Ladle capping device

A ladle and molten iron technology, applied in metal processing equipment, casting molten material containers, casting equipment, etc., can solve problems such as uneven temperature of molten iron, poor working environment for workers, influence of molten iron transportation scheduling, etc., to achieve obvious effects, Save consumption and design simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments, the purpose is only to understand the technical solution of the present invention more clearly, and the examples cited are not intended to limit the scope of protection of the present invention.

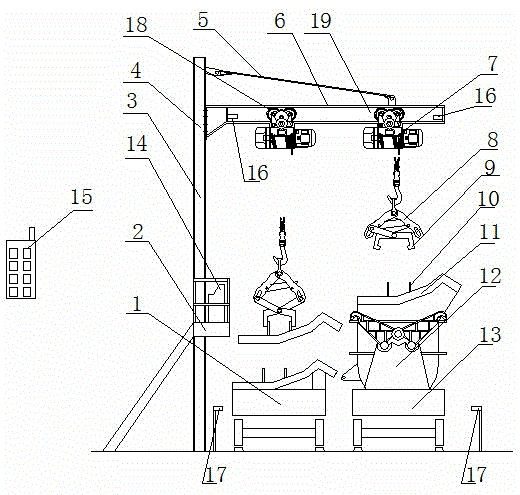

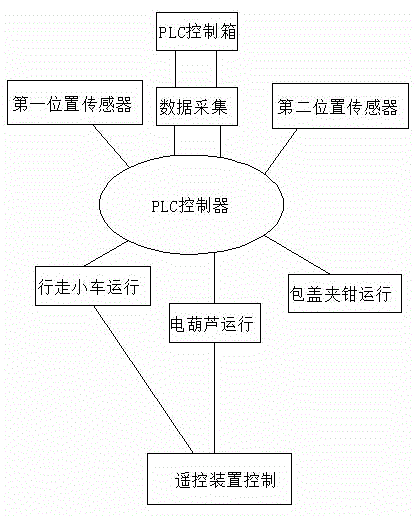

[0024] A ladle capping device, comprising a frame, a lifting device, a ladle cover 11, a trolley 1, a ladle car 13, a ladle cap clamping device and a control system; The ladle cover 11 is connected, and the other end is connected with the frame, and the lifting device can move laterally relative to the frame; and cover removal operation; the traveling trolley 1 and the hot metal charter car 13 run in opposite directions, and run back and forth relative to the frame; the control system includes a PLC control box 14, an operating platform 2 and a remote control device 15.

[0025] In the present embodiment, the hot metal ladle cover clamping device comprises a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com