Fracture-cavity reservoir inter-well communication passage and flow parameter characterization method

A technology for connecting channels and flow parameters, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve the problems of unfeasible operation, increasing the complexity of karst channel parameters, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0177] Example 1: TK221 well group.

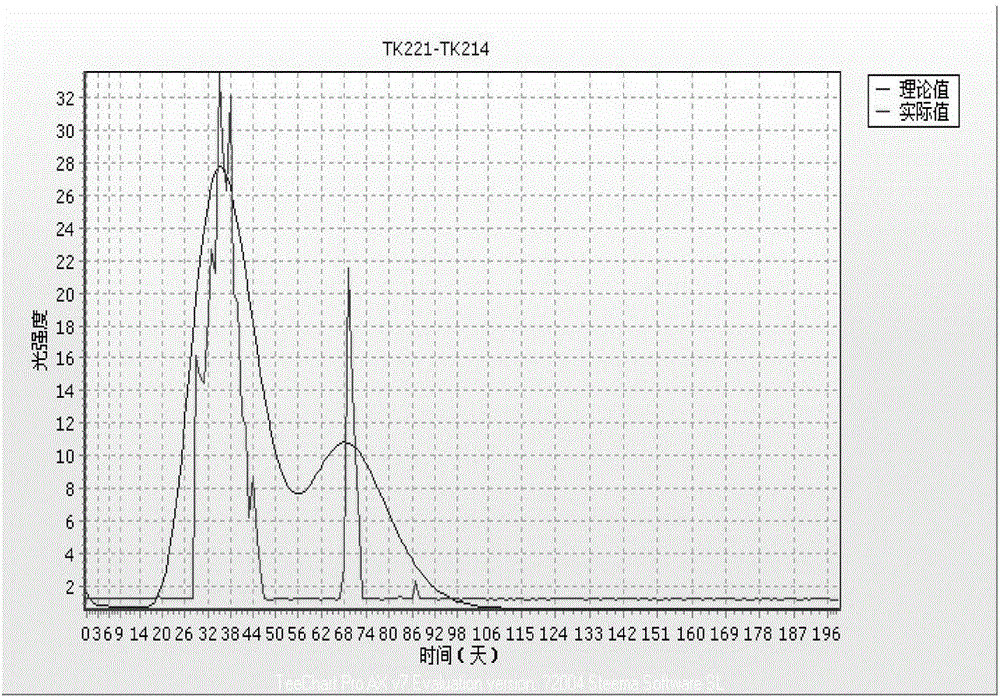

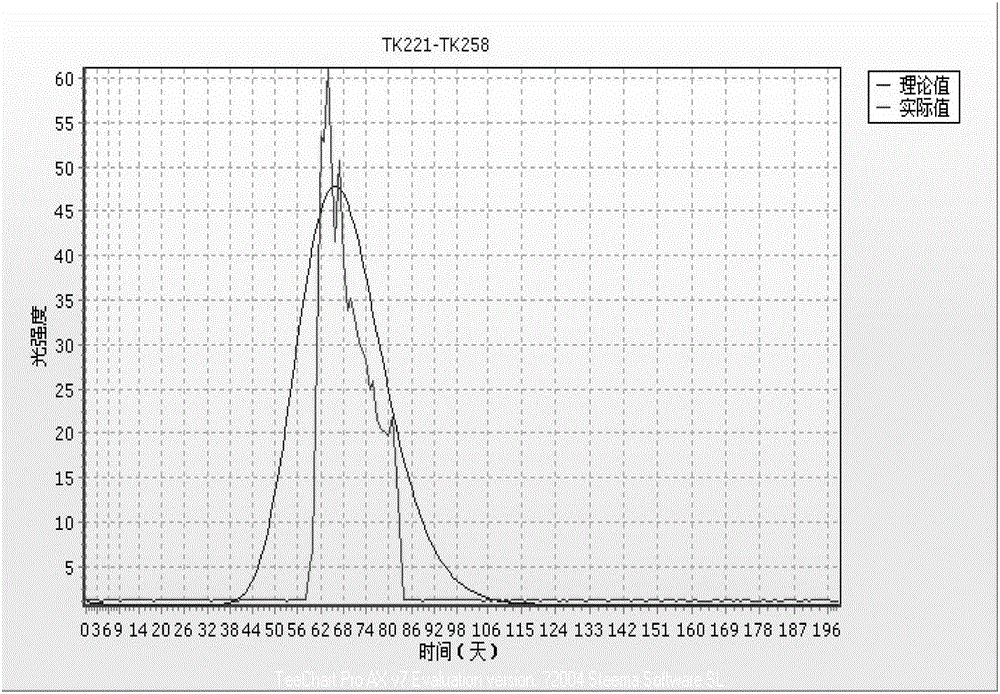

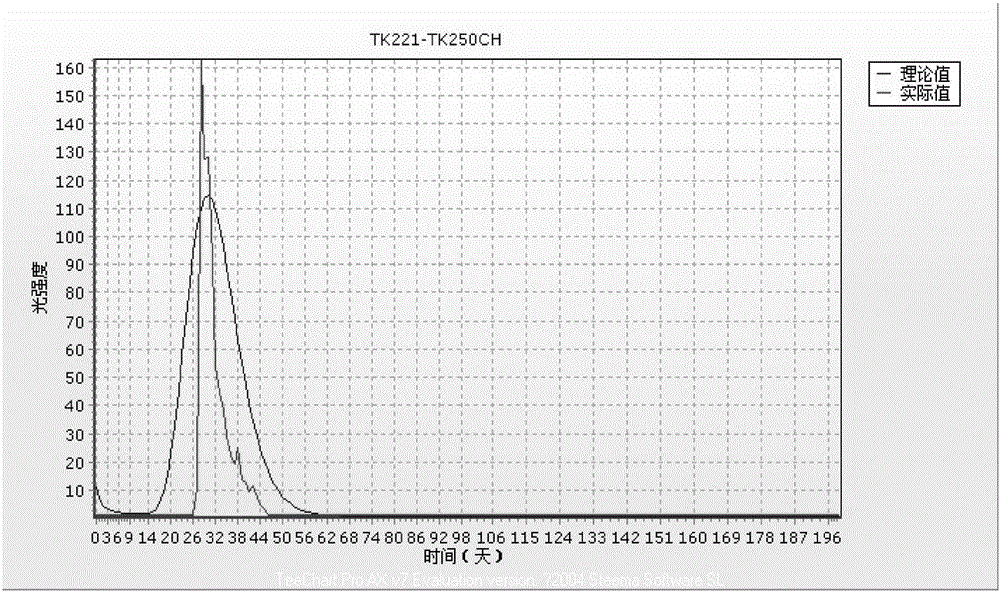

[0178] The injection well is TK221, corresponding to 4 tracer production wells TK214, TK258, TK250CH, TK251CH during the monitoring period. From the tracer curves, well TK214 detected two independent peaks, indicating that there were two independent communication channels between wells TK221 and TK214, and the tracer curves monitored by the other three wells were all single-peak curves, indicating that each injection The communication channel between production wells is a single channel, such as figure 1 , 2 , 3,4 shown in the measured curve. The basic data used for fitting are shown in Table 1 (the data of each point on the measured trace curve are omitted)

[0179] Table 1 Basic parameters of tracer curve fitting of well group TK221

[0180]

[0181] The well group fitting results are shown in Table 2 and figure 1 , 2 , 3,4 in the theoretical curve.

[0182] Table 2 Calculation results of connection parameters of TK221 well gro...

Embodiment 2

[0186] Embodiment 2: TK634 well group.

[0187] The injection well is TK634, corresponding to 7 tracer production wells TK747, TK744, TK711, TK625, T7-607, S80, and TK667 during the monitoring period. The well area is an area where weathering crust is developed. From the measured trace curves, the trace curves of each well are composed of several random small wave peaks, reflecting that the flow space between injection and production wells is actually formed by many small connecting channels. Parallel channel structures such as Figures 5 to 11 The shape of the measured curve is shown in the middle.

[0188] The measured curve can be approximated as having several main peaks according to the needs of interpretation. Well TK214 detected two independent peaks, indicating that there were two independent communication channels between wells TK221 and TK214, and the tracer curves monitored by the other three wells were all single-peak curves, indicating that the communication cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com