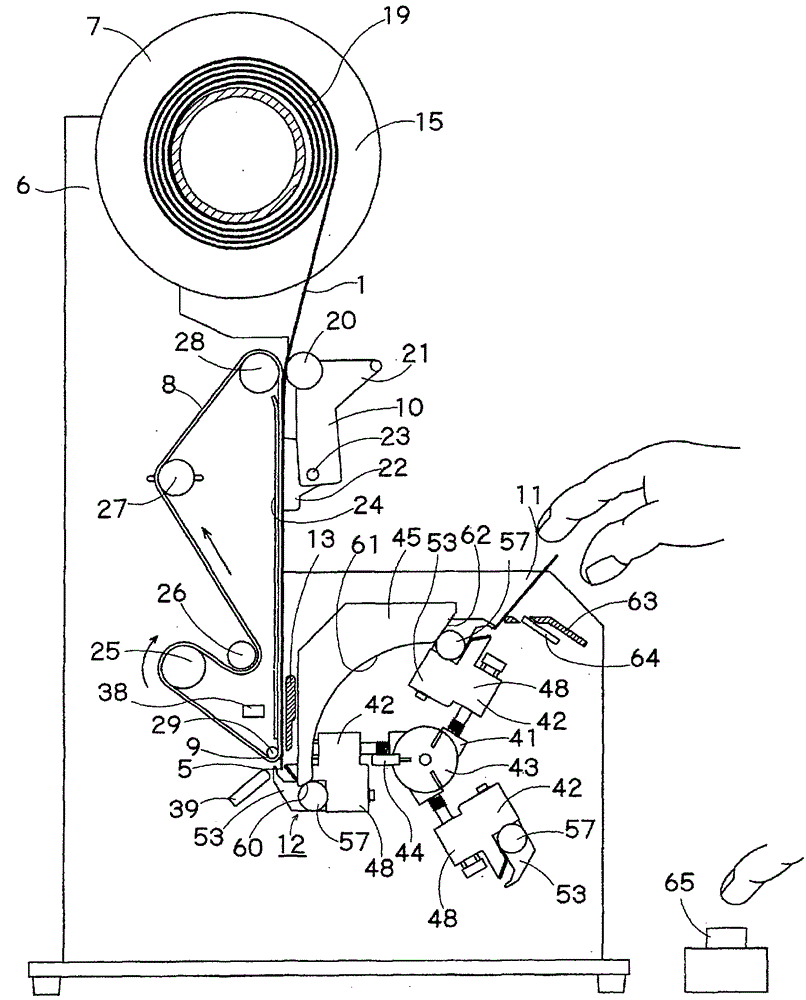

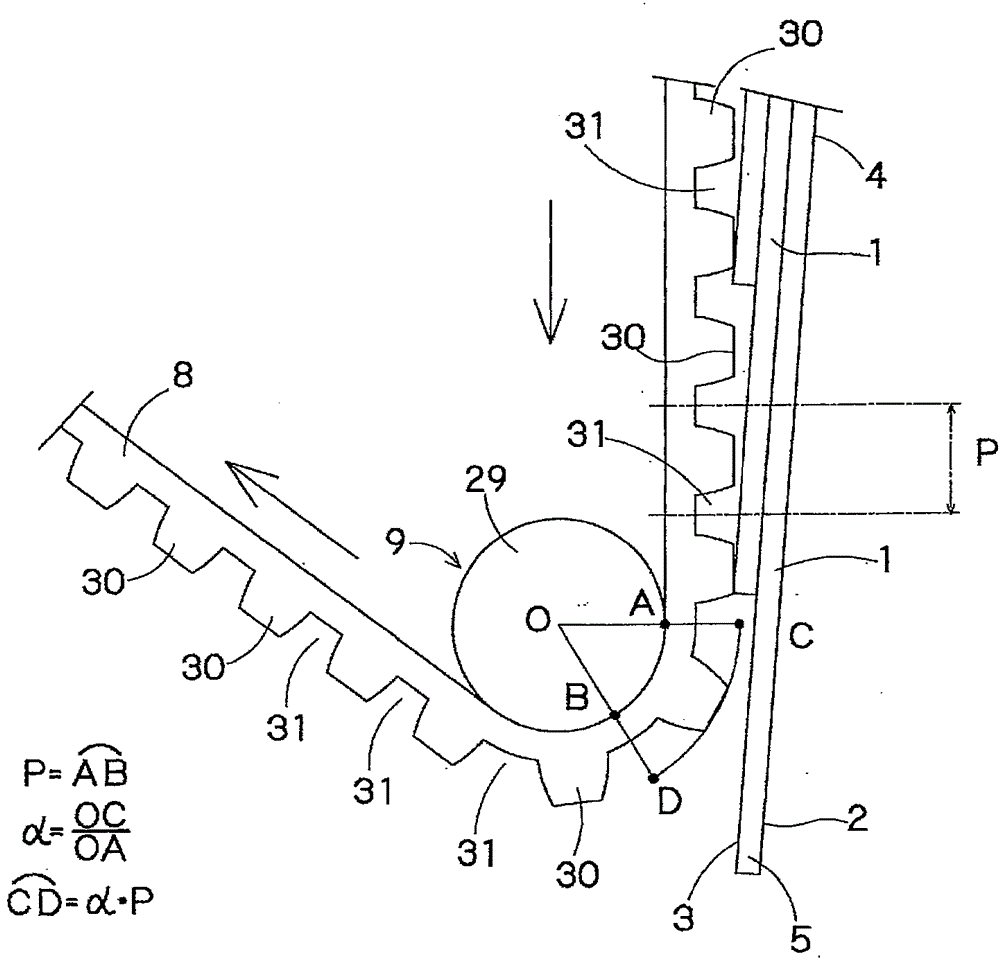

[0024] figure 1 and figure 2 represents an embodiment of the present invention, figure 1 is a stereogram, figure 2 is an explanatory diagram of the structure, and the label 1 to which the present invention is an object is as in image 3 As shown in a partially enlarged manner, a peeling surface is formed on the front surface 2 of the label, and an adhesive surface is provided on the back surface 3, which is offset by a predetermined width and is attached to the surface of the lower label so as to partially overlap. The upper label is almost always overlapped and pasted on the lower label, and the staggered part protrudes forward than the lower label. That is, the overlapping part 4 of the upper label 1 is attached to the lower label, but the offset part 5 is not attached to the lower label directly below, but is attached to the surface of the label after being rolled.

[0025] The label feeding device of the present invention mainly includes: a device main body 6; a ho...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap