Camshaft connecting-rod type cocoon cluster frame for quickly removing cocoons

A technology of crankshaft connecting rods and silkworm clusters, which is applied in the field of utensils for silk spinning and cocooning on cooked silkworms. It can solve the problems of high labor intensity, low efficiency, and failure to meet production requirements, so as to reduce environmental humidity and prevent hair loss. Yellow, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

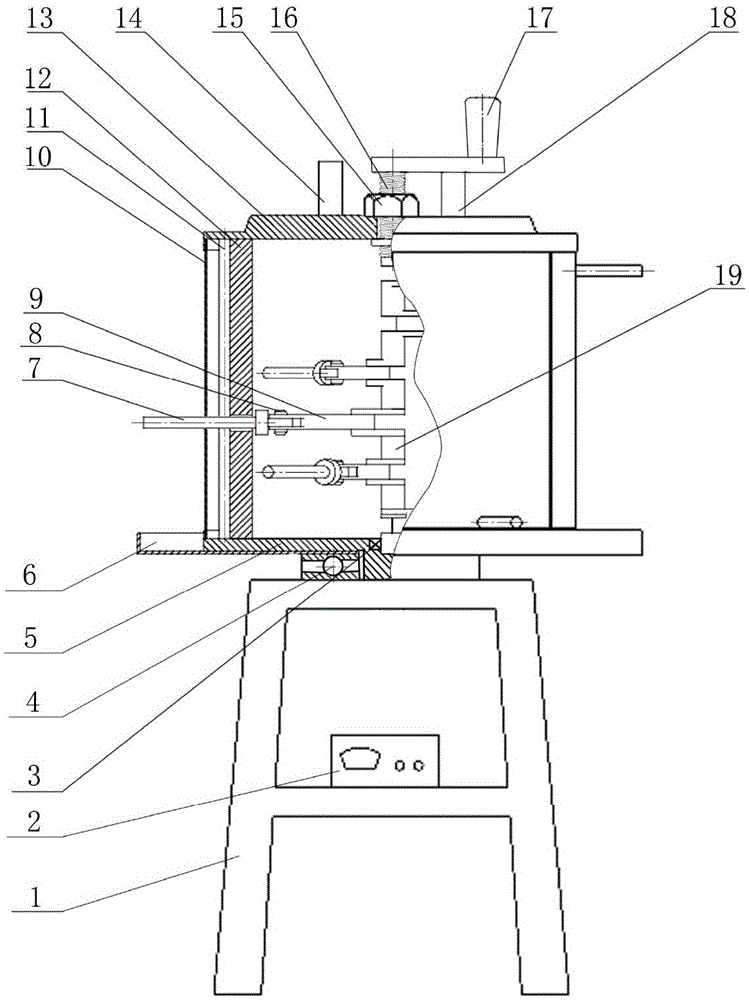

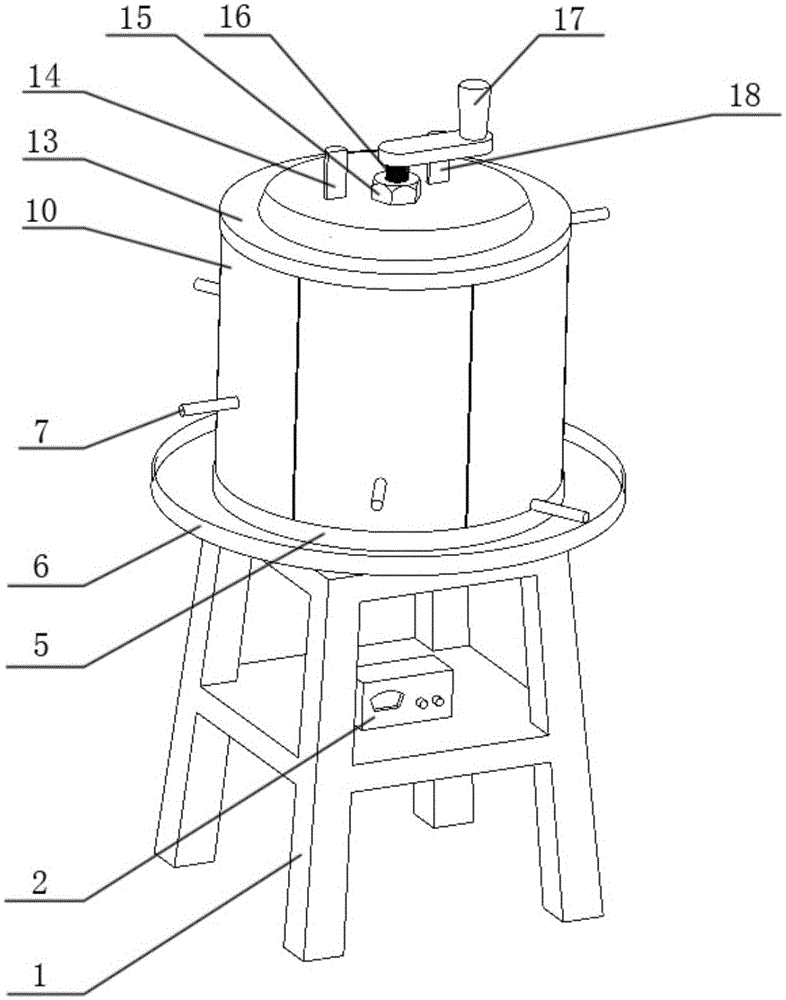

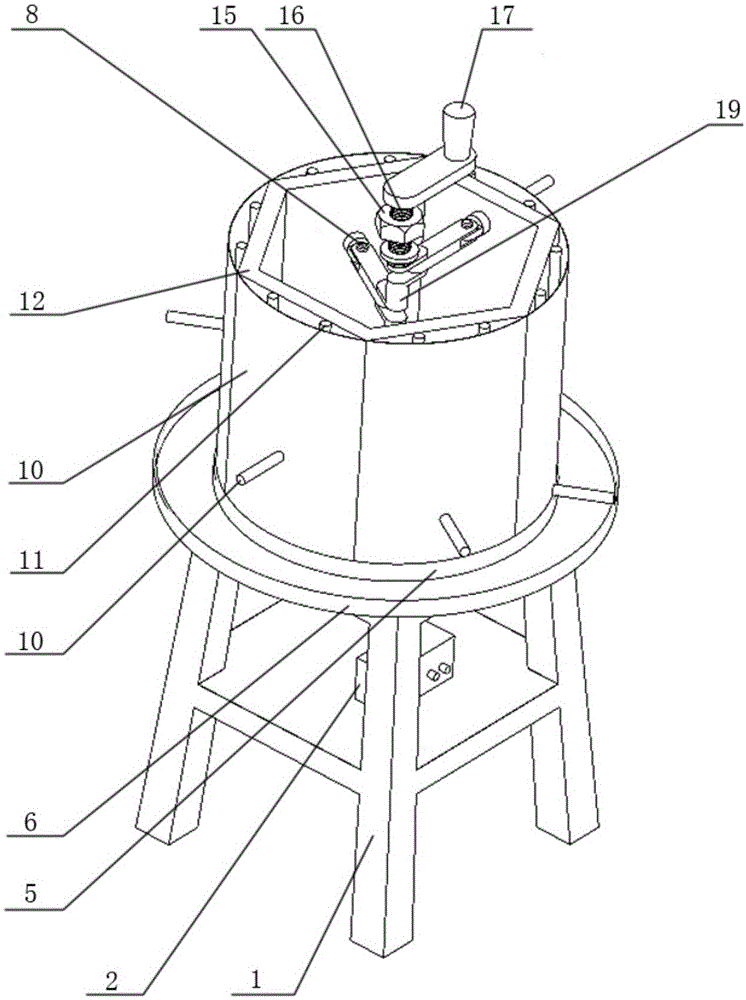

[0021] Such as Figure 1 to Figure 7 As shown, the crankshaft connecting rod type fast silkworm cocoon cluster frame according to the present invention includes a crankshaft connecting rod mechanism, an electronic temperature controller 2, silkworm foil 6, silkworm clusters 7, an isolation protection net 10, a heating wire 11 and a box body 12 . The specific structure and connection relationship are as follows: the crankshaft linkage mechanism is composed of silkworm tuft 7, hinge 8, connecting rod 9 and crankshaft 19, the upper end of the crankshaft 19 is fixedly connected by a threaded rod 16 handle 17 with a limit protrusion, and the lower end Interference fit with the inner ring of deep groove ball bearing 3 embedded in the lower case cover 5, the crank throw on the crankshaft 19 and the through hole on the connecting rod 9 cooperate to form a rotating pair, and the connecting rod 9 is connected to the silkworm cluster 7 through a hinge 8 , the circular through hole corre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com