Preparation method and application of bacterial cellulose/polyaniline/carbon nanotube conducting film material

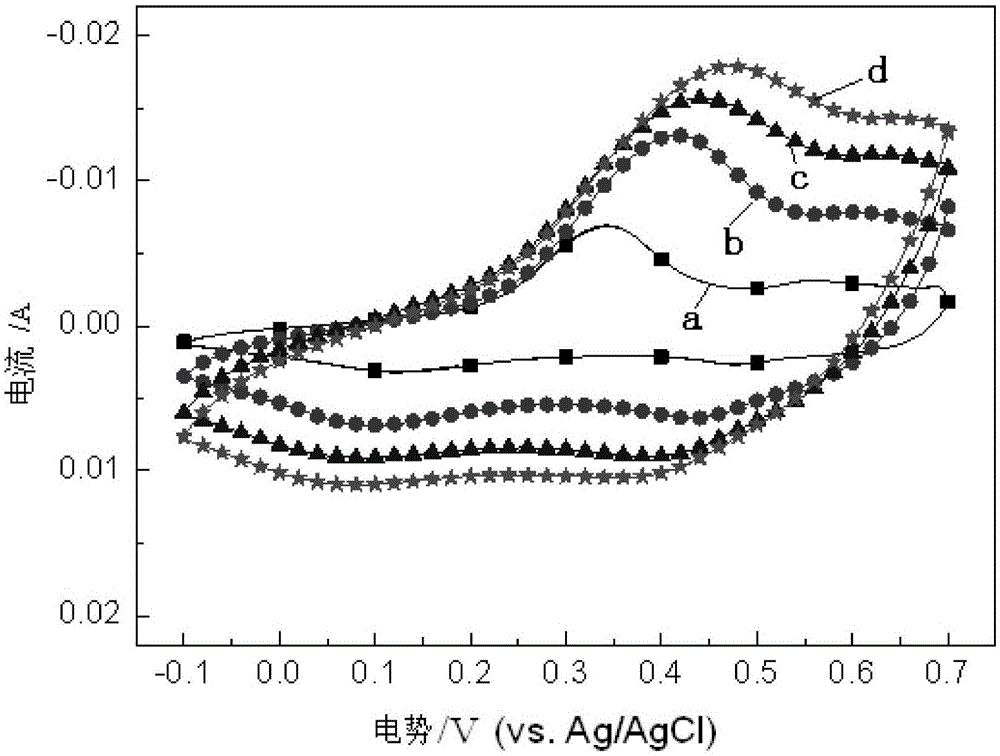

A technology of bacterial cellulose and carbon nanotubes, applied in hybrid capacitor electrodes and other directions, can solve the problems of high cost, lack of stability and mechanical properties, complex preparation process, etc., and achieves low toxicity, good stability and mechanical properties, Simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

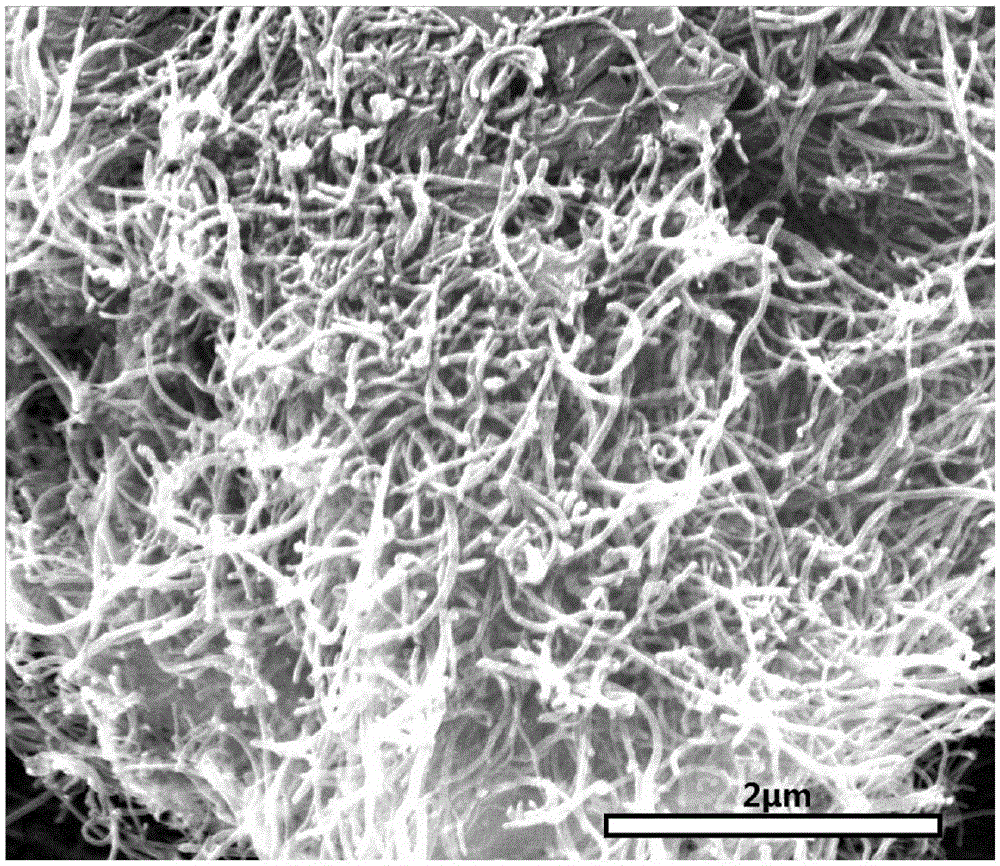

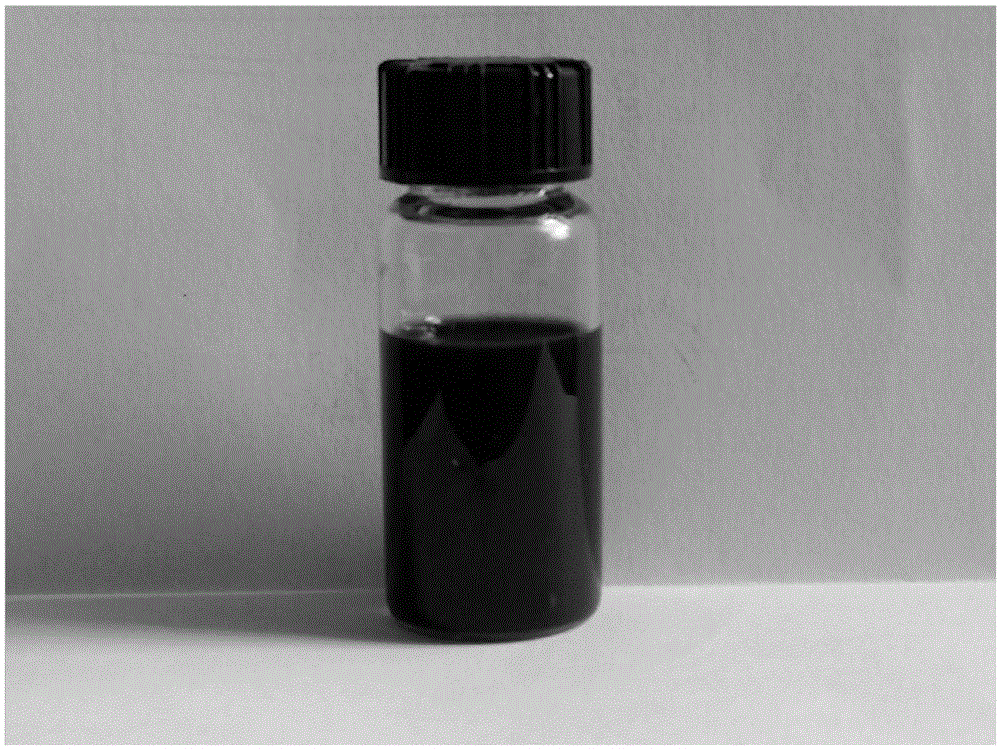

[0023] Specific embodiment one: the preparation method of a kind of bacterial cellulose / polyaniline / carbon nanotube conductive film material of this embodiment is carried out according to the following steps:

[0024] 1. Cut the bacterial cellulose into pieces, soak it in deionized water and ultrasonically wash it, then place it in deionized water, stir to make it evenly dispersed, and then transfer it to a homogenizer for stirring to obtain a bacterial cellulose slurry;

[0025] 2. Mix the aniline monomer with a hydrochloric acid solution with a concentration of 1mol / L to obtain the hydrochloric acid solution of the aniline monomer; add the hydrochloric acid solution of the aniline monomer to the bacterial cellulose slurry, and stir to make the aniline monomer and the bacterial cellulose disperse evenly , to obtain the mixture A;

[0026] 3. Mix the oxidizing agent with a hydrochloric acid solution with a concentration of 1mol / L to obtain a mixed solution B; add the mixed sol...

specific Embodiment approach 2

[0034] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the bacterial cellulose is bacterial cellulose leftovers. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0035] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the condition of the ultrasonic cleaning in step 1 is ultrasonic time of 10 hours, and the deionized water is replaced every hour. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com