Method for aligning iron discharged from blast furnace and molten iron tanks below blast furnace

A blast furnace tapping and molten iron tank technology, applied in the direction of discharge devices, etc., can solve the problems of equipment resources and energy waste, injury, molten iron splashing, etc., to ensure equipment and personal safety, prevent misoperation, and save costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0043] The invention relates to a blast furnace tapping method and an alignment method for a molten iron tank under the furnace, comprising the following steps:

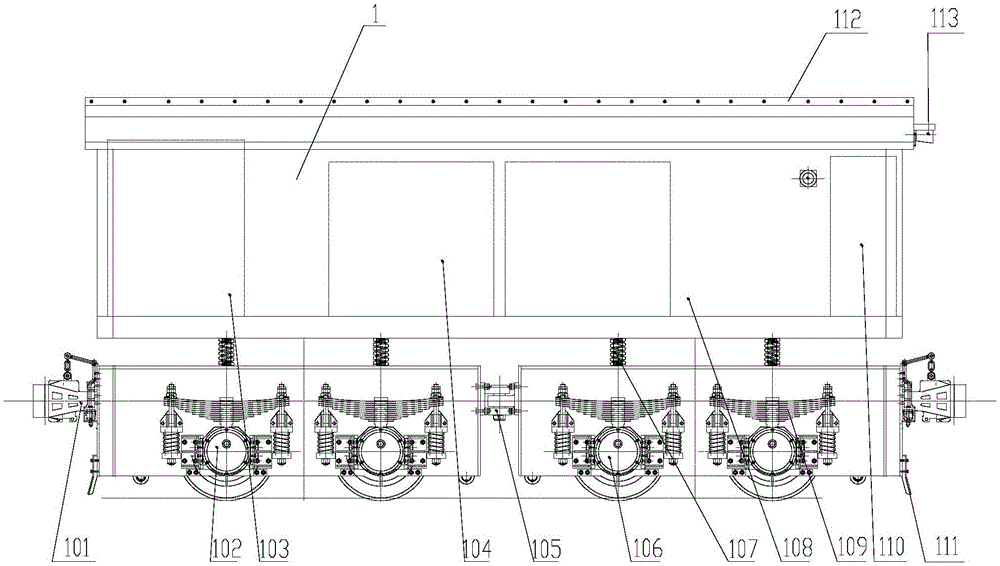

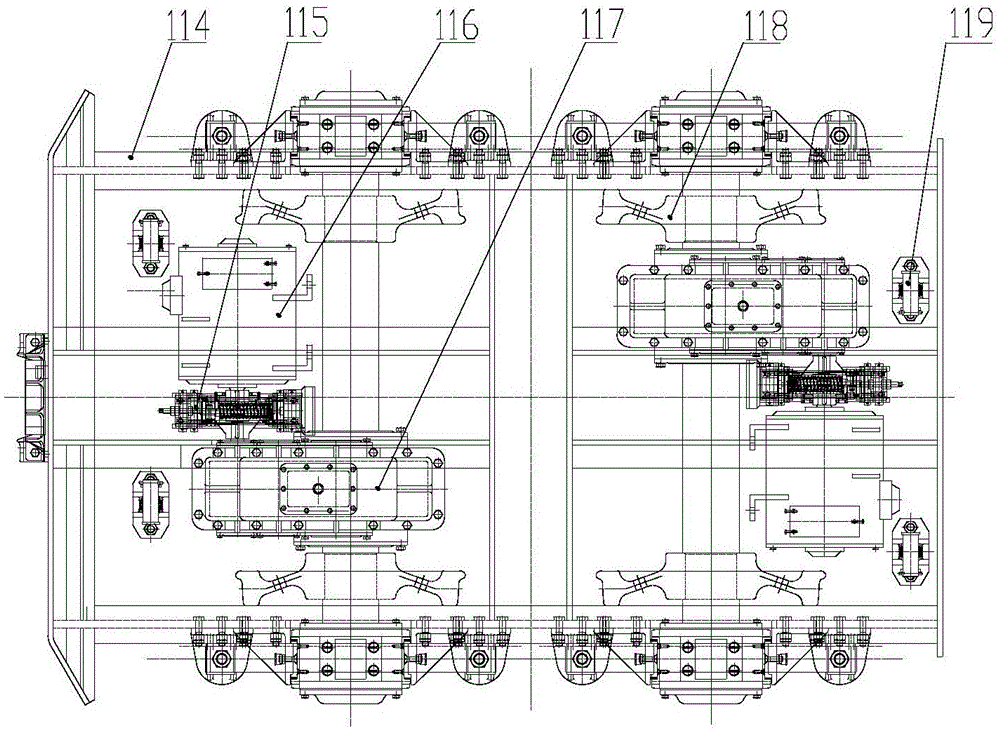

[0044] 1) First, the multiple empty iron ladles 15 are transported by the diesel locomotive to the bottom of the blast furnace 2, and the empty iron ladles 15 are distributed in proportion to the rails 14 corresponding to the two iron ladle alignment tractors 1 paralleled under the same taphole Above, the hot metal tank car is connected with the hot metal tank alignment tractor 1 through the coupler connection buffer device 101;

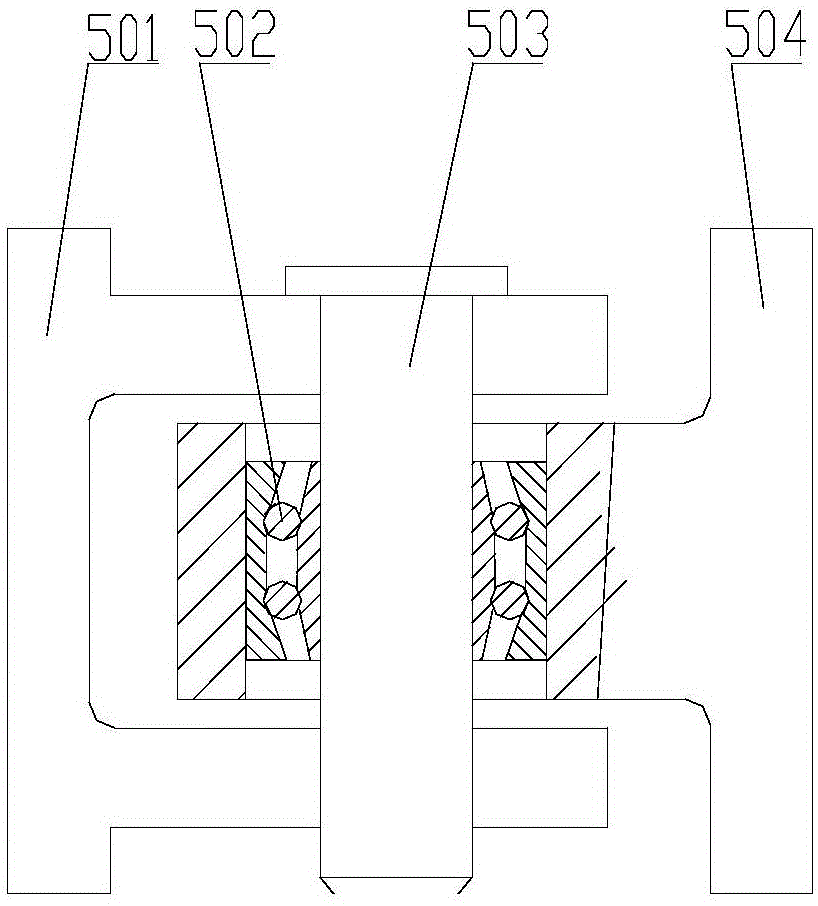

[0045] 2) if Figure 5 As shown, on the tapping platform 16 above the rails 14 of each column, the industrial high-temperature-resistant electronic tag 17 is installed next to the molten iron tank observation window 18 through a fixed bracket, and the molten i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com