Soft capsule robot sorting system and method

A sorting system and soft capsule technology, applied in the field of medical machinery automation, can solve the problems of poor sorting effect and efficiency, missed detection, etc., and achieve high accuracy and automation, high sorting efficiency, and short sorting time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

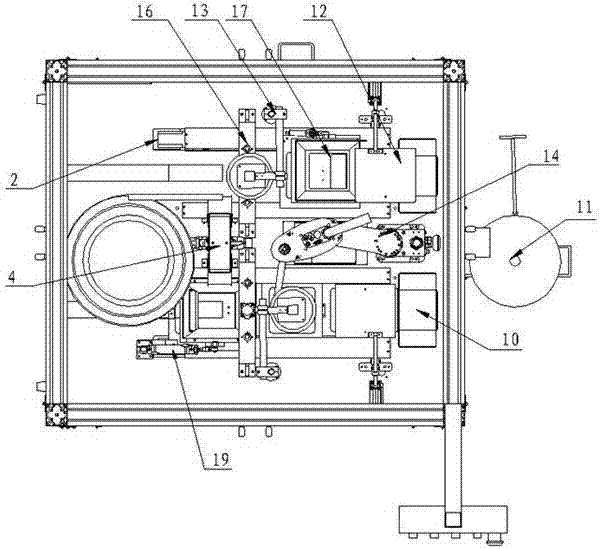

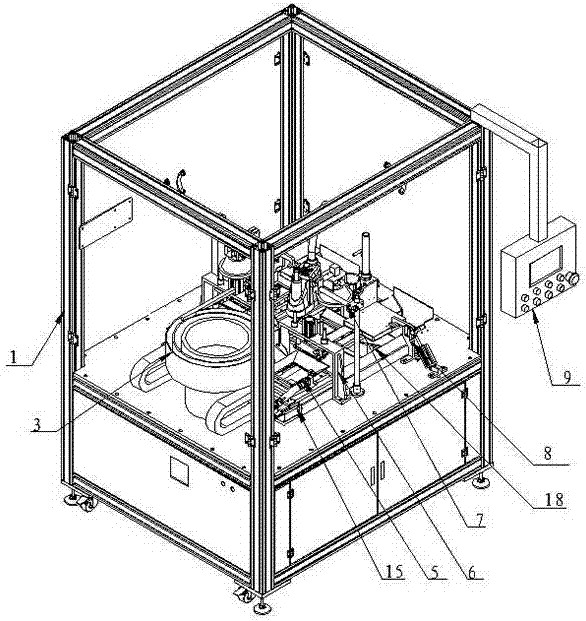

[0042] Such as figure 1 , figure 2 As shown, the soft capsule robot sorting system includes a workbench 1, and the workbench 1 is provided with a vibrating feeding mechanism 3, a weighing and distributing mechanism 4, a first moving feeding mechanism, a first visual recognition mechanism, a second Mobile feeding mechanism, the second visual recognition mechanism and sorting robot 14; The weighing and distributing mechanism 4 is located at the outlet end of the vibrating feeding mechanism 3; The first moving feeding mechanism and the second moving feeding mechanism are arranged in parallel on the scale On both sides of the redistribution mechanism 4, the first visual recognition mechanism is set on the same side as the first mobile feeding mechanism, and the first visual recognition mechanism is located at the upper end of the first mobile feeding mechanism, and the second visual recognition mechanism is connected to the upper end of the first mobile feeding mechanism. The se...

Embodiment 2

[0052] This embodiment has been further optimized on the basis of Embodiment 1, specifically: the first moving feeding mechanism includes a first feeding tray 5 and a first servo traveling mechanism 15, and the first feeding tray 5 can be moved in the first Driven by the servo traveling mechanism 15, the linear motion is done; the second mobile feeding mechanism includes a second feeding tray 17 and a second servo traveling mechanism 2, and the second feeding tray 17 can be driven in a straight line by the second servo traveling mechanism 2. sports.

[0053] The first feeding tray 5 and the second feeding tray 17 of this embodiment are used to hold the soft capsules, and the soft capsules are delivered under the action of the first servo traveling mechanism 15 and the second servo traveling mechanism 2, with stable transportation and simple structure.

[0054] Preferably, cylinders 19 are connected to the sides of the first feeding tray 5 and the second feeding tray 17 . The ...

Embodiment 3

[0056] This embodiment is further optimized on the basis of Embodiment 1 or Embodiment 2, specifically: the first visual recognition mechanism includes No. 1 camera 7 and No. 2 camera 8 arranged in a straight line; The mechanism includes a No. 3 camera 12 and a No. 4 camera 13 arranged in a straight line.

[0057] The No. 1 camera 7 and the No. 2 camera 8 of this embodiment can identify the soft capsules delivered by the first mobile feeding mechanism. The No. 1 camera 7 initially identifies and screens the soft capsules, and the soft capsules with larger appearance defects and larger appearance stains are identified. Capsules with large differences in color and weight are selected, and the second camera 8 performs precise screening to select capsules with smaller differences until the sorting of all unqualified capsules is completed. Similarly, the third camera 12 and the fourth camera Camera 13 then carries out preliminary and accurate screening to the soft capsule of second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com