Rotating extrusion apparatus for machining temperature-sensitive cylinder

A technology of extrusion equipment and temperature-sensing cylinder, which is applied in the field of rotary extrusion equipment, can solve the problems of low processing efficiency and easy deformation of the temperature-sensing cylinder, and achieve the effects of convenient modification, avoiding deformation, and precise size control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

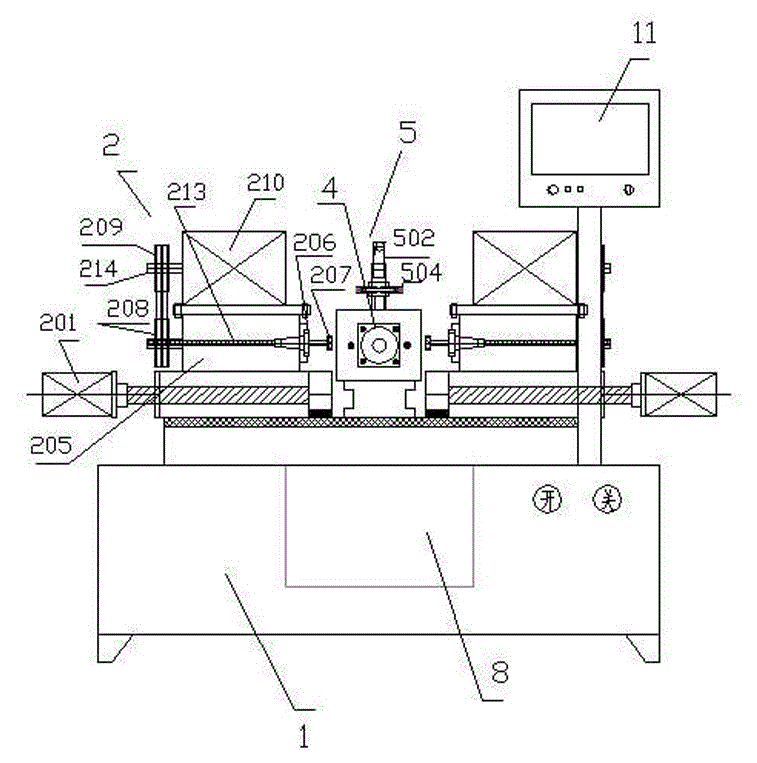

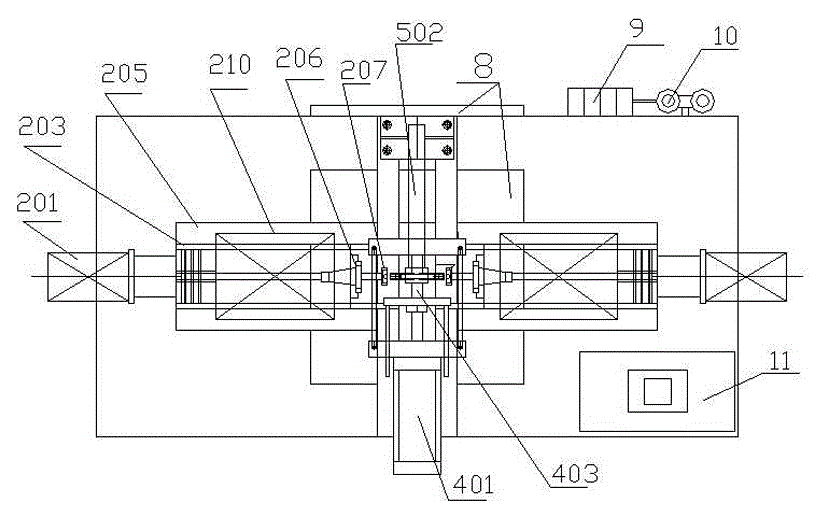

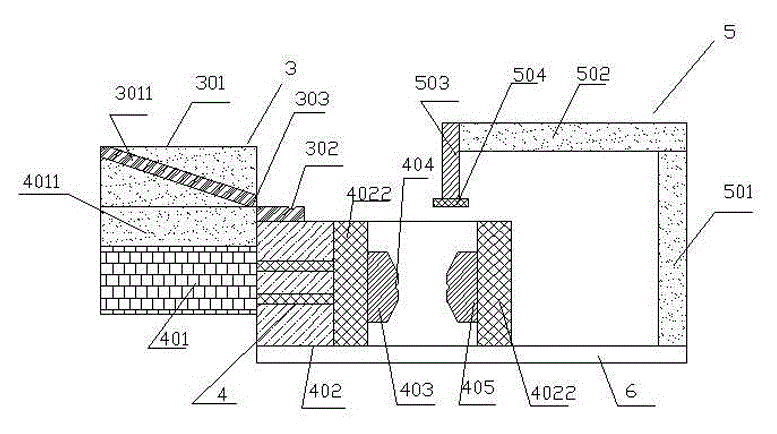

[0029] Attached below Figure 1-5 To illustrate the present invention.

[0030] figure 1 , figure 2 The shown rotary extrusion equipment for processing a temperature-sensitive cylinder includes a processing table 1, and the processing table 1 is provided with two rotary extrusion mechanisms 2, and the two rotary extrusion mechanisms are left-right symmetrical, so A discharge structure 3, a clamping mechanism 4 and a clamping mechanism 5 are arranged between the two rotary extrusion mechanisms 2;

[0031] The rotary extrusion mechanism 2 includes a servo motor 201, a screw guide rail 202, a screw seat 203, a first screw mandrel 204, an XL cutting head 205, a cutter bar 206, a shrinking tube cutter head 207, a first transmission pulley 208, a first Two transmission pulleys 209, a three-phase motor 210, the first screw mandrel 204 is located on the screw guide rail 202, one end of the first screw mandrel 204 is fixedly connected to the fixed seat 211, and the fixed seat 211 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com