Slide bearing for telescopic booms, in particular for shotcrete manipulators or robots

A sliding support, telescopic technology, applied in the direction of anti-centrifugal rotating parts, linear motion bearings, bearings, etc., can solve problems such as sliding support failure, to prevent air gaps, easy to readjust or replace, avoid partial The effect of overload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

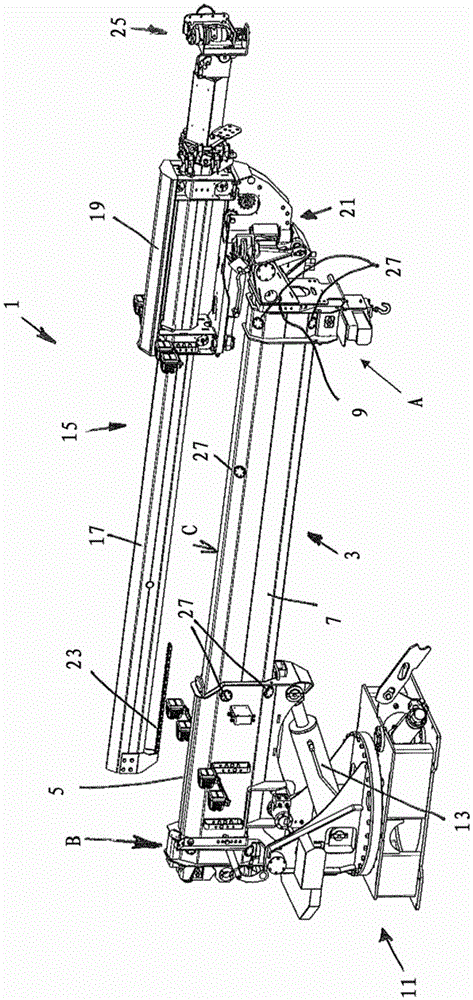

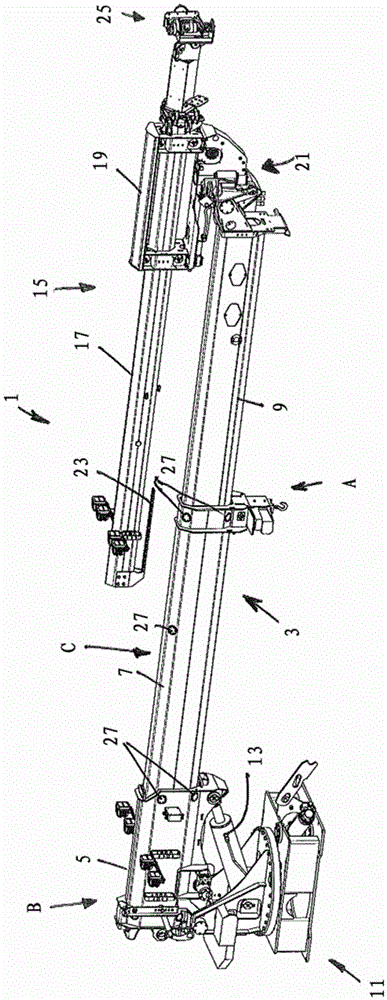

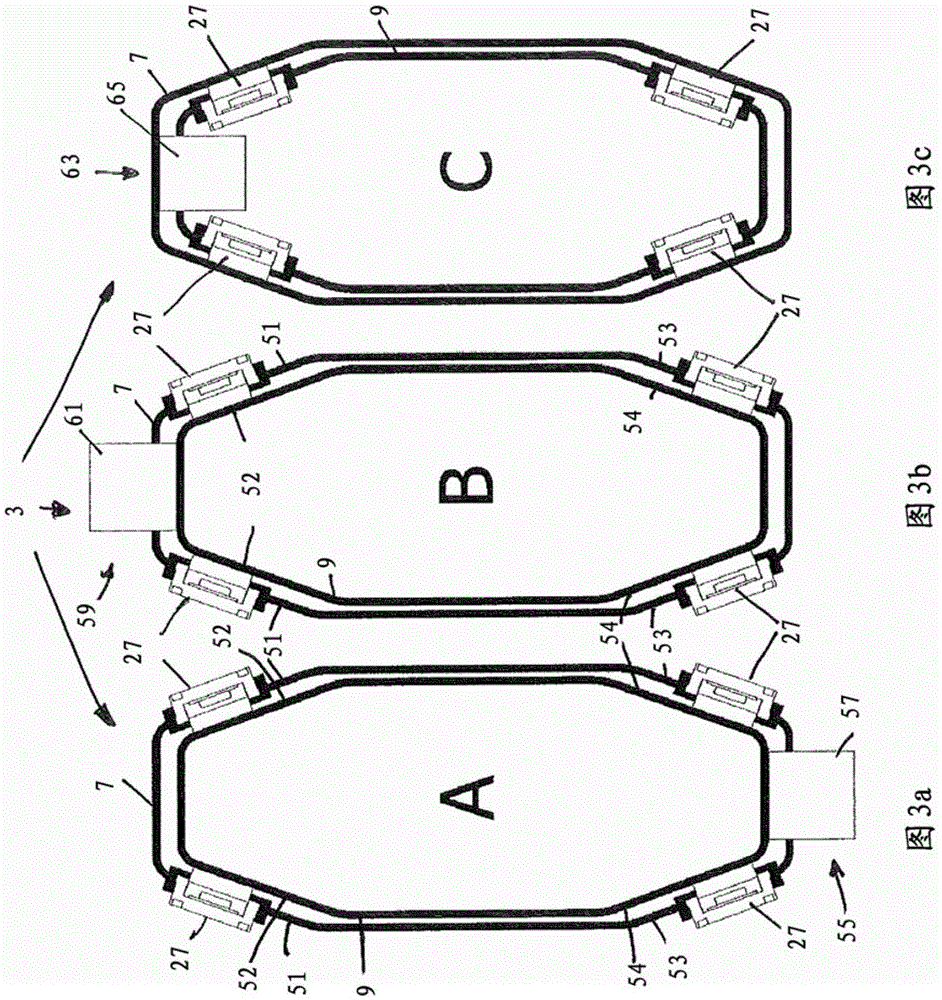

[0040]Reference is now made to the accompanying drawings, which show two different embodiments of the invention, however, both embodiments comprise the same sliding bearing of the invention. Similar components shown in the figures are indicated by the same reference numerals. The wording "arm" should be understood in all combinations as "boom or arm".

[0041] First refer to figure 1 and figure 2 , shows a shotcrete manipulator or robot 1 comprising a telescoping arm 3 with three arm sections 5, 7 and 9 relative to are movable with each other. The position of the arms 7 and 9 shows the first deployed position of the telescopic arm 3 , wherein there is an extended arm section 7 and a retracted arm section 9 . The arm section 7 is also movable within the arm section 5 in the retracted position.

[0042] The arm section 5 is supported by a bearing and fixing unit 11 which is of conventional type and a detailed description is therefore omitted. The bearing and fixing unit 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com