A sliding device between layers of a laminated shear box

A sliding device, shear box technology, applied in measuring devices, vibration testing, testing of machine/structural components, etc., can solve the problems of small friction coefficient, low reliability, etc., to achieve stable performance, safe and reliable use, installation and reliability. Apply convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

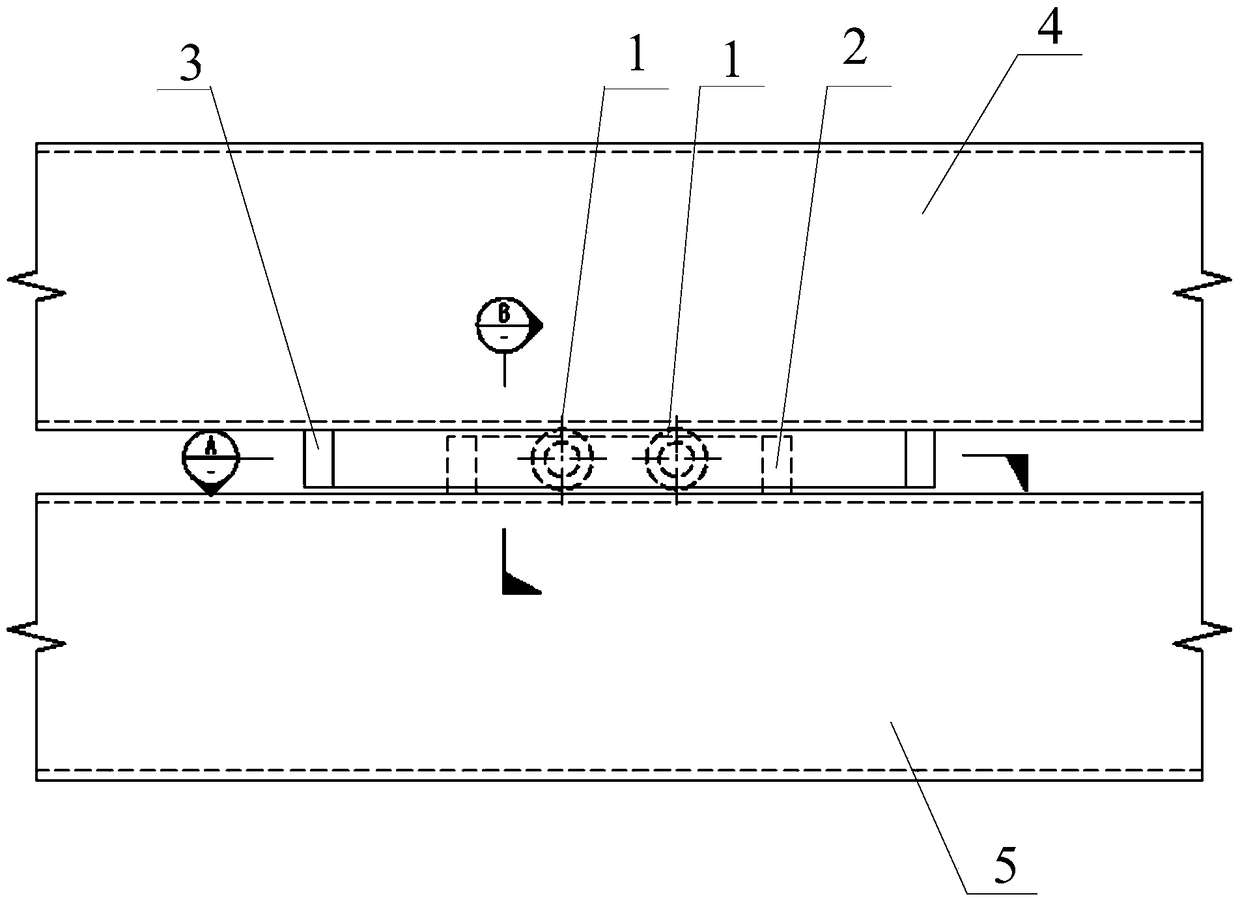

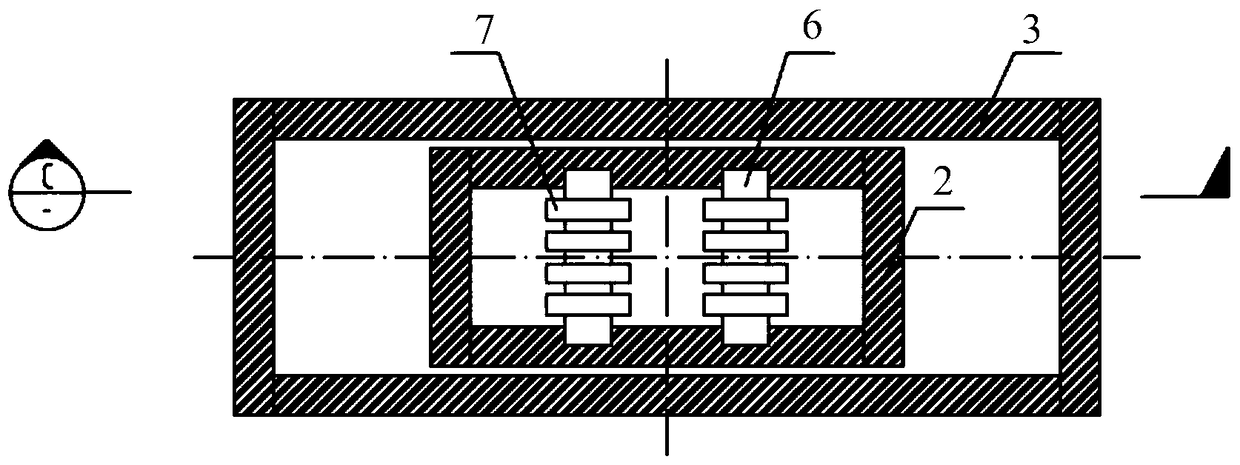

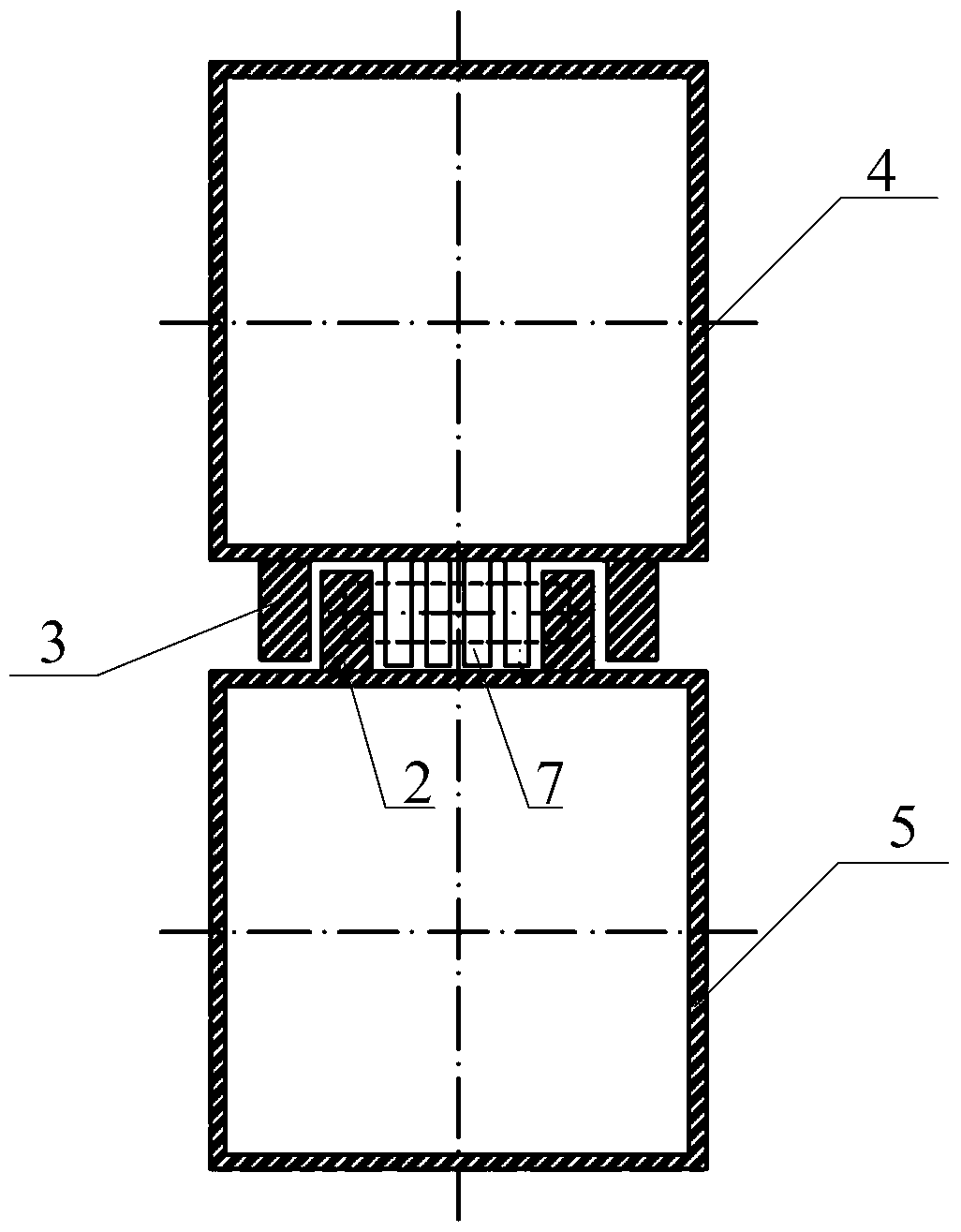

[0019] In order to solve the technical problem of the low reliability of the existing roller and ball interlayer sliding methods used in the laminated shear box, an embodiment of the present invention provides an interlayer sliding device for the laminated shear box, The general idea is as follows:

[0020] The interlayer sliding device is composed of guide grooves, fixing grooves and sliding components. The guide grooves are fixed on the bottom of the upper steel frame, the fixing grooves are fixed on the top of the lower steel frame, and the sliding components are set in the fixing grooves.

[0021] Through the interlayer sliding device of the above structure, before the stacked shear box shaking table test, the fixing groove needs to be inserted into the guide groove when the two layers of steel frames are superimposed, and driven by the sliding component, the adjacent two layers of steel frames The relative slip between them will follow the track in the guide groove, reali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com