Dust-free environment-friendly board eraser

An environmentally friendly technology for board erasing, applied in the field of blackboard erasing, can solve the problems of difficult removal, dust isolation in the dust holding room, limited application scope, etc., to save the use cost, avoid secondary pollution, and have a wide range of applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

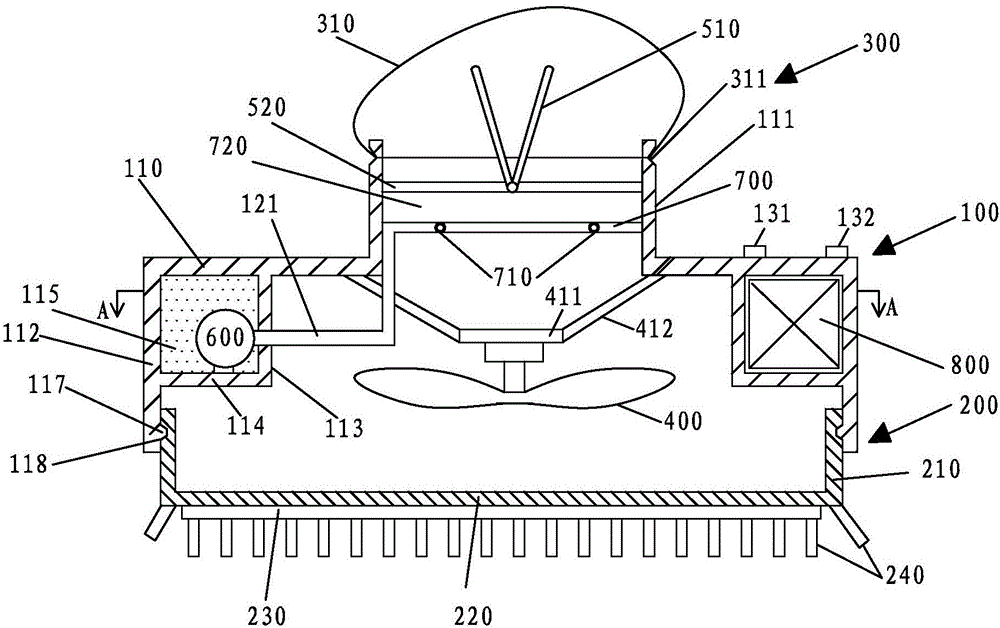

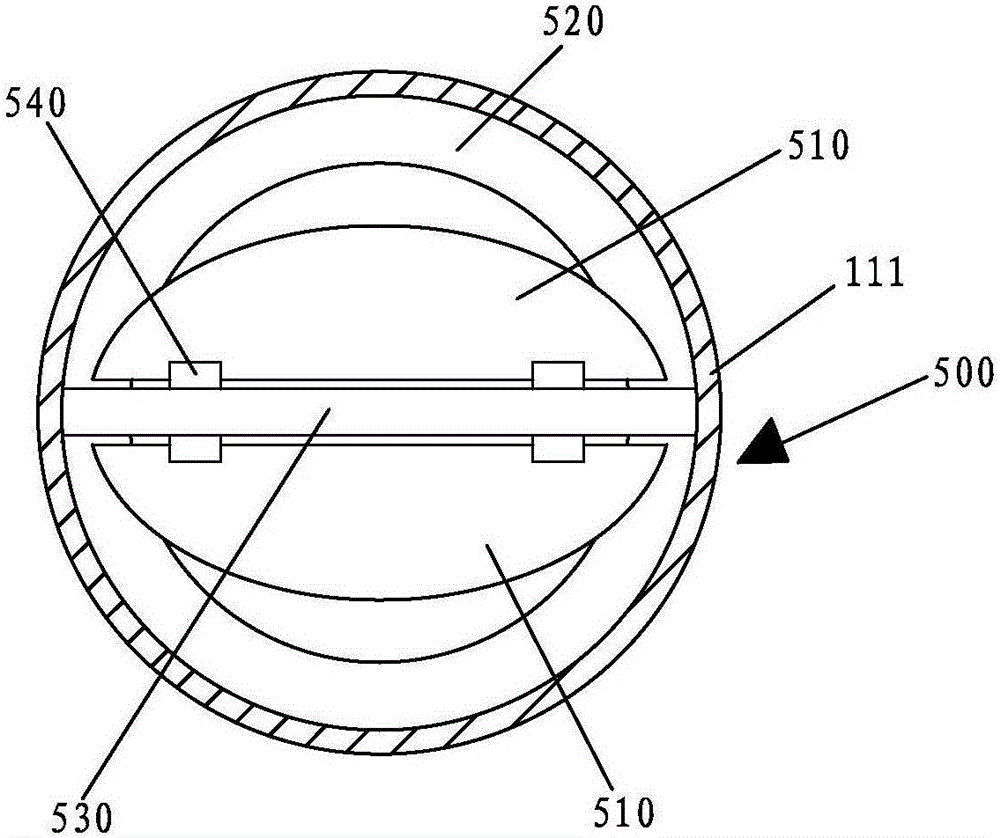

[0048] The invention provides a dust-free environmental protection eraser, such as figure 1 As shown, the dust-free environmental protection eraser includes a cleaning module 200, an atomizing dust removal module 100 detachably combined with the upper end of the cleaning module 200, and a dust collection unit detachably combined with the upper end of the atomizing dust removal module 100. Module 300.

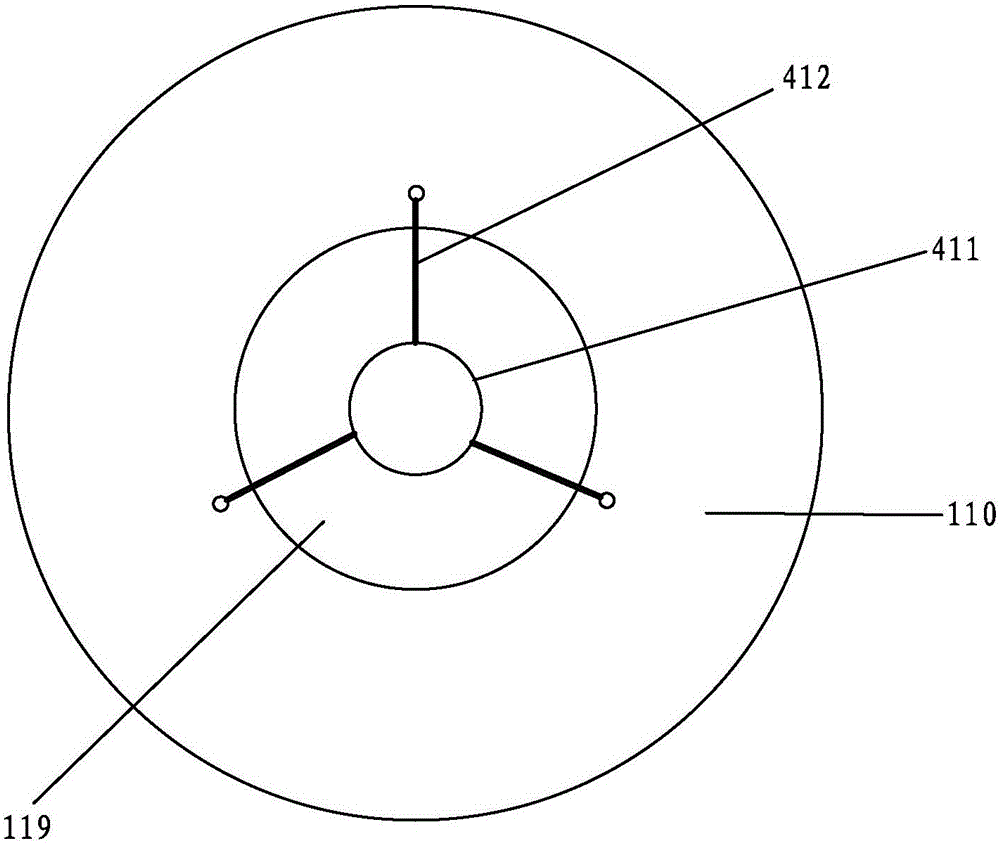

[0049] Such as figure 1 and figure 2 As shown, the atomizing dust removal module 100 includes a base plate 110 with a through hole 119 at the center, a first annular body 111 extending upwards around the through hole 119 on the upper surface of the base plate 110, and a lower surface at the periphery of the base plate 110. The second annular body 112 extending downward, the third annular body 113 extending downward on the inner side of the second annular body 112 on the lower surface of the substrate 110, and the outer wall connected to the third annular body 113 and the she...

Embodiment 2

[0062] As an alternative embodiment, other aspects are the same as embodiment 1, the difference is: as Image 6 As shown, the eraser body 220 is formed as a grid-like member, and the eraser body 220 includes 3 vertical bars and 3 horizontal bars that cross the 3 vertical bars respectively, and each vertical bar and each horizontal bar Both ends of the portion are respectively connected to the inner wall of the lower fixed end of the fourth annular body 210, and the wiping elements 230 attached to the lower surface of the eraser body 220 are bristles.

Embodiment 3

[0064] As an alternative embodiment, other aspects are the same as Embodiment 1, except that the first detachable fitting part 117 is an external thread part arranged on the outer side wall of the lower end of the second annular body 112, and the second The detachable matching portion 118 corresponds to an internal thread portion disposed on the inner sidewall of the upper end portion of the fourth annular body 210 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com