Railway vehicle brake disc plate and combined warping prevention shaft-mounted brake disc

A technology for rail vehicles and brake discs, applied in the directions of brake discs, brake types, brake components, etc., it can solve the problems of axial warping deformation, disassembly obstacles, and eversion of joints, so as to improve the connection strength and strengthen The effect of integrity and high connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

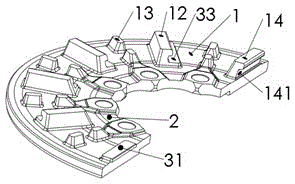

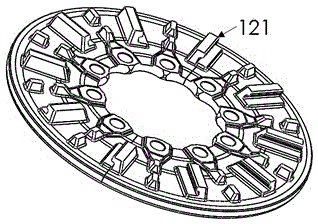

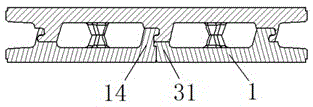

[0026] refer to figure 1 , a rail vehicle brake disc, comprising: a semi-annular disc 1, a flange 2 is connected to the inner ring of the semi-annular disc 1, and through holes are arranged on the flange 2 and the through holes are uniformly distributed in the circumferential direction, Wide cooling ribs 12 and narrow cooling ribs 13 are evenly distributed on the semi-annular disk 1 in the circumferential direction, quasi-wide cooling ribs 14 are provided at one end of the semi-annular disk 1, and a boss 31 is provided at the other end of the semi-annular disk 1. The boss 31 extends along the circumferential direction of the semi-annular disc 1 and forms a protruding part of the boss protruding from the other end of the semi-annular disc 1 , and a radial groove 141 which doubles as a circumferential connection is provided on the quasi-wide cooling rib 14 Moreover, the radial groove 141 also used for circumferential connection can accommodate the protruding portion of the boss ...

Embodiment 2

[0028] see Figure 5, a combined anti-warping shaft-mounted brake disc, including a disc hub 4 and two brake disc bodies respectively arranged on both sides of the disc hub 4 and fixed with the disc hub 4, the brake disc body consists of 2 The brake discs of rail vehicles are connected to each other. The fixing of the disc hub 4 and the brake disc body is a common fixing method in the prior art. Specifically, elastic pins 5 can be set on the hub 4 to realize the disc body The axial positioning of the disc hub 4 and the brake disc body are fixed by fasteners such as bolts;

[0029] refer to figure 1 , the rail vehicle brake disc comprises a semi-annular disc 1, a flange 2 is connected to the inner ring of the semi-annular disc 1, and a through hole is arranged on the flange 2 and the through holes are uniformly distributed in the circumferential direction, and in the semi-annular disc 1 The annular disk 1 is evenly distributed with wide cooling ribs 12 and narrow cooling ribs...

Embodiment 3

[0033] see Figure 5 , a combined anti-warping shaft-mounted brake disc, comprising a disc hub 4 and two brake disc bodies respectively arranged on both sides of the disc hub 4 and fixed to the disc hub 4, the brake disc body consists of 2 The rail vehicle brake discs are connected to each other;

[0034] refer to figure 1 , the rail vehicle brake disc comprises a semi-annular disc 1, a flange 2 is connected to the inner ring of the semi-annular disc 1, and a through hole is arranged on the flange 2 and the through holes are uniformly distributed in the circumferential direction, and in the semi-annular disc 1 The annular disk 1 is evenly distributed with wide cooling ribs 12 and narrow cooling ribs 13 in the circumferential direction. One end of the semi-annular disk 1 is provided with quasi-wide cooling ribs 14, and the other end of the semi-annular disk 1 is provided with a boss 31. The boss 31 extends along the circumferential direction of the semi-annular disk 1 and for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com