Cloth dyeing machine with stirrers

The technology of agitator and dyeing machine is applied in the processing of textile materials, textile and paper making, and equipment configuration for processing textile materials. The effect of secondary damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

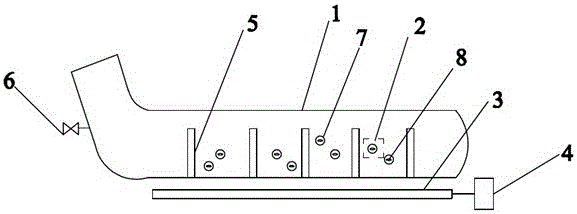

[0011] Such as figure 1 As shown, the cloth dyeing machine with agitator has a structure including a base, and is characterized in that it also includes a cloth dyeing body 1, a magnetic controller 4, a magnetic sensor 3, and several agitators 2, and the dyeing body 1 is A cylindrical shape with a hook, on which an overflow prevention hole 6 is provided, the stirrer includes a stirrer 8, a protective cover 7, a cross section of the stirrer 8 is elliptical, and its material is a magnetic substance, so The protective cover 7 is hollow spherical, and the surface is covered with a number of round holes. The protective cover 7 is divided into two semicircles, and the two semicircles are connected to each other by threads. The magnetic sensor 3 is located below the stirrer, and The magnetic controller is connected to 4, and the magnetic controller 4 is located under the dyeing body 1.

[0012] More specifically, the protective cover 7 is provided with a buckle, and the buckle is lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com