Kinetic-static energy conversion type fresh air system

A fresh air system and conversion technology, applied in railway car body parts, railway vehicle heating/cooling, transportation and packaging, etc., can solve passenger injuries and other problems, achieve the effect of increasing the overall height, ensuring driving safety, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

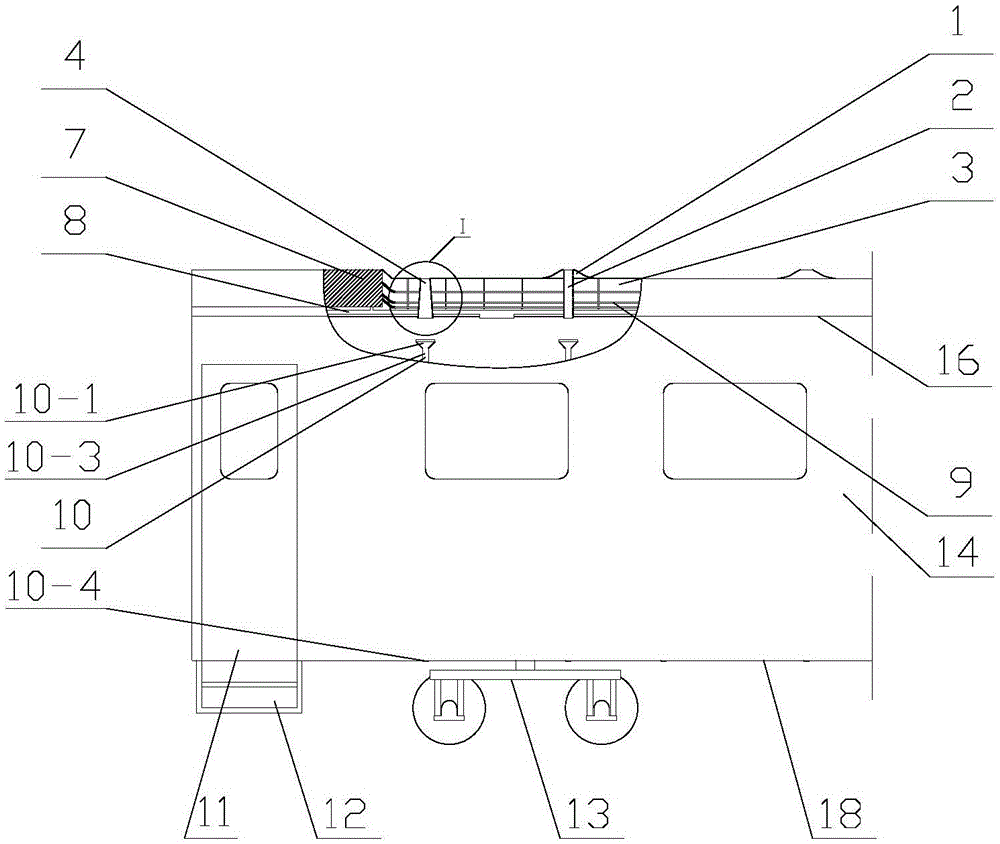

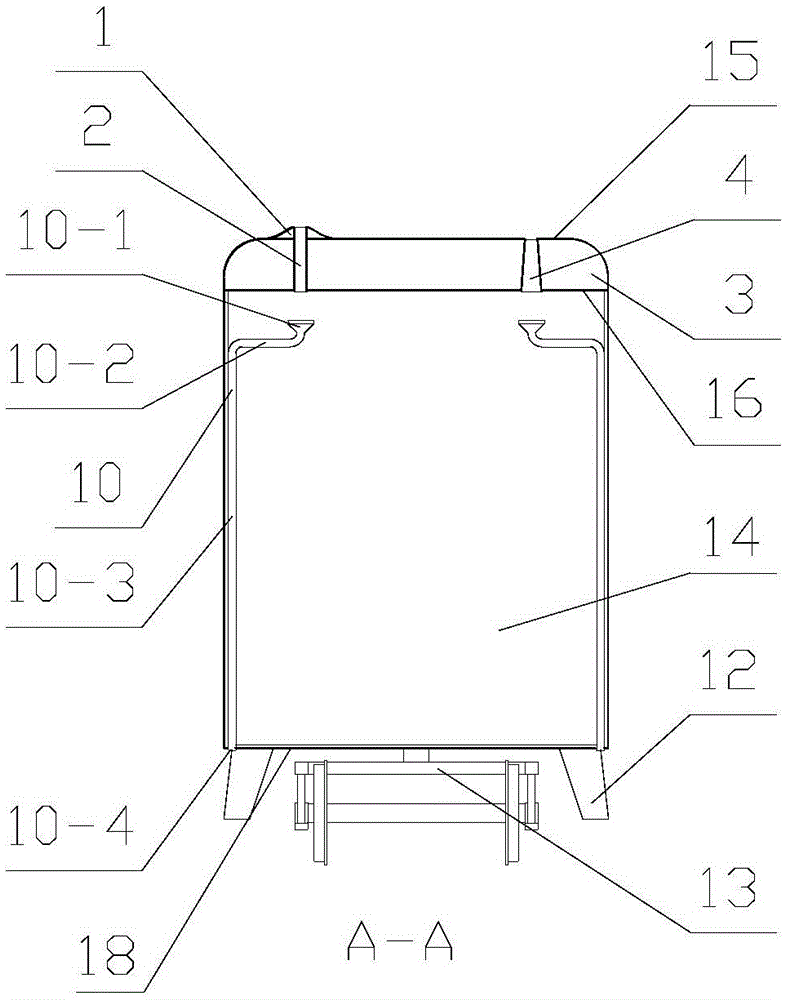

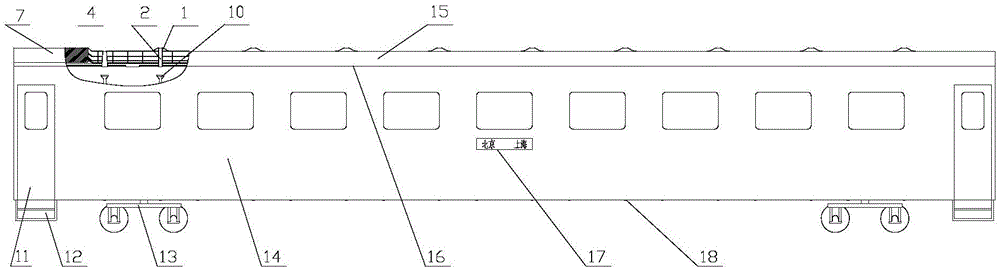

[0061] 1. Dynamic and static energy conversion fresh air system, including: negative pressure air nozzle 1, negative pressure ventilation pipe 2, roof equipment compartment 3, positive pressure ventilation pipe 4, rain drainage assembly 10, compartment 14, roof skin 15, compartment Ceiling 16, compartment floor 18; (Note: the roof skin is the roof shell);

[0062] The positive pressure ventilation pipe 4 includes: the upper nozzle 4-1 of the positive pressure pipe and the lower nozzle 4-2 of the positive pressure pipe; the rain drainage assembly 10 includes: a rainwater funnel 10-1, a rain drainage horizontal pipe 10-2, Pipe 10-3, rain discharge nozzle 10-4;

[0063] It is characterized by:

[0064] Negative pressure ventilation pipe 2 is a cylindrical pipe; Positive pressure ventilation pipe 4 is a tube in the shape of a trumpet with upper nozzle 4-1 on the positive pressure pipe and a lower nozzle 4-2 on the positive pressure pipe; Upper nozzle 4 on the positive pressure pi...

Embodiment 2

[0087] 1. Dynamic and static energy conversion fresh air system, including: negative pressure air nozzle 1, negative pressure ventilation pipe 2, roof equipment compartment 3, positive pressure ventilation pipe 4, rain drainage assembly 10, compartment 14, roof skin 15, compartment Ceiling 16, compartment floor 18; (Note: the roof skin is the roof shell);

[0088] The positive pressure ventilation pipe 4 includes: the upper nozzle 4-1 of the positive pressure pipe and the lower nozzle 4-2 of the positive pressure pipe; the rain drainage assembly 10 includes: a rainwater funnel 10-1, a rain drainage horizontal pipe 10-2, Pipe 10-3, rain discharge nozzle 10-4;

[0089] It is characterized by:

[0090] Negative pressure ventilation pipe 2 is a cylindrical pipe; Positive pressure ventilation pipe 4 is a tube in the shape of a trumpet with upper nozzle 4-1 on the positive pressure pipe and a lower nozzle 4-2 on the positive pressure pipe; Upper nozzle 4 on the positive pressure pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com