Concrete mixer

A technology for concrete mixers and mixing drums, applied in cement mixing devices, clay preparation devices, chemical instruments and methods, etc., can solve problems such as easy sedimentation, long time, not practical enough, etc., achieve efficient mixing, convenient movement, and improve quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The invention provides a concrete mixer, which is mainly used for mixing concrete. The invention can not only mix the concrete efficiently, but also grind the impurities with larger particles in the concrete, which greatly improves the quality of the concrete, thereby The quality of the building is improved, and the concrete mixer is easy to move, and the concrete in the mixer can be completely discharged without blocking the mixer and causing no waste.

[0015] In order to better understand the above-mentioned technical solution, the above-mentioned technical solution will be described in detail below in conjunction with the accompanying drawings and specific implementation methods.

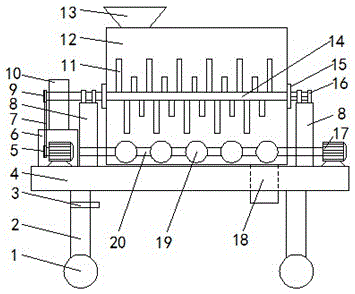

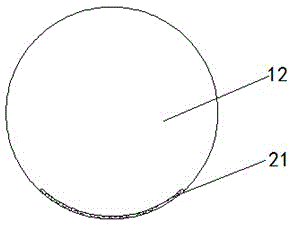

[0016] see Figure 1-2 As shown, a concrete mixer includes a bracket 4, a mixing drum 12 and a motor 17, and is characterized in that it also includes a wheel 1, a leg 2, a lifting device 3, a first pulley 5, a cavity 6, a belt 7, and a pillar 8. The second pulley 9, the fixed table 10, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com