C/C-SiC composite material prepared by using silicon-containing aryne resin, and preparation method thereof

A technology of resin composite materials and composite materials, applied in the field of C/C-SiC composite materials and their preparation, can solve the problem of increasing the difficulty and cost of C/C-SiC composite materials, large porosity of composite materials, and carbonization residual rate No problems such as high, achieve the effect of high thermal decomposition residual rate, high ceramization rate, and outstanding thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

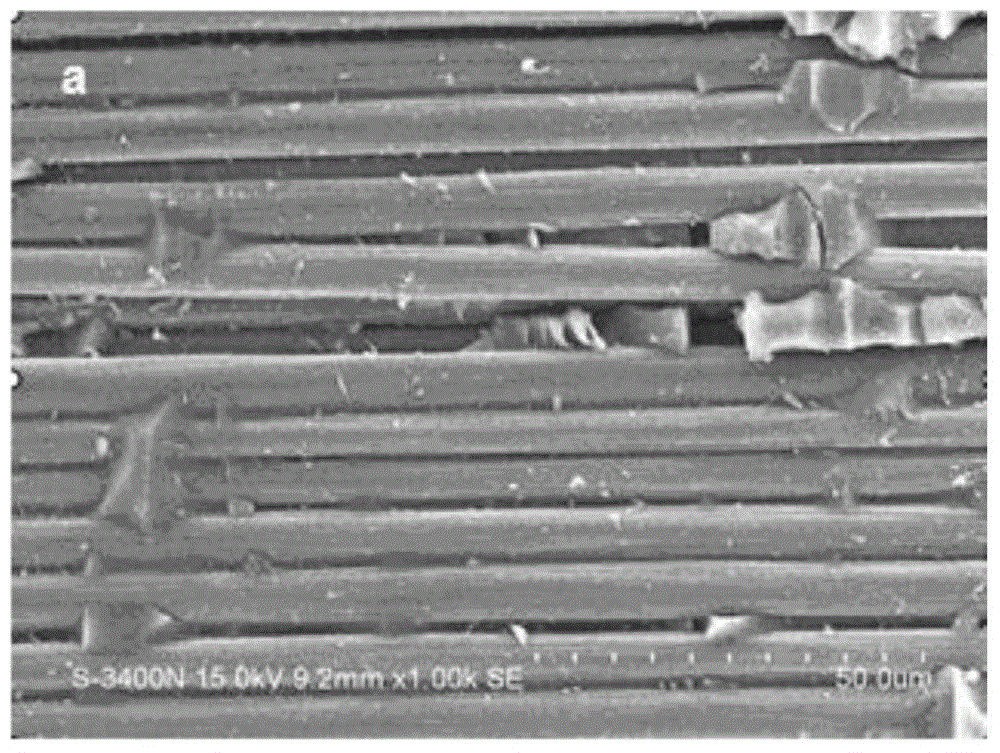

[0043] Fabrication of T300 Carbon Cloth Reinforced C / C-SiC Composites by Impregnation at Atmospheric Pressure

[0044] 1) Preparation of T300 carbon cloth reinforced silicon-containing aryne resin composites

[0045] Take 12 layers of 15×25cm T300 carbon cloth, lay them flat and stack them; take 50g of silicon-containing aryne resin and dissolve it in 93g of tetrahydrofuran to prepare a tetrahydrofuran solution of silicon-containing aryne resin. Immerse the fiber laminate in the solution, take it out and wait for the solvent in the solution to volatilize, put the prepreg in a vacuum oven at 60°C, vacuumize for 2 hours, remove the solvent, place the carbon containing the resin on a flat vulcanizer and pressurize it (6MPa) Curing, the curing process conditions are: 170°C / 2h+210°C / 2h+250°C / 4h to obtain a T300 carbon cloth reinforced silicon-containing aryne resin composite material.

[0046] 2) Carbon cloth reinforced silicon-containing aryne resin composite material car...

Embodiment 2

[0051] Fabrication of Carbon Cloth Reinforced C / C-SiC Composites by Vacuum Impregnating T300

[0052] 1) Preparation of T300 carbon cloth reinforced silicon-containing aryne resin composites

[0053] With the first step in embodiment 1.

[0054] 2) Carbon cloth reinforced silicon-containing aryne resin composite material carbonization

[0055] Same as the second step in Example 1.

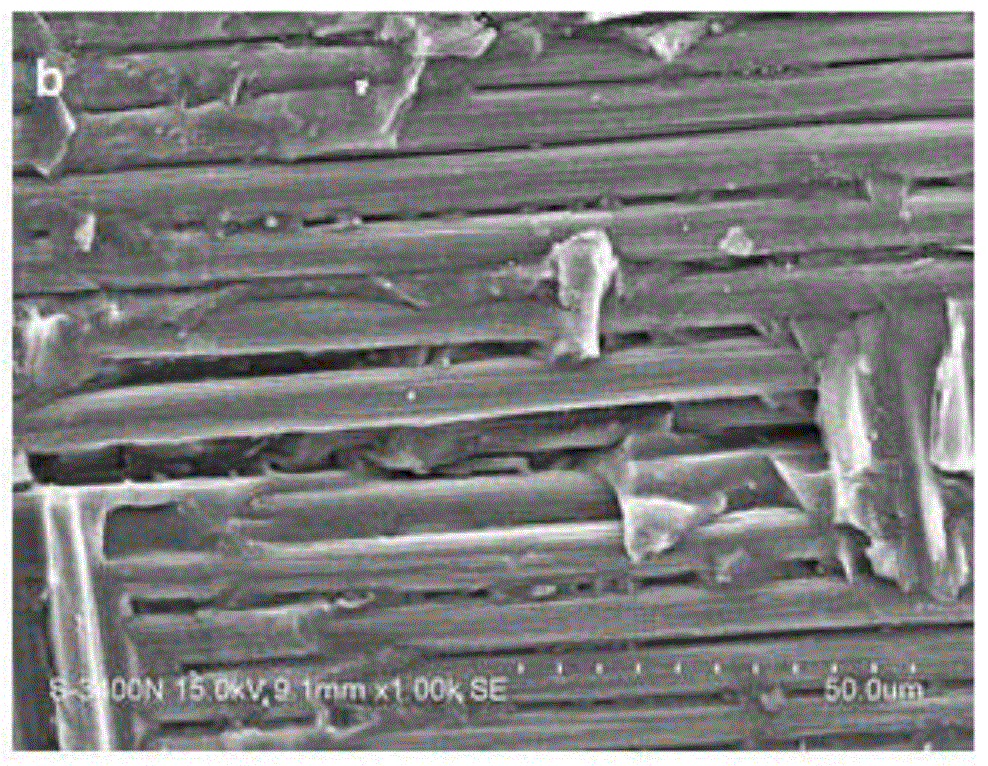

[0056] 3) Densification of 2DC / C-SiC composites

[0057] Prepare 45wt% tetrahydrofuran solution of silicon-containing aryne resin, put the porous C / C-SiC composite material vacuum tank prepared in the previous step, vacuumize for 10min, and then inject the tetrahydrofuran solution of silicon-containing aryne resin into the vacuum tank for 10min, Place in a vacuum oven at 60°C for 2 hours to remove the solvent. Then place it in an oven for curing, and the curing process conditions are: 170°C / 2h+210°C / 2h+250°C / 4h. Finally, it was carbonized at 1450°C for 6h. Repeat the densification...

Embodiment 3

[0059] T300 Carbon Cloth Reinforced C / C-SiC Composites Prepared by High Dipping Times

[0060] 1) Preparation of T300 carbon cloth reinforced silicon-containing aryne resin composites

[0061] With the first step in embodiment 1.

[0062] 2) Carbon cloth reinforced silicon-containing aryne resin composite material carbonization

[0063] Same as the second step in Example 1.

[0064] 3) Densification of 2DC / C-SiC composites

[0065] The densification process is the same as the third step in the embodiment. The C / C-SiC composite material with better performance can be obtained by increasing the number of densification times. When the number of densification times reaches 5, the obtained C / C-SiC composite material has a flexural strength of 209.3 MPa and a flexural modulus of 51.7 GPa. Inter-shear strength 19.2MPa, porosity 6.9%, density 1.58g / cm -3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com